By , , and Evonik Corporation, USA

In the higher pigment volume concentration (PVC) systems, the use of siloxane additives will be shown to improve stain-resistance and scuff-resistance properties, as well as positively impact other difficult to achieve end-coating properties.

Siloxane-based additives are broadly used in the coatings industry to provide a variety of performance benefits. As the industry continues to move toward lower volatile organic content (VOC) or near-zero VOC, there is renewed and continued interest in siloxane-based additives due to the efficiency of its many chemistries.

Because siloxane-based additives exhibit diverse end properties in coatings, a range of siloxane-based surface control additives generated through structure modifications can be used as highly effective additives in coatings. Utilization of these siloxane surface control agents in coatings significantly lowers surface tension, improving wetting of substrates, while avoiding the environmental implications of other chemistries that are traditionally used in this space.

In this article, we will demonstrate the use of siloxane additives as a means of improving early block resistance. In the higher pigment volume concentration (PVC) systems, the use of siloxane additives will be shown to improve stain-resistance and scuff-resistance properties, as well as positively impact other difficult to achieve end-coating properties.

Introduction

Siloxane-based chemistry presents a route to surface control that can enable a broad range of coatings with varied properties. This range of coating attributes can be attained through chemical modification of siloxane-based molecules that can differ in general structure, molecular weight, size of the siloxane domains, and the relative amount of siloxane in the molecule; additionally, the nature of the organo-modification plays a dramatic role in the behavior of the resulting siloxane polymer.1

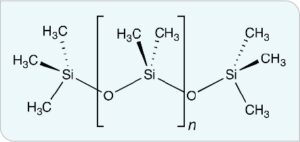

In Figure 1, the structure of an unmodified polydimethylsiloxane (PDMS) molecule is shown. To understand how a range of end attributes can be generated based upon a range of structural modifications to this “parent” polydimethylsiloxane molecule, it is important to recognize that the basic siloxane molecular structure, with silicon-oxygen backbone linkages and repeating units, can occur as fully methylated as shown in this figure. In this unmodified state, the siloxane molecule is quite flexible as well as both hydrophobic and oleophobic in nature, and its surface energy measures approximately 20 mN/m.2-4

FIGURE 1. Chemical structure of polydimethylsiloxane.

Because polysiloxanes can be synthesized to have varied molecular weights with shorter or longer siloxane blocks, it is possible to tune them for a particular end use. Siloxane-based wetting agents typically have short siloxane backbones that are modified with hydrophilic pendant groups to increase their water solubility, while longer chained silicone polyether structures with pendant groups or modified end groups can be designed for applications such as defoamers or deaerators. In each scenario, the organic modifications can impact the hydrophilic versus hydrophobic nature of the molecule. For instance, the presence of ethoxylated pendant or end groups will increase the molecule’s hydrophilicity while a high degree of propoxylation typically results in a more hydrophobic siloxane.1Polyether-modified siloxanes with larger siloxane blocks tend to be more hydrophobic and oleophobic, and this increases their surface activity in waterborne coatings; therefore, both 100% active liquid polyether-modified siloxanes and emulsions of higher molecular weight and crosslinked polyether-modified siloxanes have been used to modify the surface activity of waterborne coatings. Historically, these types of molecules have been used to improve surface slip, flow, and leveling,5 but, more recently, siloxane surface control agents have also been shown to significantly improve scratch and block resistance of wood coatings.1These findings prompted us to further explore the use of polyether-modified siloxanes in architectural coatings where we have now discovered that early block resistance, as well as stain and scuff resistance, can be improved by using emulsions of polyether-modified siloxanes and 100% active polyether-modified siloxanes. In some cases, use of polyether-modified siloxanes intended for extreme hydrophobing6 effect have been found to provide particular benefit.

Results and Discussion

Experimental

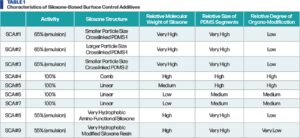

The siloxane-based surface control additives (SCAs) used in this study were commercial products sold by Evonik Corporation under the TEGO® Glide and TEGO® Phobe brand names, and they were used as received. General characteristics of the SCAs are shown in Table 1.

Continue reading in the January-February 2024 digital issue of CoatingsTech.