By Jan Nordin, Olof Sandin, and Peter Greenwood, Akzo Nobel Pulp and Performance Chemicals AB, Sweden

Hollow ultra-low density thermoplastic microspheres can be used as filler in elastic waterproof/cool roof coatings to improve a number of important properties of the coatings. Micron-sized hollow microspheres have a surprisingly strong effect on reflecting solar radiation and reducing the temperature of cool roof coatings. Results from solar reflectance measurements show that the coating system filled with hollow microspheres reflects solar radiation of all incoming wavelengths. Hollow microspheres can be combined with reflecting pigments, making it possible to formulate coatings with extremely high values for total solar reflectance (TSR).

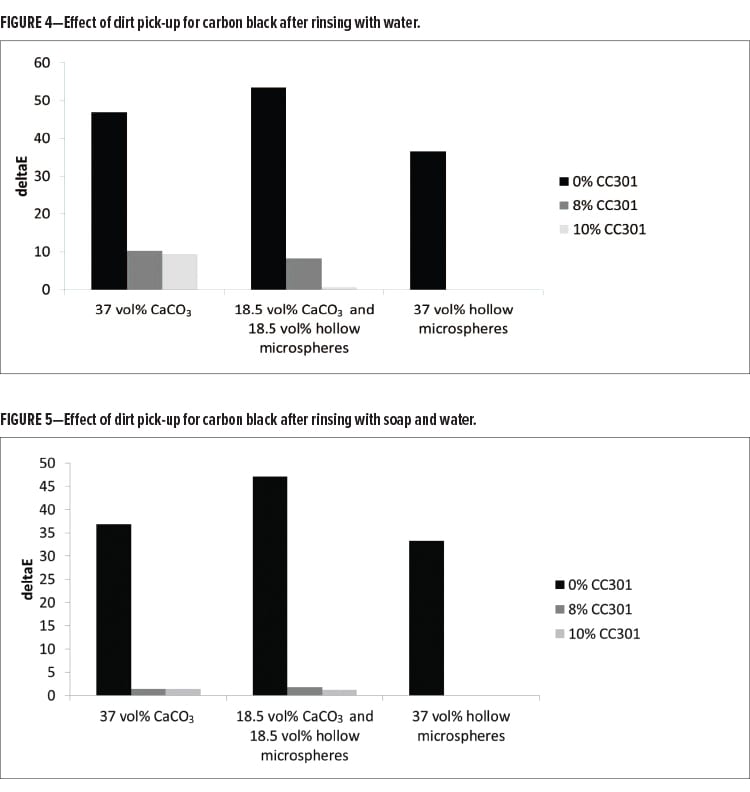

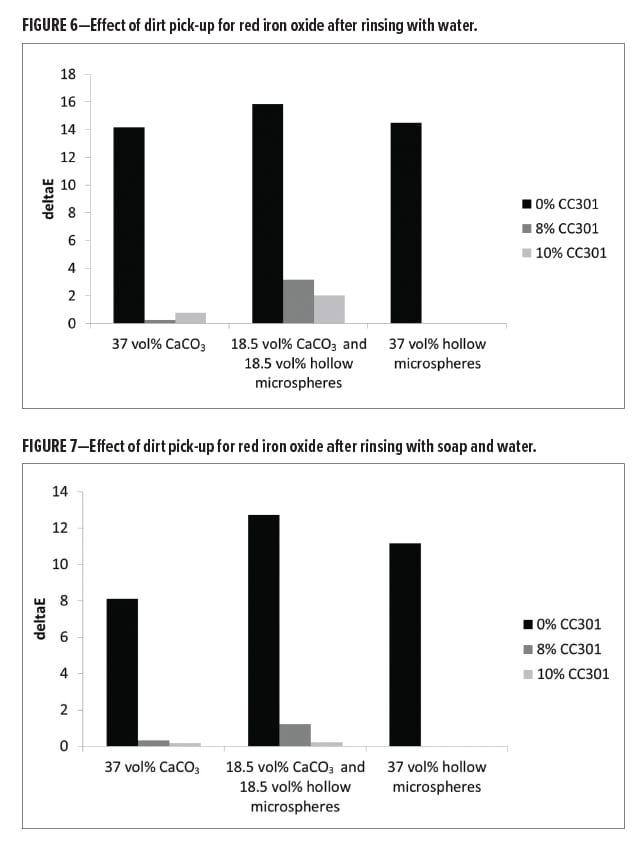

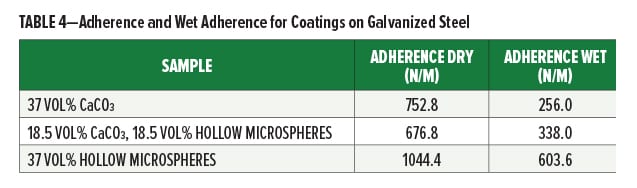

Dirt pick-up resistance (DPUR) is not significantly affected by the choice of filler for the formulations evaluated here. This article presents convincing results that DPUR can be drastically improved by adding surface modified silica nanoparticles to the formulations. The silica nanoparticles tend to migrate to the coating surface and affect both the surface energy and the tackiness of the surface.

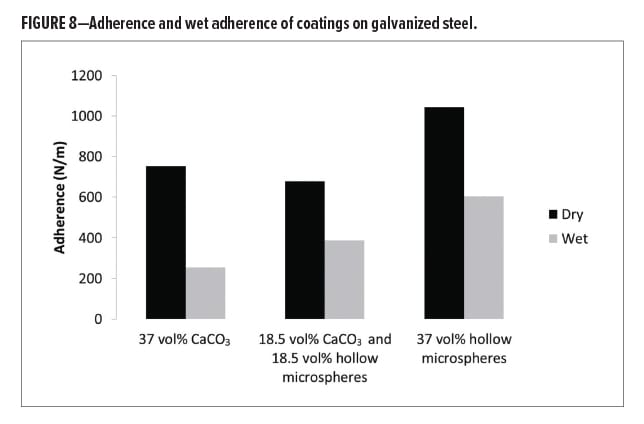

Adhesion to steel surfaces is significantly improved by exchanging the inorganic filler for thermoplastic hollow microspheres. This effect is true for both wet and dried coatings and will help improve the water-proofing properties of the coating. It is likely that the thermoplastic properties of the hollow fillers count for part of this effect.

INTRODUCTION

