Editor’s note: This online exclusive includes a roundtable Q&A with industry experts from Kraton, Dow Coating Materials, PPG’s Traffic Solutions, Arkema Coating Resins, and BASF.

By Leo Procopio, Paintology Coatings Research LLC

The United States has the most extensive road infrastructure in the world, with more than 4.1 million miles of public roads (of which about 2.8 million miles are paved.) From small rural roads to large urban highways, these roadways are heavily traveled, with about 3 trillion miles covered by vehicles annually.1 And with approximately 40,000 annual traffic deaths, traffic safety is always a high priority. Traffic safety professionals employ a variety of traffic control devices to make our roads as safe as possible, including signs, signals, and road markings. The Manual on Uniform Traffic Control Devices for Streets and Highways (MUTCD), issued by the Federal Highway Administration (FHWA), defines standards for the installation and maintenance of traffic signs, signals, and road markings on roads open to public traffic.2

Road markings are key elements of road surfaces and provide drivers with essential information to aid in navigation and make their journey safer. Key information such as lane demarcation, indication of passing zones, and the highlighting of safety awareness zones (e.g., schools, crosswalks, and bicycle lanes) is communicated to drivers via road markings. Paint and coating technology plays a significant role in the manufacture of road markings. The coating technologies are also utilized in adjacent applications such as pavement markings for parking lots and airfields.

Traffic paints and road markings are dominated by two technologies – waterborne paints and hot melt thermoplastics. The overall U.S. market for traffic paints was recently estimated to be approximately 10% by value of the Special Purpose Coatings segment for the year 2023, or about $710 million.3 Another study placed the value of the U.S. traffic paint market, excluding hot melt thermoplastics, at approximately 52 million gallons and $650 million for 2015.4

The market is large and growing, and raw material manufacturers and coatings suppliers are constantly innovating to meet the performance demands of the industry. This article will discuss some of the science behind road markings. A roundtable Q&A, in which we ask several experts for their thoughts on where the industry is today, trends, challenges, new developments, the role of sustainability, and what to expect in the future, appears here.

Types of road markings

Waterborne coatings based on acrylic latex polymers are the most common type of traffic paint used today. Prior to the 1990s, solventborne chlorinated rubber and alkyd coatings were very commonly used to paint road lines because of their fast dry times; however, due to VOC regulations, waterborne coatings now dominate. Acrylics generally have good weathering resistance and durability, as well as adhesion on the asphalt and concrete surfaces found on roadways. Advances made in the 1990s led to fast setting acrylic latex coatings with greatly enhanced dry times.5 Fast dry times are important when striping roads in order to minimize lane closure times, as well as to prevent the tracking of wet paint across the road surface if lines are run over by tires shortly after application.

When better film toughness and longer service life is desired, multi-component liquid coatings relying on highly crosslinked films can be utilized. Examples include two-component (2k) epoxies and polyureas that have excellent adhesion to the road surface and have better resistance to wear and abrasion.

Another high-solids solution for road markings are methyl methacrylate (MMA) coatings, also referred to as cold plastic. These 100% solids liquid coatings consist of acrylic monomers and oligomers which are mixed with a peroxide initiator just prior to application. After application to the road, a polymerization reaction rapidly occurs, resulting in a fully cured coating. These crosslinked coatings are less common than waterborne coatings due to their higher cost, but they can provide higher performance when needed.

In addition to waterborne acrylic traffic paints, another common road marking technology is hot melt thermoplastics. Thermoplastic road marking materials are 100% solids materials supplied in solid form and are typically based on a petroleum-based hydrocarbon resin or a rosin derivative along with optional plasticizers. The coatings are heated above their softening point, typically above 200°C, and applied by spray or extrusion to the road while hot. Once cooled, they solidify again, allowing the road to be returned to service quickly. Even though the low molecular weight resins don’t impart excellent wear resistance to the final coatings, thermoplastics are applied in thick layers (2 or 3 mm), which leads to long service life for this technology. Thermoplastic can also be pre-formed into designs such as letters or arrows, which can then be easily positioned on the road and melted in place with a torch.

