By Anne Koller and Pol Storme, The Dow Chemical Company

One of the needs of the decorative paints market is the achievement of maximum hiding—the opacity that the end user perceives—with a minimum of paint coats. There are several tools designed to maximize hiding, such as the use of polymeric opacifiers* and pre-composite polymers,† which adsorb onto titanium dioxide (TiO2) to optimize its efficiency.

Hydrophobically modified ethoxylate urethanes (HEURS) and hydrophobically modified alkali swellable emulsions (HASE) rheology modifiers have also been developed to improve flow and leveling and therefore improve applied hiding. These rheology modifiers are efficient from low to high shear rate viscosity.

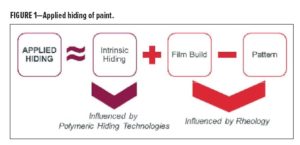

The applied hiding of a paint is represented by the equation in Figure 1. It is the sum of intrinsic opacity brought by the level of TiO2 and the polymeric technologies plus the paint thickness that is controlled by rheology. To this equation, one must subtract the negative effect due to lack of leveling, which creates low spots in the dry paint film, leading to low opacity.

Newly developed rheology modifiers** were designed to maximize paint leveling and surface smoothness and improve applied hiding.

*Ropaque™ technology, developed by The Dow Chemical Company.

†Evoque™ technology, developed by The Dow Chemical Company.

**Acrysol™ rheology modifiers developed by The Dow Chemical Company.

Presented at PaintIstanbul & TurkCoat 2016, March 24-26, 2016, at Istanbul Expo Center, Istanbul, Turkey.

Intrinsic Hiding

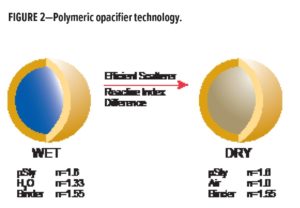

Intrinsic hiding in a paint is determined by the level of TiO2, the paint porosity, and polymeric technologies such as polymeric opacifiers and pre-composite technology. For the polymeric opacifier technology, the light scattering and hiding come from the difference of refractive index between encapsulated air in the dry stage and the surrounding components of the paint (Figure 2).

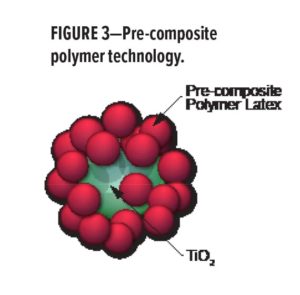

Another polymeric technology for intrinsic hiding improvement is pre-composite polymers, which are film-forming polymers used as binders. There are several available chemistries, including pure acrylic, styrene acrylic, and vinyl acrylic. Their polymer particles adsorb at the surface of TiO2 particles, as shown in Figure 3.

Another polymeric technology for intrinsic hiding improvement is pre-composite polymers, which are film-forming polymers used as binders. There are several available chemistries, including pure acrylic, styrene acrylic, and vinyl acrylic. Their polymer particles adsorb at the surface of TiO2 particles, as shown in Figure 3.

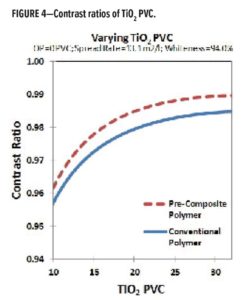

This adsorption prevents the TiO2 particle from crowding and therefore leads to improved light scattering and hiding. Figure 4 shows that when TiO2 PVC of a paint increases, contrast ratio values for the pre-composite polymer paints are higher than for standard paints developed without these polymers.

Film Build and Paint Pattern

Technologies to Analyze Paint Film Surface Smoothness

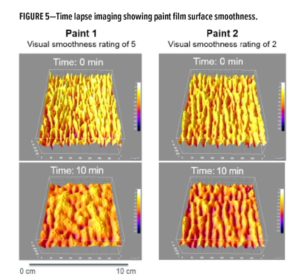

Now under study is the influence of the second part of the equation described in Figure 1 (i.e., the influence of rheology on applied hiding). To link applied hiding to the paint surface smoothness, pictures were taken of its surface as a function of paint-drying time. A light box in which the paint film was freshly applied by roller was lit from behind, and pictures were taken during drying.

Figure 5 shows the diversity of roller pattern obtained. On the left side of the figure (Paint 1), paint film is leveling well during the 0–10 min time lapse. On the right side, however, Paint 2 is not as leveled and shows more pronounced hills and valleys.

