By Chun Liu, Kathryn Neely, Leon Estell, Nicole Wise, Lehong Jin, Kevin Janak, Arxada

Over the past couple years, hygienic paints and coatings have gained significant attention due to their continuous protection against the COVID-19 virus. Recently, the EPA published its interim guidance on the “Review for Products Adding Residual Efficacy Claims,” which requires ≥ 3 Log10 reduction of bacteria and virus after chemical treatment and dry abrasion in order to claim residual efficacy of paints and coatings. In this article, the development of hygienic paints using a proprietary insoluble copper (iCopper) and hydrophilicmodified DDAP/DDAB quaternary ammonium compound (Quat) technologies is presented. The antibacterial and residual efficacies per the Japanese Industrial Standard JIS Z2801 and the EPA interim method have demonstrated that the iCopper technology can achieve residual efficacy of ≥ 4 Log10 reduction in representative latex paints. In addition, the data have shown the full compatibility of the iCopper technology with latex paints and its impact on paint color can be further minimized by formulation optimization. Other dry film properties such as scrub and stain resistance were also tested and results did not indicate any negative impact from the iCopper technology. Conversely, DDAP/DDAB Quats give < 1 Log10 reduction of bacteria in latex paint per the JIS Z2801 test method even though Quat is an important biocidal active in disinfectant products. This finding may be attributed to the limited mobility of Quat molecules in the dry film as a result of strong electrostatic attraction between cationic Quat and anionic latex particles. The data suggests a significant paint reformulation is required to enable good efficacy of DDAP/DDAB Quat. In summary, the iCopper technology would provide a more costeffective viable solution to meet the EPA residual efficacy claim for hygienic paints and coatings.

Introduction

Microbes such as the novel SARS-CoV-2 virus can survive on surfaces, which facilitates their acquisition and transfer to humans. As a result, hygienic paints and coatings have gained significant attention in the past couple years for their continuous protection against the COVID-19 virus. In early 2021, EPA published their interim guidance on the “Review for Products Adding Residual Efficacy Claims.”1 Hygienic paints and coatings fall into the category of “Supplementary Residual Antimicrobial Products.” For a residual efficacy claim to be supported, a ≥ 3 Log10 reduction of bacteria (Staphylococcus aureus, Pseudomonas aeruginosa) and viruses (most difficult to kill) after chemical and dry abrasion must be achieved.

Copper/silver and quaternary ammonium compounds (Quats) are well-known for their antibacterial and antiviral efficacies.2,3 Currently, there are only a few hygienic paints on the market. For example, PPG recently developed an architectural paint using a cuprous/Cu(I)-based technology from Corning,4 while Sherwin-Williams launched an antimicrobial paint derived from alkyl dimethyl benzyl ammonium chloride (ADBAC) Quat.5 However, significant challenges still exist for developing copper or Quatbased hygienic paints that can meet the EPA residual efficacy claim. Copper technology must have good compatibility with acrylic paints while its impact on color needs to be mitigated. Conversely, cationic Quats are normally incompatible with latex paints, the latter of which are stabilized by anionic surfactants. Therefore, paint reformulation is sometimes required to accommodate Quat(s), which is time- and effort-consuming.6

In this article, we report on the development of a hygienic paint using patent-pending insoluble copper (iCopper)7 and proprietary hydrophilicmodified DDAP/DDAB Quat technologies to meet the EPA residual efficacy claim. Antibacterial efficacies were evaluated by both the Japanese Industrial Standard JIS Z2801 and the EPA interim method to assess their initial and residual efficacies. Potential mechanisms of actions will be proposed to explain the observed efficacies. Other dry film properties, such as color, scrub, and stain resistance, were also tested to ensure no negative impacts resulted from the iCopper technologies.

Experimental Procedure

Preparation of Hygienic Paints

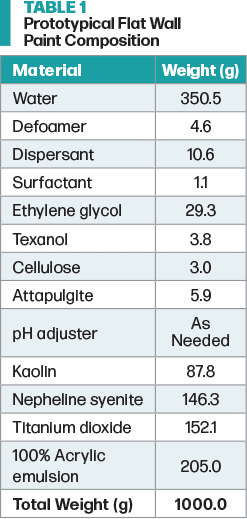

The iCopper and DDAP/DDAB Quat technologies were evaluated in one prototypical interior flat paint (50% PVC, 35% Solid Vol, 45 g/L VOC, Table 1) prepared internally and two commercial paints (one matte wall paint: 41.5% Solid Vol, < 50 g/L VOC; one semi-gloss interior paint: 37.45% Solid Vol, < 50 g/L VOC) were purchased and used as received. The iCopper product was postadded into the above paints followed by speed-mixing for homogeneity. The Cu level ranged from 165 to 1670 ppm. For comparison, 5% copper sulfate (CuSO4) aqueous solution was also post-added into the paints to achieve 330 to 1165 ppm Cu level. For the Quat-treated paints, 5% aqueous solutions of DDAP/DDAB Quats and an ADBAC (ADBAC: alkyl (C14 50%, C16 10%, C12 40%) dimethyl benzyl ammonium chloride) Quat benchmark were individually post-added into the paints to achieve 2000 ppm Quat level. All the treated paints were equilibrated overnight prior to any tests.

Continue reading in the July-August digital issue of CoatingsTech