Retroreflectivity and other key properties

As with any coating, traffic paints have a number of important properties that must be met to insure excellent performance in the field. To remain functional, lines and other markings must be visible to drivers. Film properties like adhesion and resistance to wear and abrasion (e.g., from tires or snowplows) are required to guarantee the line remains on the road surface. Color and contrast with the road surface also have an impact on visibility, especially during the daytime, and for this reason white and yellow are the favored colors.

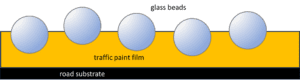

FIGURE 1. Traffic paint film with glass beads protruding from the surface.

Nighttime visibility, however, relies on the principle of retroreflectivity. To be easily seen at night, the road marking must reflect light from the headlights back to the driver. This is accomplished by incorporating retroreflective glass beads into the road marking. As an example, for liquid traffic paints, glass beads are dropped onto the wet paint immediately after paint application and become embedded into the final film (Figure 1).

For thermoplastic road markings, glass beads can be dropped on the film while still hot but can also be incorporated into the material before application. By incorporating the beads throughout the thermoplastic layer, retroreflectivity is maintained even as the film and beads on top are worn away, because new glass beads will become exposed at the surface.

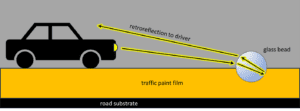

FIGURE 2. Depiction of retroreflection of light by glass beads embedded in traffic paint film.

Figure 2 shows the process of retroreflectivity for pavement markings. Light from the approaching headlight enters the glass bead, bends, reflects off the paint on the back of the bead, then bends again as it leaves the bead and is directed back to the driver. To function, the glass bead must be partially protruding from the film surface (about 50% is optimal.) Variables such as bead size, refractive index, and weight loading of beads in the film impact the amount of light returned to the driver.

Retroreflectivity can be measured in the laboratory or on installed traffic lines using portable instruments and according to standard methods for dry (ASTM E1710)6 or wet (ASTM E2177 and E2832)7,8 conditions. Retroreflectivity is reported in units of millicandelas per square meter per lux (mcd/m2/lux).

The MUCTD was updated in 2022 to require maintenance of retroreflectivity at a minimum of 100 mcd/m2/lux for longitudinal lines on dry roads with speed limits of 70 mph or higher, with compliance expected by 2026.9 It is more difficult, however, to maintain retroreflectivity under wet conditions, particularly if there is a layer of water covering the glass beads. Standard glass beads have a refractive index of 1.5, but don’t perform well when wet because the layer of water, which has a higher refractive index than air, bends the light at a different angle. This results in less light being returned to the driver and lower visibility of the line. Beads with larger diameters and higher refractive indexes have been developed for improved retroreflectivity under wet conditions.

How well a traffic paint retains retroreflectivity over time impacts its service life. Paint films will lose adhesion to glass beads due to tire abrasion and weathering, beads will be removed from the surface, and retroreflectivity will decrease. While retroreflectivity is one measure of how well a traffic paint is holding up, durability is also defined as film loss that exposes the road surface, and is evaluated according to ASTM D 913.10 Durability is affected by adhesion to the road surface, film toughness, and weathering and abrasion resistance. Poor durability leads to loss of color and visibility of the line even in daylight.

One other key property for traffic paints, particularly for liquid coatings such as waterborne acrylics, is dry time. Fast dry times are important to prevent tracking of paint if wet lines are run over by tires, as well as the possibility of wash-out if a rain cloud happens to pass over a freshly painted line. In addition, faster dry times allow less downtime for traffic lanes. In the laboratory, dry time can be evaluated according to ASTM D711, which utilizes a weighted wheel with rubber O-rings.11 Simulating the pressure of a tire on pavement, the wheel is rolled over the coating at various times to determine the drying time needed for no pick-up.

Alternatively, a real-world evaluation can be done in the field according to ASTM D713, where an auto tire is driven over a freshly painted line at various dry times to determine the no-track time.12 Dry-to-no-pickup times do not necessarily indicate that the paint has wash-out resistance in case of a rain event. Dry-through indicates the point at which a waterborne paint film has enough integrity to resist rain and can be detected by applying a gloved thumb with light pressure and twisting without damage.