Air conditioning accounts for up to 70% of residential energy consumption in warm, sunny areas of the world.1-4 Energy consumption by AC is concentrated to a few hours of the day, and the peak energy demand puts high stress on power distribution systems. Not only is it a power distribution problem, but the high energy consumption is an unwanted cost and contributes to the increase of CO2 levels in the atmosphere when fossil fuels are used for energy production.

One way to reduce heat-up of buildings is to use cool roof coatings.3 Cool roof coatings help reduce the heat-up of buildings mainly due to their high solar reflecting properties. By reducing the cooling energy use in buildings, we have the potential to reduce power plant emissions, significantly ease the power distribution problem, and save money on electricity. Cool roof coatings are designed to reflect a significant part of the energy from the sun, often aided by the addition of a reflecting pigment like titanium dioxide (TiO2).4 Hollow microspheres have been used as filler in cool roof coatings for more than 15 years. For many years, the general perception was that the major benefit came from their contribution to thermal insulation. Recent research has proven that one of the more unexpected characteristics of hollow microspheres is that they also provide efficient cooling effect by reflecting solar energy.5

Because of the wide temperature cycles of external roofs over a day, cool roof coatings are often formulated with relatively soft binders that give the coatings elastomeric properties. The coatings should have the ability to move with the substrates that expand in the heat and contract when the roof cools off at night. Highly filled coatings normally lose a great part of the elasticity that comes with the binder.

