By Simon Aben, Jörg Rüger, and Mark Coward, Clariant

Biocides, especially isothiazolinones, can often trigger allergic reactions, which, in recent years, has driven the demand for water-based biocide-free paints for interior and exterior areas, as well as regulation. Silicate paints are an alternative, as they use liquid glass (i.e., liquid potassium silicate), rather than biocides, as a mineral/inorganic binder to adjust the paint pH so that bacteria growth is inhibited. To support paints and coatings formulators in their binder decision-making, we investigate the influence of binder choice on the wet scrub resistance of organosilicate paint (a silicate paint with a binder modification of more than 5%, which shows good adhesion to a variety of substrates) under various storage conditions, comparing four vinyl acetate ethylene (VAE) binders against each other and against the performance of several styrene acrylate binders.

Silicate paints for architecture

There are three categories of silicate paints. First, those that do not have an organic component and that typically contain 10–30% potassium silicate; these are historically used in buildings for beauty and protection. Second, standard silicate paints that have less than 5% organic content and a similar level of potassium silicate. These can be used in interior and exterior applications and adhere to a wider range of substrates. Finally, there are organosilicate paints with a binder modification of more than 5% and a lower level of potassium silicate. To enable the handling and suitability of these mineral paints for a wide variety of applications, organic binders are added to the paints as a complement to the liquid glass. These can also be used indoors and outdoors and show good adhesion to a variety of substrates.

Binders for high-pH systems

A recognized disadvantage of biocide-free paints containing liquid glass is that, due to their rheological behavior, they can be difficult to formulate and apply using a paint roller or a brush application. Here, the choice of the binder is crucial. It should have a compatibility with liquid glass/resistance to high-pH conditions, otherwise stability issues and loss of performance such as a lower wet scrub resistance will most likely be observed.

While styrene acrylate binders are often used in organosilicate paints, the performance of other types of binders, such as vinyl acetate ethylene (VAE) binders, is often discussed in the industry since these tend to saponify due to the high-pH conditions.

To better understand this effect, in the following study we investigate the performance of four VAE binders with different chemistries and physical properties. As well as comparing the performance between the four VAE binders, within this study the performance of styrene acrylate binders in a similar organosilicate paint system is presented as a comparison to VAE binders.

We chose wet scrub resistance as a parameter for the study because a significant increase in coating layer thickness loss after wet scrubbing is a clear indicator demonstrating that a binder has saponified. Wet scrub resistance is also a highly valued paint feature serving as a major selection criterion for interior paints for the DIY customer.

Results at a glance

The use of VAE and styrene acrylate binders for silicate-based paint systems has been proven feasible. Both binder types show major differences in quality with regard to wet scrub resistance. Good performance can be achieved with selected raw materials in biocide-free organosilicate paint systems.

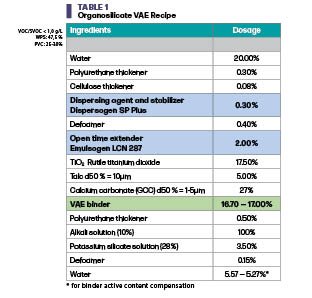

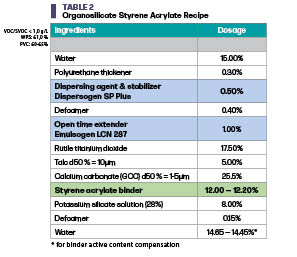

The following recipes were used to prepare the organosilicate paints containing the VAE binders (Table 1) and the styrene acrylate binders (Table 2). The paints were prepared using a Dispermat CN 10 dissolver from VMA Getzmann company.

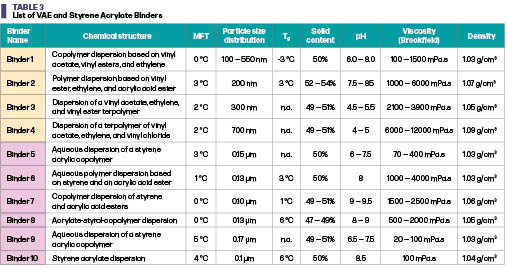

All the binders used in this study are commercial binders and their physical and chemical properties are listed in the following tables. To make Table 3 easier to review, the VAE binders (Binders 1-4) are highlighted in yellow and the styrene acrylate binders (Binders 5-10) are highlighted in pink.

Testing at different conditions

All the formulations and tests described below in the frame of this study were carried out by the same person on the same equipment, raw materials and consumables, to limit the influence of external factors on the results. In order to study the effect of the storage condition on the performance of the binder, all the paints were split and stored at various temperatures: room temperature 25° C, 40° C, and 50° C. Samples were then taken out of each of the stored paints at different storage times in order to perform wet scrub resistance tests, according to ISO DIN EN 13300. Wet scrub resistance tests were performed with PVC cards (following DIN 53778) and an abrasion and scrub resistance tester (Erichsen washability and scrub tester model 494) while using 2,5g/L Hostapur SAS 60 (Clariant) as a washing solution.

Continue reading in the November-December 2023 digital issue of CoatingsTech.