Formulating road markings

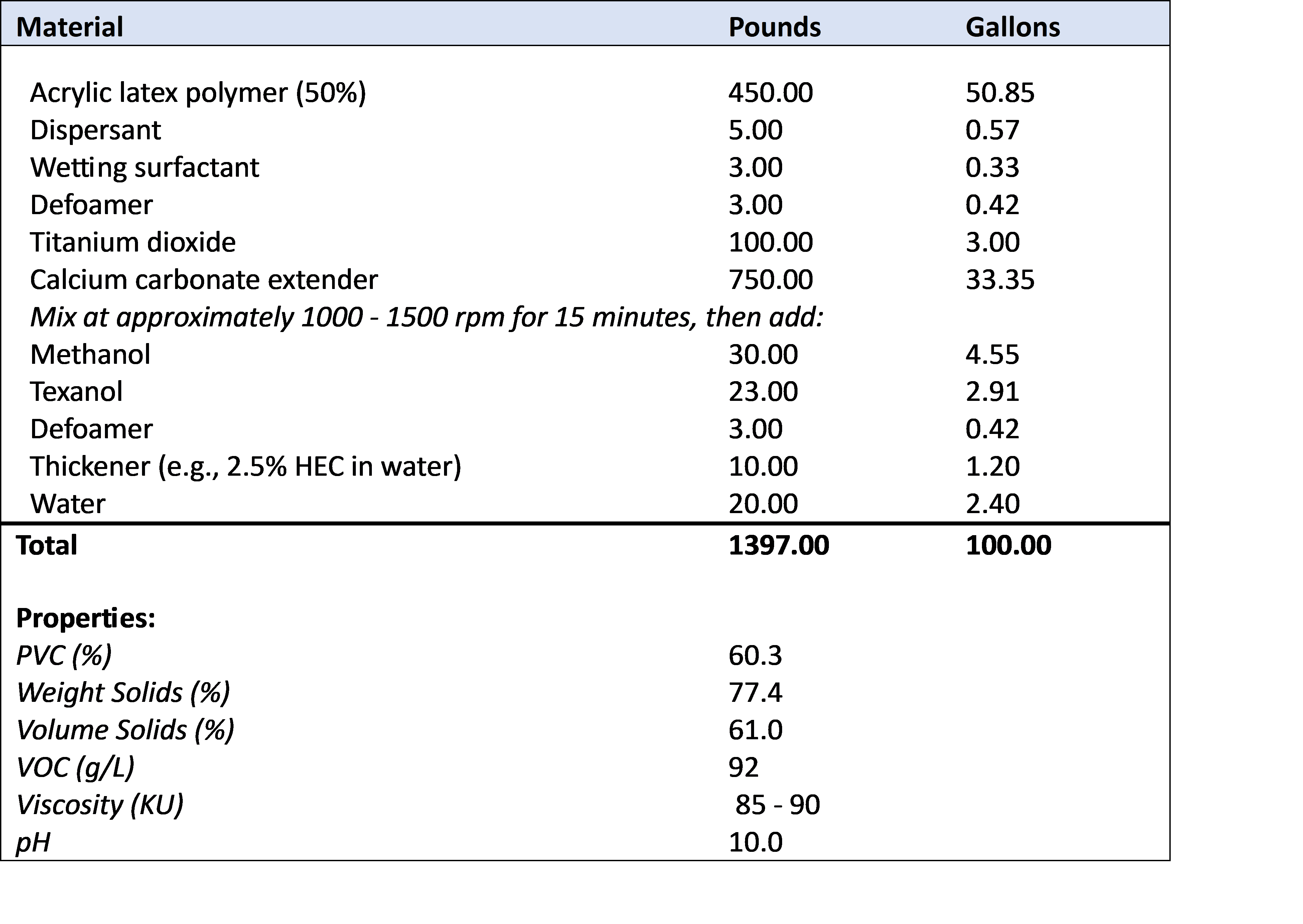

TABLE 1. Generic White Traffic Paint Formulation Based on a Waterborne Acrylic Latex

For waterborne traffic paints, one way to achieve fast dry times is to remove excess water from the formulation and formulate at high-volume solids. For this reason, waterborne traffic paints are formulated at high pigment volume concentrations (PVC) and using high levels of extenders. Most of the water in the final paint comes from the latex polymer. An example of a generic white traffic paint based on a waterborne acrylic latex polymer is shown in Table 1.