Those two same paints were analyzed by profilometry after the paint films dried. The roughness of the paint film was recorded, as shown in Figure 6. The top part of the figure shows a more uniform film surface after 10 min drying, with improved appearance and applied hiding. The bottom section of the figure shows a paint film with a rougher surface, displaying more low paint spots and leading to decreased applied hiding.

New Rheology Modifiers for Improved Applied Hiding

New low-VOC HEUR and HASE rheology modifiers for low- and mid-shear viscosity (Brookfield and Krebs Stormer types) have been developed. These are designed to offer the right balance between leveling and sagging resistance, yielding to high applied opacity.

Some of these new rheology modifiers use the Dow “Acid Suppression™” technology, and those rheology modifiers are supplied at low pH. At low pH, the hydrophobic end groups are tertiary amines which do not associate, leading to easy to use, low viscosity rheology modifier solutions. When used in a paint where pH is generally high (>8), hydrophobic groups will be able to associate and fill their thickening role.

Example A: Low-Shear Viscosity Builder HEUR Rheology Modifier*

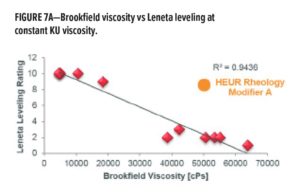

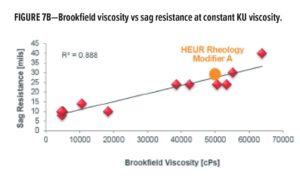

A newly developed low-shear viscosity builder, HEUR Rheology Modifier, which utilizes the Acid Suppression technology, is intended to offer better paint film leveling at the same sagging resistance as existing technologies. Figure 7A shows that this product offers better paint film leveling than a conventional commercial rheology modifier at the same low-shear paint viscosity adjusted at 10000 cps. This improved leveling characteristic is coupled with the same sagging resistance as conventional HEURS, as shown in Figure 7B.

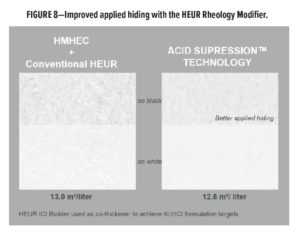

A semi-gloss paint formulated at 30% PVC, containing a hydrophobically modified HEC (HMHEC) and standard HEUR is reformulated with HEUR Rheology Modifier at the same rheology. Figure 8 shows a visual comparison of the two paints applied with a roller. The paint formulated with the newly developed material has better leveling characteristics and better applied hiding.

Example B: New Mid-Shear Builder HASE Rheology Modifier† for Partial Replacement of Cellulosic Thickeners

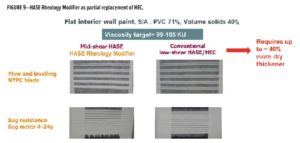

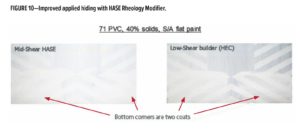

Styrene acrylic paints were prepared at PVC 71%. Paints were applied with a leveling blade on normalized charts. Figure 9 shows that at higher paint thickness, the HASE Rheology Modifier provides better paint leveling than a paint prepared with a mixture of HEC and low-shear HASE.

Figure 9 also shows that to control sagging resistance, it is recommended to combine the HASE Rheology Modifier with a low-shear HASE thickener or HEC.

To assess applied opacity, paints were applied with a brush. Figure 10 shows that paint containing the HASE Rheology Modifier has better leveling than paint prepared with cellulosic thickener after both one and two coats. The visual result is better applied opacity for the paint containing the HASE Rheology Modifier.

Conclusion

In this article, the available technologies to improve paint film applied hiding are detailed. Intrinsic opacity depends on TiO2 PVC and film porosity. Polymeric technologies such as organic opacifiers (Ropaque) and adsorbing polymers (Evoque) reducing TiO2 crowding are available to the paint formulator to improve intrinsic hiding.

For the end user, what counts is visual opacity, which also depends on paint film rheology and its ability to level without sagging to minimize low paint spots. Newly developed rheology modifier technologies maximize paint film leveling and surface smoothness, leading to better applied opacity.

Acknowledgments

The authors thank Dow scientists Inge De Preter (Dow Belgium), as well as Tara Conley, David Fasano, James Maher, John Rabasco, and Mark Langille (Dow USA), for their contributions.

CoatingsTech | Vol. 14, No. 5, May 2017