By Brian Vest, Lichang Zhou, Linda Adamson, and Celine Burel, Syensqo

Perfluoro-and polyfluorinated-alkyl substances (PFAS) have been widely used for a variety of applications, including water-resistant fabrics, nonstick cookware, stain-resistant carpets, firefighting foams, food packaging, and some personal care products. Their unique properties of resisting heat, oil, grease, and water make them highly versatile across various sectors. One type of these chemicals, fluorocarbon surfactants (FCS), has been used specifically in waterborne coatings for improving early “hot block” resistance. However, risk management and upcoming regulations are driving formulators to eliminate the use of these chemicals from their formulations. This has led to a balancing act for formulators as they try to move to more sustainable additives without sacrificing performance.

This study will cover the efforts made in our group for the use of novel phosphate ester wetting agents which deliver improved early hot block resistance without the adverse environmental concerns of fluorocarbon chemistry. These novel alkyl phenol ethoxylate (APE)-free and very low volatile organic compound (VOC) specialty additives deliver improved colloidal stability, which helps provide a combination of wetting, dispersing, and compatibility properties to the finished water-based coating. Data will highlight overall paint performance and touch upon structure/property relationships that lead to improved anti-blocking performance.

Introduction

Manufacturers of waterborne coatings are increasingly facing stringent regulatory requirements to transition towards environmentally sustainable formulations. These formulations must not only exhibit low volatile organic compound (VOC) levels but also eliminate hazardous substances such as alkyl phenol ethoxylates (APEs) and fluorocarbon surfactants (FCS). This regulatory landscape presents a formidable challenge for formulators who are tasked with integrating eco-friendly additives while maintaining the integrity and performance of the coatings.

FCS pose a particular challenge for formulators due to their distinctive molecular structure and the comprehensive balance of properties they impart to formulations. A critical performance attribute provided by FCS is early-stage—specifically, 1-day dry—hot block resistance. This property is essential in waterborne semi-gloss to gloss formulations designed for low-VOC applications. For decades, FCS have been instrumental in achieving this performance characteristic without adversely impacting other application properties. However, FCS belong to a broader category of chemicals known as perfluoroalkyl or polyfluoroalkyl substances (PFAS), which are classified as substances of very high concern (SVHC). PFAS are of significant health concern due to their persistent nature, as they do not readily degrade and can accumulate in the environment and in the human body over time, earning them the moniker “forever chemicals.”1 Consequently, there is mounting regulatory pressure globally to identify safe and environmentally benign alternatives to fluorosurfactants across various industries.

In response to the demands within architectural coatings, an extensive study of alternative technologies was undertaken, with a concentrated emphasis on waterbased architectural coatings. This rigorous investigation identified that modifications to a specific phosphate ester chemistry could provide an effective solution, yielding superior early-stage hot block resistance while maintaining a comprehensive balance of application properties. This research culminated in the development of an innovative anti-blocking additive tailored for waterborne coatings.

Background

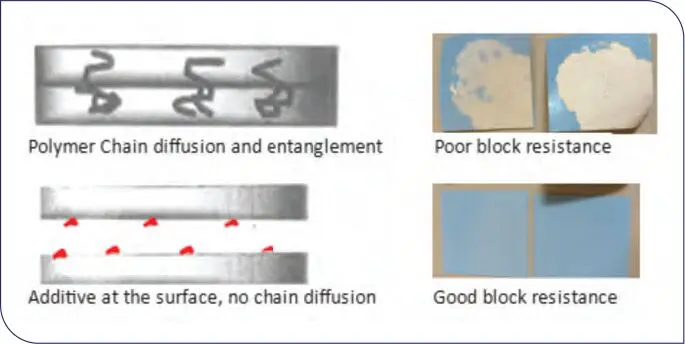

Block resistance is the capability of a paint when applied to two surfaces to not stick upon contact when pressure is applied under various temperature and humidity conditions. For example, good block resistance helps keep a door from sticking to the jamb or a window from sticking to its frame. When the two painted surfaces are pressed together, chain diffusion and entanglement occur from the mobile polymer chain ends, resulting in poor block resistance. Several factors can influence the blocking resistance of a formulation, such as the polymer Tg, the formulation space, and the type of surface-active additives being used. Figure 1 is a cartoon schematic demonstrating good and poor block resistance.

FIGURE 1 Cartoon schematic of block resistance.

FCS are commonly used to improve blocking resistance in waterborne formulations by providing a “protective layer” at the surface, thereby preventing the polymer-to-polymer entanglement (Figure 1). However, due to the environmental challenges and regulations of fluorocarbon chemistry, formulators need a new additive solution to improve block resistance. The scope of this project was to identify an additive that could be easily used by the formulator, either as a post-add to an emulsion or added directly into the formulation, which could match the block resistance performance of fluorosurfactant chemistry without the environmental concerns.

Continue reading in the January-February issue of CoatingsTech