Pigments are dispersed directly into the latex to minimize the amount of extra water. Calcium carbonate is often used as extender pigment due to its low cost, whiteness, and low oil absorption (i.e., easy dispersion at low water demand.) In addition to coalescent needed for film formation, the other main source of VOC in a waterborne traffic paint is from the use of an alcohol such as methanol to optimize freeze thaw resistance and dry-to-no pickup times.

Another way to achieve fast dry times in a waterborne traffic paint is to choose a polymer that utilizes quick-setting technology.5 The quick-set mechanism is triggered by a decrease in pH as ammonia leaves the drying paint film. The latex is therefore supplied at high pH (typically above pH 10.0), and the paint formulation is adjusted to maintain a high pH, otherwise poor stability can result in the can. A unique feature of this technology is faster dry-through times compared to conventional waterborne paints, even at higher humidities where water evaporation is slower.

FIGURE 3. Application of green bike lane based on waterborne DURATRACK™ technology. The green paint is first applied by multiple spray guns on the right, followed by application of the glass anti-skid aggregate on the left of the picture. Photograph courtesy of Dow.

For white paints, a minimum of 1 lb/gal of titanium dioxide is typically specified to ensure good opacity. Of course, other colors are available, such as yellow for centerlines or green for bike lanes, and may require a mix of inorganic and organic color pigments to achieve the correct shade. An example of a waterborne green bike lane coating being applied is shown in Figure 3. Because of the greater width of the bike lane compared to typical road marking lines, several spray heads are used to apply it in a single pass. A glass anti-skid aggregate is applied immediately after the paint is sprayed onto the road surface.

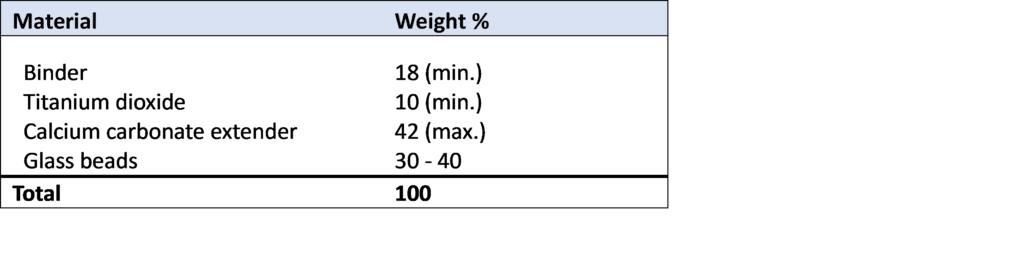

TABLE 2. Generic White Road-Marking Formulation Based on a Thermoplastic Resin

In addition to waterborne traffic paints, hot melt thermoplastic road markings are also commonly used on roads. An example of a generic white thermoplastic formulation is shown in Table 2.13 The final formulation is supplied as a solid, either in granular or brick form. Glass beads are mixed into the material during formulation (referred to as intermix), and additional beads could be also dropped onto the surface of the marking immediately after it is applied to the road. The binder is typically either a hydrocarbon resin or rosin derivative, and additionally plasticizers may be employed to prevent brittleness of the applied road marking.

The driving force behind traffic paint formulations are state departments of transportation (DOTs), who are key end-users and ensure paint quality and performance through specifications. Specifications often dictate the specific types and amounts of ingredients for the paint manufacturer to use,14 as well as expected performance properties.15

Testing Performance

State DOTs and municipal agencies are typical end-users of road markings and use qualified product lists (QPLs) to signal what products they have found acceptable for use on their roads. To be placed on a QPL, the road marking material will undergo testing to prove that it can provide satisfactory performance. Many traffic paints are evaluated through a testing program for pavement marking materials run by the American Association of State Highway and Transportation Officials (AASHTO).