Expancel® Microspheres are thermally expandable core/shell particles in which a blowing agent, typically a low-boiling hydrocarbon such as isobutane, is encapsulated by a thermoplastic polymer shell.6-8 Heated above the glass transition temperature (Tg) of the polymer shell, the internal pressure from the encapsulated blowing agent causes the microsphere to expand to about four times the diameter and about 60 times in volume. The expanded form is retained upon cooling, and the density of the microspheres can be reduced from about 1100 kg/m3 down to around 30 kg/m3. Thermally expandable microspheres are available in different forms. Pre-expanded microspheres are commonly used in many coating applications, whereas expandable microspheres can be used in applications in which the process involves heating sufficient to expand the microspheres. Expanded thermoplastic microspheres are available with particle size down to 20 µm. They do not absorb water due to the extremely tight polymer shell, and they show resilient properties, also at temperatures well below 0ºC.

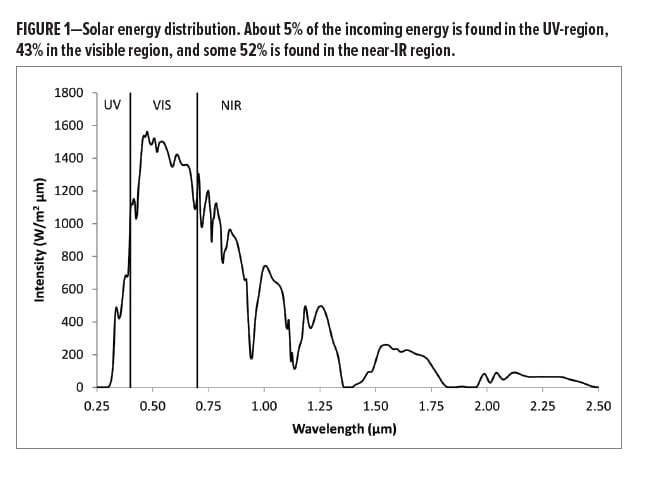

Elastomeric cool roof coatings are typically applied to provide a water-proofing seal on the roof and to reduce absorption of energy from the sun. Waterproofing properties come with high elasticity, good adherence to the substrate, and low water absorption. To achieve superior solar reflective properties, it is important to reflect not only visible light, but also light in the near-infrared region as nearly half of the incoming solar energy that hit the surface of the earth is near-infrared radiation (NIR) (Figure 1).

The diffuse reflection in a system of pigment particles is a combination of refraction and diffraction phenomena. Refraction is the bending of light travelling through a particle and is predominantly determined by the difference in refractive index of the pigment particle and the surrounding media, which is why a rutile (TiO2) particle system is so efficient. Diffraction is the bending of light passing near the particle and is very dependent on particle size. The pigment diameter should be slightly less than one-half the wavelength of the light to be scattered.9-10 This relation implies that for a dispersion of TiO2 pigment particles optimized to reflect visible light (i.e., a high opacity system), reflection power reduces drastically for longer wavelengths. In fact, for near-infrared radiation, TiO2 and CaCO3 often show similar reflective properties.5 The effect from TiO2 can be improved by increasing the addition level, optimizing interaction with various extenders,11 and by using TiO2 with broader particle size distribution. It is possible to improve reflection in the NIR region by broadening the size distribution on the coarse side.9-10 Although this is technically possible, associated raw material costs are substantial and the CO2 footprint becomes bigger.

Sandin et al.5 demonstrated that exchanging part of the inorganic filler with micron-sized hollow microspheres provides a reflective system with good reflection over the entire solar spectrum (UV-VIS-NIR).5 Hollow microspheres particularly stand out from other additives in how they reflect radiation in the near-infrared region. Hollow microspheres reflect light in the same way as foam on a beer. The refractive index of the gas inside the microspheres is close to 1.0, whereas the binder has a refrective index of about 1.5. The difference in refractive index explains the light scattering effect of the bubbles. The particle size of the hollow microspheres is important for the total solar reflection (TSR). By decreasing the average particle size of the spheres, the solar reflectance is increased as smaller microspheres result in a larger number of microspheres in the coating, for a given volume added. Unlike TiO2, the particle size of the bubbles does not have a significant effect on relative reflection over different wavelengths. These results are consistent with the reflection properties of foam.5 Thus, by using micron-sized, hollow microspheres in combination with TiO2, it is possible to formulate cost-effective cool roof coatings having excellent reflective properties also in the NIR region. Reflection in the invisible near-infrared region is important, as just over 50% of the energy from the sun is NIR.

