By Victoria Scarborough, Ph.D., The ChemQuest Group

My recent keynote presentation on megatrends given at the Paintistanbul Turkcoat Congress generated significant interest in electric vehicles (EV) as a driver for coating innovations. Given that every major automobile manufacturer has announced plans for conversion to electric vehicles in the next decade and global sales of new EVs are rising significantly, it is no surprise this market represents new opportunities for growth.

While the net number of cars being sold may stay relatively constant, the coating types per vehicle will grow based on the increased number of EV components per unit that require coatings. For example, there are at least 100 more electronic control units per EV than found in gas-powered cars.

While the net number of cars being sold may stay relatively constant, the coating types per vehicle will grow based on the increased number of EV components per unit that require coatings. For example, there are at least 100 more electronic control units per EV than found in gas-powered cars.

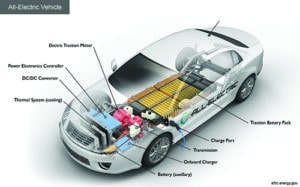

While each model may look different, the overall design of an EV has three basic areas where coatings are useful:

- Battery packs

- Power conversion components

- Electric drive systems

Each manufacturer has its own battery pack design, with a unique set of needs and challenges. Regardless of the construction of the pack, they all need fire protection, corrosion and impact protection, temperature management and electrical shielding.

Temperature control is essential to maintaining battery efficiency and durability over time. Innovative thermal management coatings can provide a partial solution by helping to control temperatures, whether they are too hot or too cold.

Battery packs also require protection from electromagnetic interference. Coatings with dielectric properties can help prevent arcing between metal parts. Intumescent coatings may protect from fire damage if batteries fail, overload and start a fire. The battery pack environment contains polyelectolytes that requires coatings that resist corrosion. EVs are also designed with hundreds of sensors, all of which need protection from wear. Clear protective coatings can be used but they cannot diminish signal tranfer.

In addition to the EV itself, developments in autonomous-

vehicle technology have demonstrated the need for road improvements, particularly in the requirement for consistent, easily visible pavement markings. If not properly marked, it is harder for an autonomous vehicle to know exactly where they are on the road. Here, coating manufacturers can play a role in providing traffic paints that can potentially communicate with the EV. Photonic pigments can be added to coatings to help provide guidance on road postion. Thus, smart traffic coatings can be formulated to help talk to the EV.

Autonomous vehicles are also programmed to read road signs. Similarly, coatings that contain NIR transparent or reflective functional pigments can deliver a signal response back to the EV and improve object recognition. Several pigment manufacturers already have products available for this purpose.

Obviously, the coatings industry has been serving the automotive market since the introduction of the Ford Model-T. Many traditional coatings used today can be used on electric vehicles. But EVs represent a major engineering pivot from mechanically driven to chemically driven vehicles. As climate change pushes further regulatory changes to reduce fossil fuels, electric vehicles will eventually dominate the market. This requires the coatings industry to respond quickly with new products and innovations to address the needs of electric vehicles and their vastly different architecture.