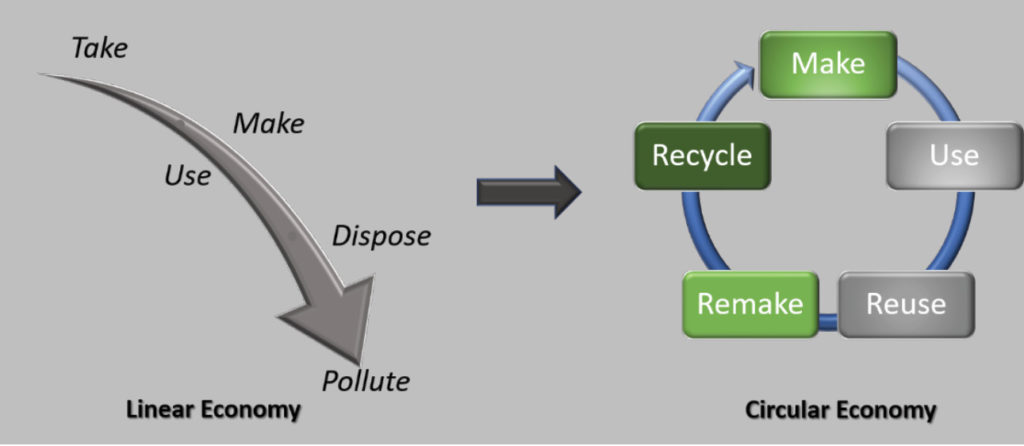

I recently attended PACK EXPO and listened to numerous talks at the Innovation Showcase on how the packaging industry is responding to growing consumer demand for sustainable packaging. “Reduce—reuse—recycle” now encompasses a cradle-to-cradle approach to sustainability and is referred to as the circular economy. A circular economy, an economic system aimed at eliminating waste and the continual use of resources, is based on three principles:

- Design out waste and pollution;

- Keep products and materials in use;

- Regenerate natural systems.

Consumers increasingly believe that companies should address environmental issues, especially as they relate to the proper disposal of plastics. As the Ocean Conservancy reports (www.oceanconservancy.org/

trash-free-seas/plastics-in-the-ocean), at least eight million metric tons of plastic end up in the ocean every year. This is the equivalent of dumping one garbage truck every minute into the ocean. At that rate, by 2050, there would be more weight in garbage than fish! Obviously, this is not a sustainable practice if we care about our planet. Retailers are responding by setting their own sustainability goals. For example, Walmart wants to achieve 100% recyclable, reusable, or compostable packaging for private brands by 2025. Target is working with its suppliers to change how they produce, use, and reuse plastic packaging, and PepsiCo is working towards 100% recyclable, compostable, or bio-degradable packaging by 2025. In addition, national and regional governments in the United States and Europe are mandating sustainable solutions through laws and ordinances to reduce plastic waste.

Packaging material suppliers are working on innovative approaches to increase their participation in the circular economy. Increasingly, raw materials used to produce plastics are bio-renewable and compostable. Even university researchers are heeding the call by submitting grant proposals focused on using carbohydrate-based chemicals to produce plastics. As this chemistry becomes commercially available, packaging suppliers will offer more biobased options for the market. In the meantime, suppliers are lightweighting plastic containers by removing plastic from bottles and using unique shapes and forms to add strength where needed. They are utilizing sophisticated software tools to redesign packaging to increase stack height to ship more freight per truckload. Container suppliers are also adding more post-consumer recycled materials to their bottles. Compostable smart adhesives are beginning to emerge for use on paper stock, plastics, and fibers to ensure a good quality certified compost. In short, packaging suppliers are working through the entire value chain to support the circular economy.

Packaging innovation in the paint and coatings industry began in 1877 when Sherwin-Williams patented the resealable paint can. Although the paint can is recyclable, improvements to product packaging can also increase recycling efforts. This can be done by designing more efficient pallet patterns, using less plastic shrink wrap, eliminating secondary overwraps, and reducing cardboard usage. Similar to the packaging industry, the coatings industry can participate in the circular economy through more effective use of materials throughout its entire value chain.

Dr. Victoria Scarborough is owner and principle advisor at Materia Prima Ventures; (vscarborough@matprimeve.com)

CoatingsTech | Vol. 16, No. 11 | November/December 2019