Microplastic pollution has jarred social consciousness, especially through a poignant look at its effect on ocean environments and marine life. Too many fish, dolphins, manatees, whales, birds, and shellfish are starved to death because their stomachs are filled with tiny indigestible plastic particles. Much of the world’s eco-marine activism has mobilized to fix this devastating problem. But the problem does not start and end in our oceans.

Unbeknownst to many, microplastics do not originate solely in the ocean. In fact, most microplastic accumulation primarily occurs on land and then moves to the waterways. Oceans have been polluted between 83,000 to 236,000 tons of microplastics yearly. Agricultural soils of all kinds, including agricultural soils, have 107,000 to 730,000 tons of microplastics dumped into the soil each year through processed sewage, mulches, slow-release fertilizers, and even seed coatings.1

During the last few years, there have been ongoing discussions about what defines a microplastic. Microplastics are plastic particles ranging in size from 5 mm to 1 nm. Primary microplastics are intentionally manufactured in smaller sizes for use in consumer cosmetics and biomedical products. Secondary microplastics are plastic waste particles that break down from larger plastic materials. Secondary microplastics brought about by degradation of larger discarded plastics are the subject of this article.

Only 1% of total microplastics are due to seed coatings.2 However, with a rather forceful kick from the European Chemicals Agency (ECHA), seed manufacturers are being required to eliminate microplastics that are generated due to seed coatings by October 2028. The rest of the world is not far behind. In fact, France has pulled implementation ahead to January 1, 2027. California has already proposed legislation that would eliminate 75% of plastic waste by 2030. While this does not yet affect seed coatings, history suggests that a broader set of regulations will germinate from this legislation.

Certain seed coatings are exempt from the October 2028 regulation:3

• Liquids: Must not form films upon drying.

• Natural origin coatings: No chemical modifications allowed. Even the simplest chemical modification might cause eventual microplastic formation. Commercially used natural polymers can contain additives, processing aids, or impurities that could hinder biodegradation or contribute to microplastic pollution.

• Water soluble coatings: Must have a solubility of ≤ 2 g/l.

• Biodegradable: Not to be confused with compostable materials.

• Coatings with no carbon atoms in the molecular chain structure

Manufacturers have embraced the challenge of eliminating microplastics from seed coatings. Even though seed coatings are 1% of the problem, producers across the globe are determined to become ZERO percent contributors to microplastic pollution.

The first step has been to make the microplastic coating fragments that detach from seeds as biodegradable as possible. Degradation rates vary, and no standard has yet been set. The lowest degradation rate so far is ≤ 48 days obtained from some commercially available polymeric coating mixtures. Biodegradable plastic formulations degraded completely in 32 days. Coatings selectively doped with certain plant growth promoting bacterium (Bacillus subtilis) degraded in ≤24 days.4 A good start, but still not enough.

A Seed Coating Primer

The first question in eliminating a problem material is to determine whether the material is really needed. Seed coatings are critically important for:

• Promoting germination and robust growth

• Providing resistance to pests and fungal infections

• Improving drought tolerance through osmopriming5 (for germination in low-moisture soils)

• Facilitating mechanical planting

• Increasing overall yield

While there are significant advantages for coated seeds (higher germination percentage, healthier roots and shoots as well as stronger established plants), there are also disadvantages (limited shelf life of treated seed, pesticide breakdown, incomplete crop protection, and surplus cannot be repurposed for grain). However, when weighing the risks, the ability to feed the world trumps any disadvantage. Eliminating seed coatings is not practical, so improvements to guard against microplastic formation and pollution must be the conclusion.

There are three basic methods of seed protection: film coating, encrustation, and seed pelleting.6

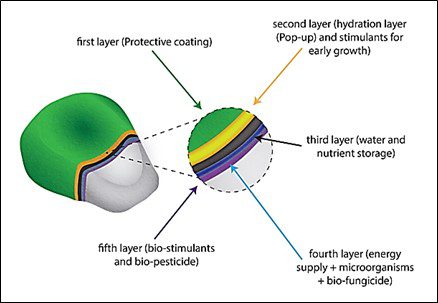

Film coating involves applying thin layers of coating solution (a total of less than 10% seed weight) onto the seed surface (Figure 1). For precise control over thickness and composition, a rotating drum or fluidized bed apparatus is used. Film coating allows the seed to maintain the original size and shape. In addition to resistance to environmental stressors, these seeds are well suited for mechanical planting and precision field applications.

FIGURE 1. Schematic of various protective film coating layers applied to seeds.7

Seed encrusting forms a protective matrix around seeds that is 100–500% seed weight. This allows for targeted delivery and sustained release of active ingredients throughout germination and early growth for pest and disease resistance, even in adverse soil conditions. A film is not formed. Many organic farmers take advantage of seeds treated with this technique.

Pelleting agglomerates seeds into uniform spherical pellets by coating them with a mixture of binding agents and additives that is >500% seed weight. This technique is especially good for small seed crops and precision planting. The enhanced seed-to-soil contact leads to good moisture retention, better germination rates, and uniform stand establishment.

Commercial Seed Film Coating Materials

Traditional seed film coatings are manufactured from polyethylene glycol (PEG), polyvinyl alcohol (PVOH) or chitosan (a glucosamine polymer).