Now known as the AASHTO Product Evaluation and Audit Solutions Program, it was formerly referred to as the National Transportation Product Evaluation Program (NTPEP).

FIGURE 4. Waterborne traffic paint being applied on concrete during a NTPEP transverse test deck application in Wisconsin. Photograph courtesy of BASF.

The AASHTO program involves real-world testing of pavement markings on test decks located across the country, with application of paints supervised by the host state DOT. Suppliers are afforded the opportunity to apply transverse lines (i.e., perpendicular to the flow of traffic) of their materials on asphalt and concrete test decks. Multiple lines of each material are applied. An example of waterborne traffic paints being applied on a test deck in Wisconsin is shown in Figure 4.

Transverse lines are a difficult test environment for road markings because they come into more direct contact with automobile tires compared to longitudinal lines such as edge and center lines. Properties such as color, durability, and retroreflectivity are periodically measured in both the wheel track area (the area where tires most commonly come into contact with the line) and skip area (near the edge line). DOTs and other end-users can use the information to make decisions on which products to use on their roads.

The data gathered from the annual test decks are stored online and can be accessed at the AASHTO Product Evaluation and Audit Solutions DataMine website.16 Data recorded include the environmental conditions during application, physical properties of the paints, the type and loading of glass beads, and wet film thickness (WFT) applied. Both laboratory test results and field performance are also recorded, including retroreflectivity, durability, and color readings out to three years exposure. In addition, photographs of the actual lines are also stored in the online system.

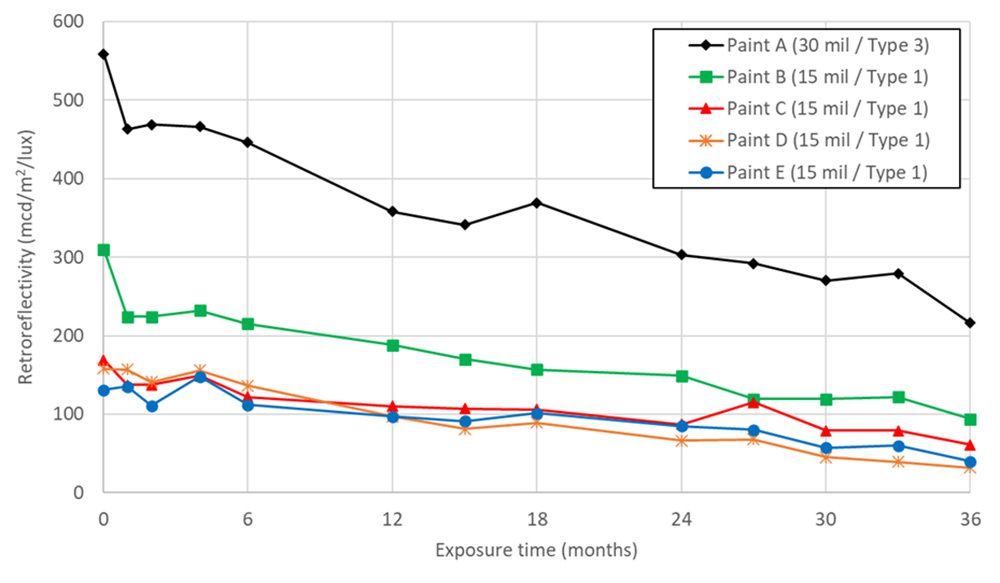

The test decks are valuable because they evaluate multiple products applied at the same time and to the same road surface, and which experience the same exposure conditions, allowing an “apples-to-apples” comparison of performance. An example of the type of data available is shown in Figure 5, which plots retroreflectivity under dry conditions for several waterborne white traffic paints applied to a test deck in Florida in 2019. The road markings were followed for 3 years, with some obvious differentiation in performance. Paint A was observed to have much higher retroreflectivity compared to the other paints over the course of the evaluation. Possible reasons for this include that Paint A was applied at a higher film thickness (30 versus 15 mils WFT), and with a larger grade of glass bead (Type 3 versus Type 1, according to AASHTO M-247)17 compared to Paints B through E.

