By Jacob D. Shevrin, Evonik Corporation

As global environmental regulations continue to tighten restrictions on coatings containing volatile organic compounds (VOCs), the need for hydrolytically stable additives in waterborne coatings has never been greater.

Organofunctional alkoxysilanes are a class of widely used additives in the coatings industry. They act as a bridge between an organic coating and an inorganic substrate, providing adhesion promotion and other important performance improvements.

Given the high moisture sensitivity of organofunctional alkoxysilanes, most silane additives rapidly undergo condensation in waterborne coatings, leading to unworkable viscosities and gelling of the waterborne coatings within the first few weeks or months on the shelf. This has posed a significant barrier to using silane additives in waterborne coatings for all types of applications.

Two organofunctional silane additives that demonstrated positive hydrolytic stability over an extended period of time in waterborne acrylic roof coatings are investigated here.

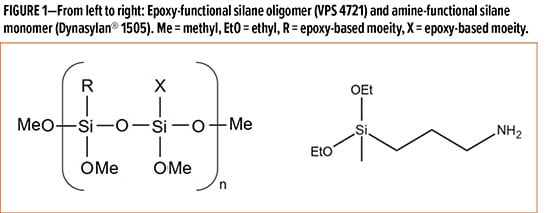

These organofunctional silane additives include an epoxy-functional silane oligomer, VPS 4721, and an amine-functional silane monomer, Dynasylan® 1505 (Figure 1).

These organofunctional silane additives include an epoxy-functional silane oligomer, VPS 4721, and an amine-functional silane monomer, Dynasylan® 1505 (Figure 1).

The oligomeric structure of the epoxy-functional silane oligomer allows for slower hydrolysis and condensation rates in a waterborne system compared to a monomeric epoxy-functional silane (such as glycidoxypropyltrimethoxysilane).

Furthermore, the epoxy groups on this silane oligomer may break open into diols in the presence of water, allowing for further stability in water over time. The presence of only two ethoxy groups and one methyl group on the amine-functional silane monomer allows for a slower, two-dimensional crosslinking mechanism when hydrolysis and condensation occur in a waterborne system. The primary amine group on this amine-functional silane monomer also shows positive stability in waterborne systems.

As the liquid-applied, cool-roof coating market continues to grow (specifically liquid-applied waterborne acrylic cool-roof coatings), this article will focus on the liquid-applied waterborne acrylic roof coating market. It will demonstrate that with the use of stable organofunctional silane additives, several crucial performance characteristics of waterborne acrylic roof coatings can be improved.

The mechanism behind an organofunctional silane adhering to a roofing membrane surface is an important process to understand before investigating the performance of the organofunctional silane additives into the waterborne acrylic roof coatings.

Organofunctional silanes contain a hydrolysable alkoxysilane (Si-OR) functional group that can bond with inorganic surfaces. In this work, the organofunctional silanes to be investigated have silicon functional groups that consist of alkoxy groups, typically ethoxy or methoxy groups.

Organofunctional silanes also consist of an organofunctional group that can react with organic systems, such as an acrylic resin. The simultaneous reaction of the silicon functional groups and organofunctional groups allow organofunctional silanes to act as an adhesion promoter between inorganic and organic materials.

For an organofunctional silane additive to provide adhesion promotion of a waterborne acrylic roof coating to a roofing membrane, hydrolysis must first take place at the alkoxy sites to form silanol groups. This process occurs within the first few hours of the organofunctional silane being added into a waterborne acrylic roof coating, given the excess water in this type of coating.

When the hydrolyzed organofunctional silane contacts an inorganic surface, the silanol groups can initially form hydrogen bonds with the hydroxyl groups on the inorganic surface. Upon removal of moisture from the system, these hydrogen bonds can form siloxane bonds between the organofunctional silane and roofing membrane. These siloxane bonds provide the strong adhesion characteristics that organofunctional silanes are known to have.1

Furthermore, siloxane bonds can form between silanol groups within the waterborne acrylic roof coating upon application, providing an increased crosslinking density for the coating that can lead to improved mechanical properties and other critical roof coating characteristics.

Several key coating properties will be investigated in accordance with ASTM D6083, the standard for liquid applied waterborne acrylic roof coatings.2 This includes shelf stability, dry and wet adhesion properties to various roofing membranes, ponding water resistance, dirt pickup resistance, tensile strength, flexibility, and UV weathering resistance.

CONTINUE READING IN THE SEPTEMBER 2021 DIGITAL ISSUE OF COATINGSTECH

REFERENCES

CoatingsTech | Vol. 18, No. 9 | September 2021