Polyethylene Glycol is effective for improving seed germination and seedling establishment of sorghum under adverse moisture conditions. Osmopriming strengthens the antioxidant system further by increasing the osmotic adjustment of the seed resulting in increased stress tolerance.8

Lignan-modified PEG has a high molecular weight, takes a little longer to dissolve, and is less easily converted into water. The high-viscosity solutions do not transport oxygen, leading to no absorption by the seed, eliminating genetic or physical damage. Coating with 5-lignin PEG improved the germination percentage of maize seeds from 86.6% to 93.3%.9

Polyvinyl alcohol seed film coatings are extremely useful because water solubility and mechanical strength can be controlled. These coatings are used as a binder for adhering layers to the seed surface. Seed physical properties are improved and the delivery of active ingredients can be controlled. PVOH coatings decrease dusting and improve germination.10

Chitosan is one of the truly natural seed treatments and growth enhancers. This glucosamine polymer is developed from a sugar that comes from the outer skeleton of shellfish like crab, lobster, and shrimp. The material bonds to seeds via hydrophobic or cation-π interaction. Chitosan is a cationic source in an aqueous solution. Free amine groups form crosslinked polymer networks with dicarboxylic acids to improve mechanical properties.11

Unlike other polymeric materials used for film seed coatings, Chitosan influences the biochemistry and molecular biology of the plant cell. The targeted plasma membrane and nuclear chromatin causes changes in cell membranes, chromatin, DNA, calcium, MAP kinase, oxidative burst, reactive oxygen species, cellulose pathogenesis-related genes, and phytoalexins. It is an ecofriendly biopesticide that boosts the innate ability of plants to fight fungal infections.12 In addition, it allows for an innate immunity response in developing roots that destroys parasitic cyst nematodes without harming beneficial nematodes and organisms.

The Future

Sometimes the additives used in current seed coating formulations can lead to microplastic free products. Acting as rheology modifiers, film formers, and stabilizers, these biodegradable materials help to create porous films and coatings, enabling early seed germination.

One example is a microfibrillated cellulose viscous material that under high shear can be sprayed onto seeds. Under high shear, the fibrils break apart, lowering viscosity and allowing for consistent coating. After application, when high-shear conditions are removed, the fibrils reconnect forming solid films while still allowing for complete drying of the coating. These additives assist with germination, reducing or eliminating seed dusting and enabling longer shelf-life stability of liquid formulations.13

Seed coatings themselves are undergoing a metamorphosis as well. Petroleum-based polymers cannot always be made biodegradable and, at the same time, fully functional. The ideal would be to develop completely natural coatings that leave no residue, disappear without a trace, and retain critical seed protection and nutrient properties. Supramolecular engineered proteins have been developed over the past 15 years. They perform as well as synthetic polymer-based coatings but decompose naturally. This serves two purposes: mitigating soil degradation and eliminating microplastic pollution in farm fields.14

Thinking even further outside the box, these supramolecular engineered proteins might be the foundation for producing plant-based protein products to replace traditional single-use and even multiple-use carbon-chain plastics without the threat of microplastic pollution.

References

1. Petersen, K. S. There is an Alarming Amount of Microplastics in Farm Soil–and Our Food Supply. Environmental Health News. January 27, 2021.

2. Nielson, A.. The Seed Sector’s Battle Against Microplastics. Seed World. April 29, 2024

3. Verney, C.; DeGassert, G. Microplastic Seet Coatings the Perform Better than Conventional Ones: Myth or Reality? Agropages AgNews. June 14, 2024.

4. Accinelli, C. et al. Degradation of Microplastic Seed Film-Coating Fragments in Soil. Chemosphere. V 226. July 29, 2019. Pages 645-650.

5. Harish, D., et al. Effect of hydropriming and Osmopriming on the Germination of Seedling Vigor in East Indian Sandalwood (Santalum album L.). Forests. V 14, P. 1076. 2023.

6. Sharma, S. Enhanced Crop Potential: Exploring Seed Coating Techniques and Applications. LinkedIn. May 14, 2024.

7. King Quenson Group. A Farmer Friendly Technique for Producing Crops. King Quenson News. September 3, 2023.

8. Zang, Fei, et al. Seed Priming with PEG Induces Physiological Changes in Sorghum Seedling Under Suboptimal Soil Moisture Environments. National Institute of Health. October 15, 2015.

9. Yahong, G., et al. Preparation of Lignin Polyethylene Glycol Film-Forming Agent and Its Application in Chlorantraniliprole 5% Flowable Concentrate for Seed Coating. Industrial Crops and Products. V. 182. P 114877. August 2022.

10. Agriculture | Coating for Seeds, Fertilizers & FilmsPolyvinyl Alcohol. https://www.kuraray-poval.com/applications/agriculture (accessed September 10, 2024).

11. Chitosan. https://en.wikipedia.org/wiki/Chitosan (accessed September 10, 2024).

12. Hadwiger, L. A. Multiple Effects of Chitosan on Plant Systems: Solid Science or Hype. Plant Science. V. 208, 42-49. July 2013.

13. Electrolyte Tolerant Film Forming Agent for Seed Coatings. Borregaard https://www.borregaard.com/markets/agriculture/applications/seed-coating/products/film-forming-agent/ (accessed September 10, 2024).

14. Natural Alternatives to Microplastics Developed for the Seed Coating Industry. Environment Times. February 1, 2022. https://www.environmenttimes.co.uk/news/item/995-natural-alternatives-to-microplastics-developed-for-seed-coating-industry (accessed September 10, 2024).