Figure 5. Retroreflectivity vs exposure time for waterborne paints exposed on an AASHTO NTPEP test deck in Florida starting in 2019. Note that Paint A was applied at a higher wet film thickness (30 vs 15 mil WFT) and with a different type of glass bead (Type 3 vs Type 1, according to the AASHTO M257 specification17) compared to the other paints. Data selected from the AASHTO Product Evaluation and Audit Solutions Datamine website for Pavement Marking Materials.

Conclusions

The first documented example of a painted traffic line in the United States is from 1911 in Wayne County, MI. In the more tha 100 years since that first use, the technology and science behind road markings has progressed tremendously. Today’s road markings are highy engineered materials designed for long life, excellent visibility even under adverse conditions, and cost-effectiveness. Our roads are safer because of road markings, and coatings technology has played an important role in getting us to where we are today.

Of course, that is not to imply there is nothing more to achieve for traffic paints. Higher levels of durability and better retention of retroreflectivity lead to longer service lives and are good goals, as is improving retroreflectivity and thus driver visibility under wet conditions. And the interaction between autonomous vehicles (AV) and road markings is an important topic being discussed within the traffic safety community and will be key to the success of AV technology. There is no doubt that coatings science will continue to have a key role in the future development of road markings.

References

- “Highway Statistics 2020”, Office of Highway Policy Information, Federal Highway Administration, U.S Department of Transportation, accessed at fhwa.dot.gov/policyinformation.

- “Manual on Uniform Traffic Control Devices for Streets and Highways,” Federal Highway Administration, U.S Department of Transportation, 2009.

- Pilcher, G., “The State of the U.S. Paint and Coatings Market: More Reliable Supply Chain, Slight Decline in Volume,” CoatingsTech, 20 (5), pp. 50 – 62, Sept/Oct 2023.

- “The U.S. Paint & Coatings Industry, 2015–2020”, Kusumgar, Nerfli & Growney, 2016.

- For example, see: Landy, F.; Mercurio, A.; Flynn, R., “Shelf stable fast cure aqueous coating,” US Patent 5,527,823.

- “Standard Test Method for Measurement of Retroreflective Pavement Marking Materials with CEN-Prescribed Geometry Using a Portable Retroreflectometer,” ASTM E1710, ASTM International, 2018.

- “Standard Test Method for Measuring the Coefficient of Retroreflected Luminance (RL) of Pavement Markings using the Bucket Method in a Condition of Wet Recovery,” ASTM E2177, ASTM International, 2020.

- “Standard Test Method for Measuring the Coefficient of Retroreflected Luminance of Pavement Markings in a Standard Condition of Continuous Wetting (RL-2),” ASTM E2832, ASTM International, 2017.

- “National Standards fro Traffic Control Devices; the Manual on Uniform Traffic Control Devices for Streets and Highways; Maintaining Pavement Marking Retroreflectivity,” Feederal Register, 87(150), p. 47921, 2022.

- “Standard Practice for Evaluating Degree of Traffic Paint Line Wear,” ASTM D913, ASTM International, 2020.

- “Standard Test Method for No-Pick-Up Time of Traffic Paint,” ASTM D711, ASTM International, 2020.

- “Standard Practice for Conducting Road Service Tests on Fluid Traffic Marking Materials,” ASTM D713, ASTM International, 2023.

- For example, see: “Standard Specification for White and Yellow Reflective Thermoplastic Striping Material (Solid Form),” Specification M 249-12 (2020), American Association of State and Highway Transportation Officials, 2020.

- For example, see: Texas Department of Transportation Specification DMS-8200, Traffic Paint, 2017.

- For example, see: Federal Specification TT-P-1952F, “Paint, Traffic and Airfield Marking, Waterborne,” 2015.

- The AASHTO Product Evaluation and Audit Solutions DataMine website for Pavement Marking. Materials can be accessed at https://data.ntpep.org/PMM/Products.

- “Standard Specification for Glass Beads used in Pavemet Markings,” Specification M 247-13 (2018), American Association of State and Highway Transportation Officials, 2018.

Leo J. Procopio, Ph.D., is president and owner of Paintology Coatings Research LLC. For more information, visit www.scienceofpaint.com or e-mail at leo.procopio@scienceofpaint.com.