This article intends to confirm that by using micron-sized hollow microspheres as filler in coatings, it is possible to enhance the reflection of solar radiation considerably. The article will also describe the effect of the filler on dirt pick-up resistance (DPUR). Results will be presented for the effect on DPUR by combining thermoplastic hollow microspheres with modified colloidal silica. This type of surface-modified silica nanoparticles was previously reported to have a positive effect on DPUR in other types of coatings.12-13

Elastomeric cool roof coatings are also often called elastomeric waterproofing coatings. This is a denotion that says more about the original purpose of these coatings—to seal and waterproof the roof. As the roofing material is exposed to high temperature fluctuations between the hot sunny afternoon and the cool night, waterproofing can be quite a challenge. The temperature variations put extreme stress on the roofing material that expands and contracts every 24 h. It is, therefore, of utmost importance that the coating adheres firmly to the substrate being coated and that the coating expands and contracts with the substrate upon temperature changes. This article will show that by using resilient thermoplastic hollow microspheres, it is possible to improve adherence of the coating to a galvanized steel substrate.

EXPERIMENTAL

This investigation was performed in collaboration with the European Coatings Research Institute in Belgium (CoRI).

The coating formulations were made of acrylic binder (Rhoplex® EC-1791, Dow Construction Chemicals), TiO2 (Kronos International Inc.), ZnO2 (Kadox®915) fillers such as calcium carbonate (CaCO3, Snowhite®12 from Omya/Imerys), and hollow thermoplastic microspheres (Expancel 461WE20 from Akzo Nobel Pulp and Performance Chemicals AB). The average size of the hollow microspheres is approximately 20 µm. Nanosized surface-modified silica (Levasil CC301 from Akzo Nobel Pulp and Performance Chemicals AB) was used in an attempt to improve DPUR. Levasil CC301 is a water-based suspension of surface modified silica nanoparticles. The average particle size of the nanoparticles is 7 nm.

Solar reflectance measurements followed the procedures described in ASTM E309/ASTM G173 and DPUR were conducted for both carbon black and red iron oxide.

Adherence of the coatings to galvanized steel was evaluated for both dry and wetted coatings following ASTM C794 and ASTM D903, respectively. Coatings were applied by brush on galvanized steel in two layers with the cloth strip in between. Dry film thickness was 500 µm and drying time was 14 days at 23°C and 50% relative humidity. For wet adhesion, the samples were submerged in tap water for 168 h prior to testing.

