By Ray Fernando, Olivia Everitt, and Caleb Hall California Polytechnic State University

The main objective of this study is to generate formulating knowledge that can be applied for selecting appropriate solar reflective pigments and fillers for exterior wall coatings of various colors while retaining other important coating properties. A low pigment volume concentration (PVC), all acrylic, white formulation was used as the tint base for all colorants, conventional and infrared (IR) reflective. The key tests included rheology of the wet paints and color, gloss, hiding, and solar reflectance of dry coating films. Commercially available solar reflective materials, such as hollow spherical inorganic and organic particulate fillers and mixed-metal-oxide black and other color pigments and their equivalent conventional pigments were studied. Particular attention was focused on the issue of viscosity instability of tint base when tinted with colorants. Solar reflectance gains from IR-reflective pigments will be presented in comparison to coatings of the same color and other properties, formulated with conventional colorants. Results of this study can be used to estimate cooling energy savings due to incorporation of IR-reflective pigments.

Introduction

The earth receives about 50% of its solar power in the form of ultraviolet (UV) and visible radiation whereas the remaining 50% is in the form of infrared (IR).1 The need for solar power to sustain all forms of life on earth is an unarguable fact. However, excessive amounts of solar power can cause harmful effects. An example of this is the phenomenon known as the heat-island effect.2 Within a highly developed urban center, roofs and pavements receive and trap excessive amounts of solar energy in the form of heat causing greater needs for cooling the interiors of urban structures located in warm climatic regions. The need for cooling adds to the building maintenance cost, increases the building’s carbon footprint, and contributes to air pollution.

The above phenomena and issues have been well recognized for over four decades.3 To mitigate the problems associated with excessive solar heating, solar reflective and heat emission technologies have been developed and widely adapted for roofs and, to a significant extent, to pavements.3-9 According to the Cool Roof Rating Council’s (CRRC) website,10 currently there are 3180 certified roof coating products. Due to the heightened awareness of global warming and ever-rising energy costs, there is a need to extend solar reflective technologies beyond roofs and pavements to other surfaces, such as exterior walls. According to a recent study by Lawrence Berkley National Laboratory’s Heat Island Group, there is great untapped potential for cool coatings for walls.11 However, there are only a few solar reflective coating products for walls, and only 147 certified products are listed on the CRRC website. A literature survey has shown that, although there is increased research activity on heat-reflective coatings for walls, formulation data for commercially viable exterior wall coatings are very limited. The primary objective of this study is to contribute to filling this knowledge gap and enable formulators to develop their own successful products.

Initially, the study focused on understanding and quantifying the heat-reflective performance of conventional waterborne exterior architectural coatings and optimizing the formulations for solar reflectance without the use of specialty heat-reflective materials. All experimental coatings were prepared according to commercially viable formulations. In addition to solar reflectance, other key properties of the coatings, both at wet state and as dry films, were monitored. Results from these types of studies should enable formulators to select solar reflective grades of common raw materials while retaining other important coating properties. The solar reflective materials studied include hollow-spherical inorganic and organic particulate fillers and mixed-metal oxides.

The rheology modifiers used in all formulations in this study are associative thickeners that are sensitive to many formulation variables, including the colorants. As our previous studies have demonstrated,12 this sensitivity used to be a huge problem causing unpredictable viscosity drops of tint bases when tinted with predispersed colorants. A secondary objective of the current study is to assess the magnitude of the associative thickener sensitivity to today’s colorants, both conventional and solar reflective.

Experimental Materials and Methods

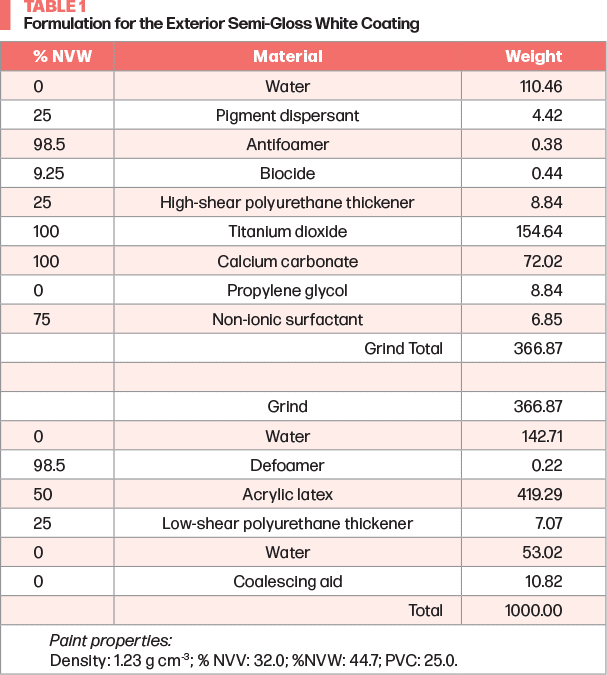

All raw materials used in formulating the coatings are routinely used by the paint and coating industry and were obtained from commercial suppliers. The initial filler (calcium carbonate and nepheline syenite) evaluations were conducted with an exterior flat white formulation, at a pigment volume concentration (PVC) of 43.4 containing predispersed TiO2 and filler (Base Formulation 1 (BF1)). The next set of formulations was prepared with TiO2 in dry powder form (BF2). An example of the latter type, 25 PVC formulation, is shown in Table 1. Our most recent experiments were conducted with a 17.5 PVC, direct-to-metal (DTM) formulation identical to a published study.13 Formulations were mixed with an EMI MXML-STD disperser using a Cowles type blade in pint-sized paint cans at approximately 400 g total weight. The grind step was conducted at 1600 rpm and the let-down step at 1000 rpm.

Continue reading in the September-October issue of CoatingsTech