Food processing plants that produce ready-to-eat (RTE) foods, particularly meats, cheeses, and other products that require refrigeration, unfortunately provide ideal conditions for microbiological contamination. Listeria monocytogenes, for example, is commonly found in pasteurized milk, soft cheeses, ice cream, raw vegetables, fermented raw-meat sausages, raw and cooked poultry, and deli meats. One of the keys to prevention of bacterial contamination is the maintenance of smooth surfaces throughout the plant, including walls, ceilings, floors, and food preparation surfaces, which are easy to clean and sanitize. There have been numerous food recalls due to Listeria contamination, and this has attracted attention to the issues of plant sanitation, design, and construction. As one possible solution, VersaFlex, a supplier of high performance polyurea coatings, liners, and joint sealants, has developed a polyurea system specifically designed to provide desirable surfaces, even in aging plants with angled construction.

The largest Listeria outbreak in the United States occurred in 2011 and was traced to contaminated cantaloupes; 146 people across 28 states became ill, 142 of which were hospitalized, and 33 died. Hispanic-style cheeses sold by Roos Foods were recalled after a Listeria outbreak was traced to the company’s products early in 2014. Another cheese—Crave Brothers Farmstead Cheese—was a source of a Listeria outbreak in 2013. Apples were a recent source of contamination at Bidart Bros. apple processing plant near Bakersfield, CA (January 2015) and Appeeling Fruit Inc. of Dauberville, PA (September 2015). Also in the same month, the Maryland Department of Health and Mental Hygiene revealed that numerous products produced by Picnic Gourmet Spreads may have been contaminated. On April 20, 2015, Blue Bell Creameries voluntarily recalled all of its products on the market made at all of its facilities, including ice cream, frozen yogurt, sherbet, and frozen snacks, due to potential contamination from Listeria. According to information posted on the Centers for Disease Control (CDC) website, 10 people with Listeriosis related to this outbreak were confirmed from four states, with three deaths reported.

Listeria are gram-positive bacteria that grow under anaerobic and aerobic conditions and can, unlike most bacteria, multiply at refrigerator temperatures and withstand freezing. They are also widespread in the environment, including in soil and water, the manure of many animal species, and the feces of healthy human adults. In humans, Listeria infections can be serious to fatal for the elderly, the very young, and people with weakened immune symptoms, but typically do not cause healthy adults great harm. Humans are infected with Listeria only via ingestion, and typically through the consumption of contaminated food or water. Second only to Salmonella in the number of cases of illness in the United States due to foodborne contaminants, it is no surprise that L. monocytogenes is considered a significant public health concern. In fact, the U.S. Department of Agriculture has declared the bacterium an adulterant in RTE meats and adopted a zero-tolerance policy for its presence in these products.

Pasteurization can be used to kill Listeria, but in larger packages of RTE foods, the desired temperature is not always reached throughout the product, allowing some bacteria to persist. In addition, after pasteurization, some foods are mixed with unpasteurized ingredients that can introduce contamination. Equipment, countertops, and any other surfaces that come in contact with the food (gloves, etc.) can also be sources of contamination if not properly cleaned and sanitized. That can be challenging to accomplish in older processing plants that have walls and ceilings constructed with angled steel, i-beams, concrete block, interlocking metal and fiberglass panels, double-t ceilings, and tiles with concrete grout, which serve as excellent places for standing water and the build-up of dust, dirt, mold, and bacteria, including Listeria, Escherichia Coli, and Salmonella. Often the cracks, pits, and seams present in these plants provide surfaces for bacterial growth despite the use of aggressive power washing and chemical sanitation techniques. In addition, Listeria not only continues to grow at low temperatures, it can aerosolize and attach to equipment and people, and is therefore difficult to control in the processing environment.

It should also be noted that in older plants, other sources of contaminants are of real concern, such as chipping paint and spalled and cracked concrete. The aggressive cleaning protocols used in food processing plants only hasten damage to coatings and other surfaces, thus leading to the need for frequent maintenance and repainting and or complete replacement. Not only is this approach labor-intensive and very costly, in some cases plant shutdowns are required, having a further negative impact on profitability.

Today, with access to advanced food-grade polyurea coatings from VersaFlex, Archdale, NC-based Fixxus Rehabilitation Systems has been able to achieve complete rehabilitation of the walls and ceilings in food processing plants, often during planned maintenance weekends. Using a patented process including structural rehabilitation, precise surface preparation, retrofit design modifications, and VersaFlex’s food-grade protective polyurea coatings, Fixxus delivers a monolithic liner that eliminates all existing chips, seams, and gaps, according to CEO Danny Cook. He also notes that as part of this process, the space is “reshaped” through so that only smooth, curved lines remain and areas where water, dirt, grime, and pathogens can accumulate are eliminated.

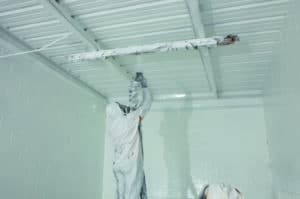

The fast-curing pure polyurea coating from VersaFlex, which is specifically formulated for use by Fixxus in food processing plants, is a key component of the rehabilitation system. Cook notes that the material is spray applied, which means it can be applied quickly by trained applicators, built up to any required thickness, and shaped into the modified wall and ceiling design. “Therefore, a one-coating system can be used to rapidly create a monolithic surface, minimizing plant downtime. Most other coatings take one to four days to cure, which is too long when you need to get the plant back on line. Polyurea sets up and can be returned to service within minutes,” he adds. A custom polyurea topcoat provides a very slick surface that resists standing water and prevents dust, dirt, and bacteria from taking hold. “VersaFlex worked closely with us to make adjustments on the polyurea cure time, gel time, and the topcoat properties to meet our specific needs for the food processing industry,” Cook observes.

With 15 to 20 workers, including a trained coating applicator, Fixxus can complete the rehabilitation of an entire food processing plant in two to four days. Cook notes that the entire workforce is fully trained in the details and standards for cleanliness and sanitizing in food processing, cleanroom, and pharmaceutical-grade facilities. The rehabilitation process starts with the repair of any areas with spalled or cracked concrete, chipping and peeling paint, or heavy corrosion. Intensive cleaning to remove grease and grime and other surface contaminants is then performed using specially approved wash-down solutions and self-contained high-powered water-blasting techniques. Holes, voids, seams, and penetrations are then filled and any reshaping is completed using, for example, a combination of concrete and molded foam materials to transition any flat surfaces from 90° to 45° to prevent standing water from accumulating. Every piece of equipment, pipe, flooring, and other exposed areas is then wrapped in plastic or covered before spraying of the polyurea coating, which is completed carefully and evenly in order to provide a nice, clean look, according to Cook.

“Often this approach—complete interior wall and ceiling rehabilitation—is the quickest and most cost-effective way for food processors with aging facilities to break the cycle of constant deterioration and ongoing repair while also minimizing the risk of pathogen-based product recalls,” Cook concludes.