RESULTS AND DISCUSSION

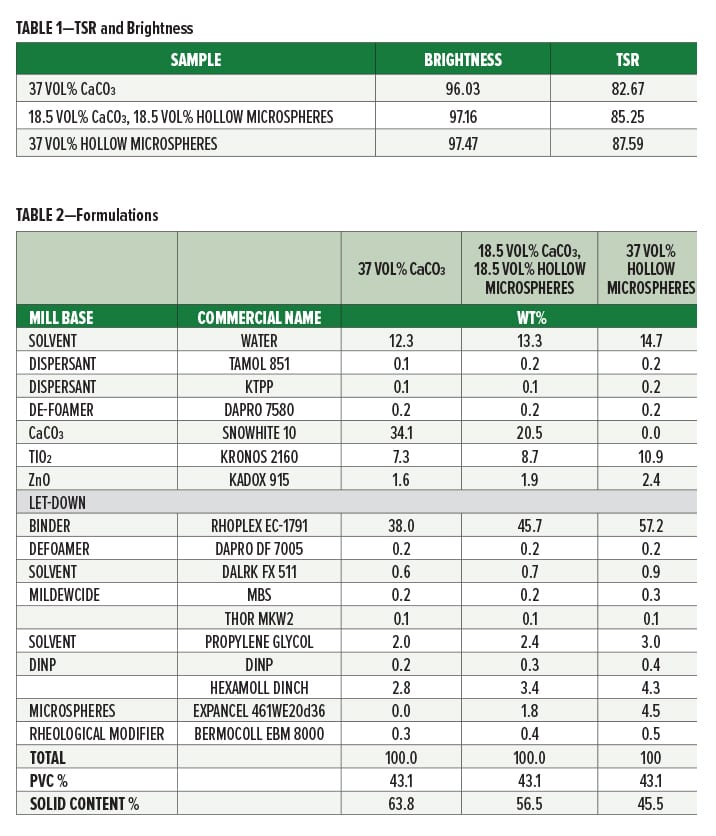

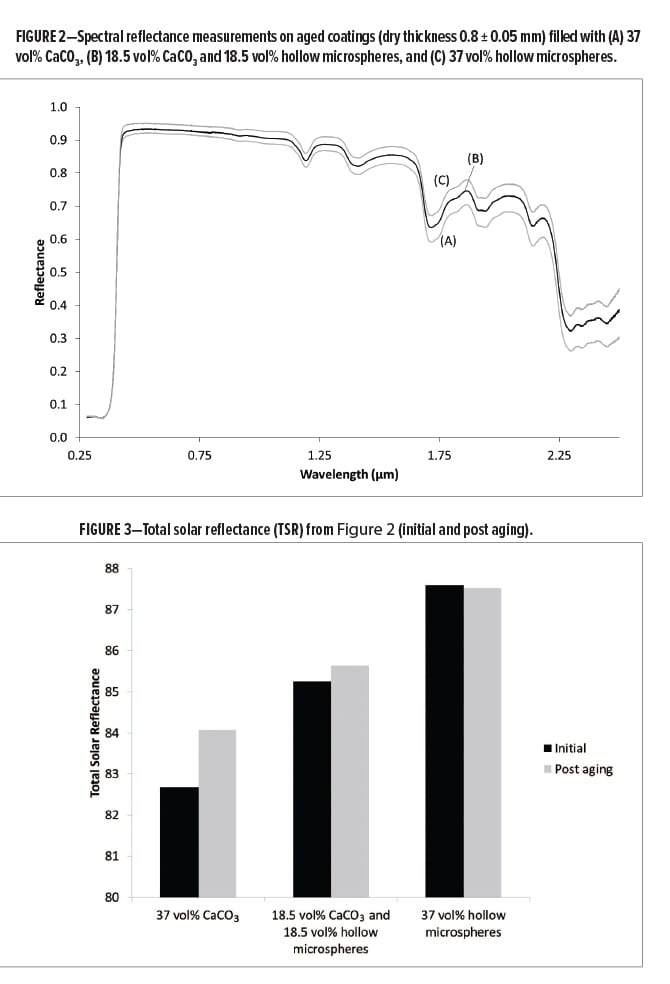

In this study, we have formulated and evaluated elastomeric cool roof coatings with different filler compositions. The reference coating is filled with 37 vol% CaCO3 filler. Coatings were also prepared with a filler combination of 18.5 vol% of the inorganic filler and 18.5 vol.% of the thermoplastic hollow microspheres as well as with 37 vol% hollow microspheres (Tables 1 and 2). Figure 2 shows solar reflective properties of the three coatings; all three have 37 vol% filler and contain 5.4 vol% TiO2. It is obvious from the solar reflection data that the hollow microspheres contribute to the reflection of visible light as well as NIR. The major effect is for the NIR spectrum. The TSR increases from 82.7% to 85.2% to 87.6% by exchanging CaCO3 filler for hollow microspheres by 50% and 100% (Table 1, Figures 2–3). These results agree with results presented by Sandin et al.5 As described in the introduction, the hollow gas-filled microspheres help reflect light in a similar manner as foam, and the scattering effect is, therefore, rather insensitive to the wavelength of the incoming light. Thus, the hollow fillers complement the reflective effect of TiO2 mainly in the near-infrared region. Brightness (L*) is also improved by hollow microspheres as expected from the effect of the foam structure (Table 1). UV aging (1000 h) does not seem to significantly affect TSR (Figure 3).

