By Jennifer Mills, John Rabasco, Sunny Wang, Wesley Rauenzahn, and Scott Purtell The Dow Chemical Company

Introduction

In this article, we introduce a new applied method, brush workability, for determining the open time of architectural coatings, that offers good reproducibility and high level of differentiation in lab testing. This method shows validated correlation to real world application, using a selection of commercial paints in a double-blind contractor study.

Open time in architectural coatings is defined as the time after applying a single coat of paint where the film remains wet and workable. It is distinct from the full cure time or time before a second coat may be applied. Poor open time is evidenced by the inability to smoothly blend two areas of coating on a large substrate (within a single coat) and is also correlated to poor leveling as the film dries which can result in brush marks or visible roller pattern. Open time can also be evident during the coating application, where paints with poor open time may exhibit roller picking and poor drag between the drying film and the brush or roller.

There are multiple stages in paint drying, including: (1) Diffusion of water through the coating to the air interface and evaporation; (2) Film compaction and particle jamming; (3) Latex particle deformation under capillary force; final evaporation of water; and (4) Final cure/film compaction and coalescence via polymer entanglement. 1-3 Workable open time is defined by the first two stages.

Current industry standards for measuring open time include ASTM methods such as wet edge,4 dry to touch (DTT),5 and use of automated dry time recorders.1 These methods may be subjective in the ways they are rated and/or applied. Furthermore, many scientists and customers have noted that such methods do not translate well to actual paint application and/or are not physically representative of practical workable open time. This underscores the need for better methods with reduced subjectivity and better correlation to real world application, such as our new method.

Materials and Methods

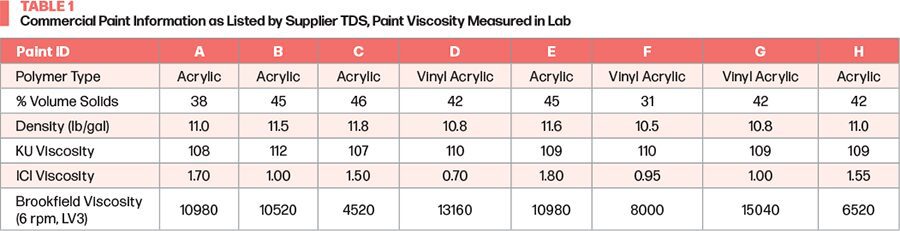

Table 1 details the commercial paints used in this study, with information on technical properties. All paints are eggshell sheen, interior paints. Paint viscosities were measured using the lab viscometers (KU Stormer, ICI, Brookfield LV3/6 rpm). All testing was performed blind, using the paint IDs in Table 1 such that the applicator did not know which commercial paint was being tested. All lab open time tests were performed in a temperature-controlled lab at 75 °F and 50% RH.

Wet Edge: The wet edge test is adapted from ASTM D7488, using two vertical parallel lines running the length of the chart rather than six independent X marks at each time point. Paint was drawn down on a Leneta BK chart using a square bar with 5-mil gap. Immediately following the drawdown, the timer was started and two lines were drawn down the center of the wet film using two parallel tongue depressors. At 1-min intervals, the wet film was brushed over with 15 brush strokes in one direction. The brush was not dipped in fresh paint each time, ensuring a harsher, quicker test. The wet edge open time is the last time when the vertical lines are not able to be seen.

Dry to Touch (DTT): DTT testing was performed using 3 mil drawdowns on BK charts. Following the drawdown, a gloved fingertip was placed in the center of the wet drawdown at 1-min time intervals, and then the wet fingertip was pressed on the chart outside the drawdown area to leave a fingerprint. The paint is considered dry to touch when no finger mark is left. This method is adapted from ASTM D1640.5

Automated Dry Time Measurements: A Gardco circular path dry time recorder was also used for automated drying time measurements of paints. The machine consists of a Teflon ball stylus with a weight on the arm to control force, which moves in a circle through the wet film at a set speed. Tests were done using the 1-h setting, and 5-mil drawdowns on BK charts. The stylus was set approximately in the middle/center of the drawdown. Once complete and dry, the dry path was inspected for four types of signatures according to ASTM procedure D5895.1 There is a transparent overlay to mark the time points corresponding to the positions of each signature.

Continue reading in the September-October issue of CoatingsTech