, , , , and BASF Corp. USA

Correlating paint film integrity in the lab with wood grain crack resistance in real-world exposure is a challenging task. In 2020, we reported on early correlations between adhesion and film mechanics that when combined could fit a grain cracking predictive model to outdoor weathering.¹ In this study, we sought to further challenge our own model by greatly expanding our study to include 79 more paints on various substrates. Our aim was to elucidate potential correlations between paint film mechanical properties and realworld exposure performance and to test the validity of our early model.

Through our analysis, we identified several significant factors and developed a statistical model. Although it is still in its early stages, this model shows promise in providing insights into the performance of paints under real-world exterior conditions. Further refinement and validation of this model could have significant implications for the paint industry. Such a model could enhance the durability and quality of wood coatings and accelerate the development timeline.

Introduction

The correlation between laboratory tests and real-world applications of paint is a critical area of research within the paint industry. While laboratory tests provide valuable insights into paint properties and performance in controlled environments, they often fail to accurately replicate the complex and dynamic conditions found in real-world environments.² Consequently, investigating the correlation between laboratory results and real-world scenarios, particularly concerning grain cracking in paint, becomes essential.

Grain cracking is a prevalent issue that occurs when paint applied to dimensionally unstable wood substrates undergoes cyclic stress from temperature fluctuations, moisture, and other environmental factors. However, reproducing these conditions accurately within a laboratory setting proves challenging, potentially leading to results that do not truly reflect the behavior of paint in the field. Understanding the correlation between laboratory tests and real-world applications of paint becomes critical in developing more accurate and reliable testing methods, as well as improving paint design and formulation. By studying this correlation, researchers and professionals in the paint industry can develop more effective strategies for preventing grain cracking and other forms of paint degradation. This, in turn, leads to enhanced durability, aesthetics, and overall quality of paint products. Therefore, investigating the relationship between laboratory tests and real-world applications is a vital endeavor that holds significant implications for the paint industry and its consumers.

In our previous study, we focused on evaluating the mechanical performance of 18 different paints.¹ The aim was to establish correlations between the performance of these paints and their real-world exposure results. To achieve this, we employed multiple linear regression (MLR) models. During the course of our research, we discovered that the results obtained from various laboratory and accelerated test methods were significantly confounded. These results did not yield easily decipherable trends.

To overcome these challenges, we expanded our study to include additional parameters. Specifically, we measured the tensile elongation at multiple conditions, adhesion to water-conditioned surfaces, and film hardness. By incorporating these factors, we were able to develop a predictive model that exhibited a high degree of accuracy. It is important to note, however, that this model is currently limited to the scope of a single commercial paint study.

To progress the development of highperformance exterior wood coatings, it is crucial to validate and expand on our findings. This entails conducting a similar study that encompasses a broader range of paints, covering a wider spectrum of mechanical performance. By doing so, we can further investigate and identify correlations between mechanical properties and real-world exposure results. This expanded research will ultimately serve to enhance the predictive model and transform it into a valuable tool for the development of high-performance exterior wood coatings.

In this study, we examined 79 paints with different formulations, colors, sheens, and significant variations in mechanical performance. These paints were applied to various substrates and evaluated every six months to determine if we could establish a correlation between accelerated testing and long-term real-world exposure results. This comprehensive analysis aims to provide a more robust understanding of the correlation between laboratory tests and real-world applications of paint, ultimately contributing to the advancement of paint technology and the development of superior paint products.

Experimental Setup

Paints

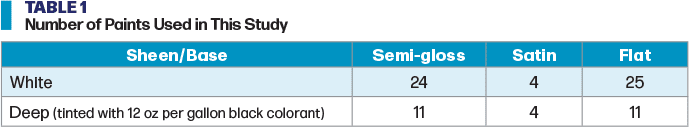

In this study, the 79 paints used included 16 experimental waterborne acrylic architecture paints and 63 commercial waterborne architecture paints purchased from hardware or paint stores. The paints were selected to cover a wide range of formulations, pigment volume concentrations (PVC), mechanical properties, and historical exposure results based on our own in-field benchmarking results. Table 1 provides information on the number of paints used in the study based on different sheens and bases. The sheens include semi-gloss, satin, and flat, while the bases include a white and deep (tinted with 12 oz per gallon black colorant) from each sheen.

Continue reading in the May-June digital issue of CoatingsTech