It is difficult to translate the effect of a higher TSR to the actual temperature effect, or cooling effect, for a building. There are simply too many parameters that affect the actual heat-up of a building; TSR and thermal emittance of the roof and the walls, the angle of the roof, the geometry of the building, thermal conductivity, and thickness of roof and walls are a few parameters that determine heat-up of a building. Martín-Dominguez reported experimental results at ISES Solar World Congress 2011 on differences in heat flow through concrete roofs with different types of coatings. Experiments were conducted in a well-controlled thermostated model house with flat roof. The conference paper14 reports diurnal heat gain reductions of 44% by coating a concrete slab with a white acrylic cool roof coating filled with 30 vol% CaCO3 and 58% by coating the concrete slab with a white acrylic cool roof coating filled with 30 vol% polymeric microspheres. The effect was explained by differences in solar reflection rather than differences in thermal conductivity. It is concluded in the paper that the use of highly reflective and emissive coatings can be the simplest and most economical solution to strongly reduce the energy consumption destined for artificial ambient conditioning. Only in regions with cold climatic conditions is there the need to use conductive thermal insulation. The usage of conductive thermal insulation in hot regions is not only much more expensive, but it also impedes nocturnal passive cooling of houses.

It is difficult to translate the effect of a higher TSR to the actual temperature effect, or cooling effect, for a building. There are simply too many parameters that affect the actual heat-up of a building; TSR and thermal emittance of the roof and the walls, the angle of the roof, the geometry of the building, thermal conductivity, and thickness of roof and walls are a few parameters that determine heat-up of a building. Martín-Dominguez reported experimental results at ISES Solar World Congress 2011 on differences in heat flow through concrete roofs with different types of coatings. Experiments were conducted in a well-controlled thermostated model house with flat roof. The conference paper14 reports diurnal heat gain reductions of 44% by coating a concrete slab with a white acrylic cool roof coating filled with 30 vol% CaCO3 and 58% by coating the concrete slab with a white acrylic cool roof coating filled with 30 vol% polymeric microspheres. The effect was explained by differences in solar reflection rather than differences in thermal conductivity. It is concluded in the paper that the use of highly reflective and emissive coatings can be the simplest and most economical solution to strongly reduce the energy consumption destined for artificial ambient conditioning. Only in regions with cold climatic conditions is there the need to use conductive thermal insulation. The usage of conductive thermal insulation in hot regions is not only much more expensive, but it also impedes nocturnal passive cooling of houses.

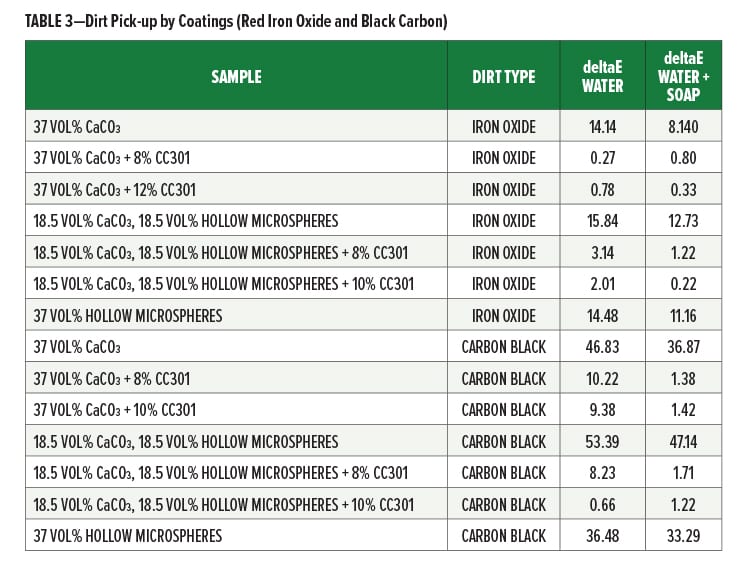

DPUR tests conducted with carbon black and red iron oxide as “dirt components” show similar effects on Delta E for the three coatings with different filler combinations. The relative difference between the coatings does not seem to be significant (Table 3, Figures 4–7). Addition of surface-modified colloidal silica significantly improved the DPUR. This is true for both formulations with CaCO3 and thermoplastic hollow microspheres as filler, and the effect on DPUR increases with higher silica additions. The mechanism responsible for the positive effect of the surface-modified silica on DPUR is described by De Lame, et al.12-13 Surface-modified, nano-sized colloidal silica particles migrate to the surface of the coating to affect surface energy of the coating. If the surface is made more hydrophilic, water will more efficiently remove dirt from that surface, much like a self-cleaning window. The enrichment of silica at the surface of the coating also reduces the tackiness of the coating and prevents dirt from sticking to the surface. This effect is achieved without sacrificing the elastic properties of the coating. The relative effect of the silica in different coatings is most likely determined by a number of factors including the Tg of the binder and the PVC of the coating. It was not the objective of this article to evaluate these parameters.

Adherence and wet adherence on galvanized steel seem to be improved by exchanging the CaCO3 filler for thermoplastic hollow microspheres (Table 4, Figure 8). It is of importance for the waterproofing properties of elastomeric roof coatings that the coating shows excellent adherence to the surface that is coated. There are a number of well-known factors that may positively affect adherence for a coating made from a given binder. Formulating further away from CPVC has a documented positive effect on coating quality including adherence.15-17 Zosel17 reviewed mechanical properties of paint below CPVC and confirmed that the changes in property were approximately proportional to PVC for all observed properties. In this article we chose to compare two physically and chemically very different fillers but with approximately the same CPVC based on calculations from oil absorption (Tables 1–2). Besides the influence of CPVC, many other factors come in to play, such as size, morphology, and chemical nature of filler particles, surface energy, and the resiliency of the filler. The size of filler particles affects not only CPCV, but also surface roughness of the coating, which in turn may affect dirt pick-up and adherence to a substrate. The morphology of the filler particles may also affect both CPVC and surface roughness, but the effect on adherence is more difficult to predict. It is likely that polymeric fillers with relatively low Tg for the polymer contribute more to the adherence of the coating than do inorganic fillers. This comes with the tackier nature of the system. For the same reason, it is likely that a system with polymeric fillers is keener on picking up dirt, especially if the coating system is formulated closer to CPVC. The thermoplastic hollow microspheres studied in this work are made of acrylic polymer material (Tg~101ºC) and are expected to be quite compatible with the acrylic binder. The resilient properties of the thermoplastic hollow microsphere may also help flexibility and compatibility. Adhesion is likely affected by a combination of these factors. Nonspherical inorganic fillers with relatively high aspect ratio may on the other hand introduce a reinforcing effect which spherical fillers fail to provide.

CONCLUSIONS

The results confirm that the thermoplastic micron-sized hollow microspheres reflect solar radiation much better than the CaCO3 filler. Total solar reflectance of the coatings was increased by exchanging by volume the calcium carbonate for thermoplastic hollow microspheres. Hollow microspheres reflect radiation over a wide wavelength range and the effect is significant for visible light and specifically for near-infrared radiation. Modified colloidal silica can be used to improve the dirt pick-up resistance of elastomeric cool roof coatings. A probable explanation to the increased resistance to dirt is that the modified silica particles migrate to the coating surface and affect surface energy and tackiness of the coating. The more hydrophilic character of the coating surface helps keep the surfaces cleaner.

The resilient properties and the thermoplastic character of the hollow microspheres seem to help improve the adherence of the coating to galvanized steel.

Acknowledgments

The authors would like to thank Celine de Lame at the European Coatings Research Institute (CoRI) in Belgium.

References

1. Mirzaei, P.A. and Haghighat, F., “Approaches to Study Urban Heat Islands–Abilities and Limitations,” Build. and Environ., 45 (10) 2192-2201 (2010).

2. Oke, T.R., Johnson, T.G., Steyn, D.G., and Watson, I.D., “Simulations of Urban Heat Island Under ‘Ideal’ Conditions at Night Part 2: Diagnosis of Causation,” Bound-Lay. Meteorol., 56 (4) 339-358 (1991).

3. Synnefa, A., Santamouris, M., and Apostolakis, K., “On the Development, Optical Properties and Thermal Performance of Cool Colored Coatings for the Urban Environment,” Sol. Energy, 81 (4) 488-497 (2007).

4. Akbari, H., Pomerantz, M., and Taha, H., “Cool Surfaces and Shade Trees to Reduce Energy Use and Improve Air Quality in Urban Areas,” Sol. Energy, 70 (3) 295-310 (2001).

5. Sandin, O., Nordin, J., and Jonsson, M., “Reflective Properties of Hollow Microspheres in Cool Roof Coatings,” J. Coat. Technol. Res., 14 (4) 817-821 (2017).

6. Morehouse Jr., D.S., Midland, M., and Tetreault, R.J., “Expansible Thermoplastic Polymer Particles Containing Volatile Fluid Foaming Agent and Method of Foaming the Same,” US Patent 3,615,972 (1971).

7. Kawaguchi, Y. and Oishi, T., “Synthesis and Properties of Thermoplastic Expandable Microspheres: The Relation Between Crosslinking Density and Expandable Property,” J. Appl. Polym. Sci., 93 (2) 505-512 (2004).

8. Jonsson, M., Nordin, M., Malmström, M., and Hammer, C., “Suspension Polymerization of Thermally Expandable Core/Shell Particles,” Polymer, 47 (10) 3315-3324 (2006).

9. McNeil, L.E. and French, R.H., “Multiple Scattering from Rutile TiO2 Particles,” Acta Mater., 48 (18-19), 4571-4576 (2000).

10. Thiele, E.S. and French, R.H., “Light-Scattering Properties of Representative, Morphological Rutile Titania Particles Studied Using a Finite-Element Method,” J. Am. Ceram.Soc., 81 (3) 469-79 (1998).

11. Dietz, P.F., Eur. Coat. J., (14) 07-08 (2003).

12. De Lame, C., Claeys, J.M., Greenwood, P., and Lagnemo, H., “Architectural Coatings,” PPCJ (Jan. 2010).

13. De Lame, C., Claeys, J-M., Greenwood, P., and Lagnemo, H., “Nanotechnology,” PPCJ (Jan. 2013).

14. Lucero-Álvares, J., Martin-Domínguez, I.R., Rubín-Zacarías, F., Ledezma-Gallegos, A., and Alarcón-Herrera, M.T., “Experimental Comparison of Heat Flow Through Concrete Roofing Flagstone with Different Coatings,” ISES Solar World Congress (2011).

15. Bierwagen, G., Fishman, R., Storsved, T., and Johnason, J., “Recent Studies of Particle Packing in Organic Coatings,” Prog. Org. Coat., 35, 1-9 (1999).

16. Khorassani, M., Pourmahdian, S., Afsar-Taromi, F., and Nourhani, A., “Estimation of Critical Pigment Volume Concentration in Latex Paint Systems Using Gas Permeation,” Iranian Polym. J., 14 (11) 100-1007 (2005).

17. Zosel, A., “Mechanical Behavior of Coating Films,” Prog. Org. Coat., 8, 47-79 (1980).

*Expancel and Levasil are registered trademarks of Akzo Nobel Pulp and Performance Chemicals AB in a number of territories worldwide.

Presented at the American Coatings Conference, April 9–11, 2018, in Indianapolis, IN.

CoatingsTech | Vol. 16. No. 1 | January 2019