By Shih-Wa Wang, Cameron Stevens, Siddharth Chanpuriya, Jonathan Antal, Austin Boyd, and Michael Wolfe, Axalta Coating Systems

Automotive manufacturers are increasingly interested in drop-ondemand (DOD) inkjet technology for its potential to enable high-resolution, on-demand customization while improving paint shop efficiency and sustainability. Compared to traditional spray application methods, DOD technology offers significant benefits in reducing volatile organic compound (VOC) emissions, minimizing paint waste, and eliminating the need for masking and demasking processes. However, applying automotive coatings via DOD presents unique challenges due to the high solids content, viscosity, and shear-thinning behavior required for environmental compliance, application feasibility, and appearance quality.

Unlike conventional inkjet inks, which are Newtonian and low viscosity (<20 cP), automotive paints require specialized formulation and process adaptations to ensure reliable jetting. This article explores the integration of piezoelectric DOD technology with a circulation system to address key challenges such as maintaining jetting stability, achieving clean droplet break-off, preventing nozzle drying, and controlling undesirable wetting behavior. Here, we demonstrate successful jetting of waterborne and solventborne automotive coatings, highlighting the role of rheological control, droplet throw distance management, and defect mitigation strategies. Through collaboration with industry partners, these key learnings were implemented in trials printing on an automotive body. Results confirm the feasibility of this approach for OEM-scale implementation, bringing DOD technology closer to practical automotive manufacturing applications.

Introduction

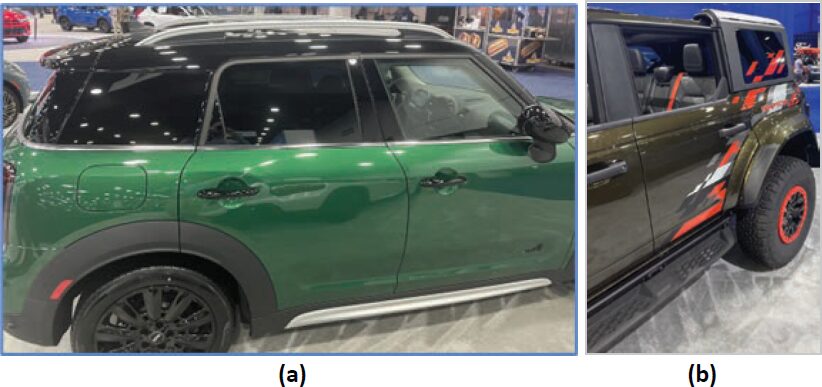

The demand for personalized car designs has been increasing in recent years, with the “Tutone” two-tone color scheme (Figure 1a) experiencing a resurgence. This design, popular in the 1950s, has made a comeback as customers are willing to pay a premium for customization.1 However, manufacturing a Tutone vehicle presents several challenges, including increased volatile organic compound (VOC) emissions from additional paint consumption, waste from masking and demasking, higher labor costs, and a more complex, time-consuming production process.

Another popular but currently non-OEM-compatible customization method is graphic design (Figure 1b) or even logos. This is typically achieved using decals, which are labor-intensive to apply. More intricate graphic designs are executed using vinyl wraps.

Drop-on-demand (DOD) inkjet technology has been used for complex graphics for years, and, in 2022, Boeing demonstrated its potential on the 737 Max 9.2 Given this precedent, can a similar approach be applied to the automotive industry? The answer is yes, but with key differences. Inkjet printing traditionally relies on depositing individual pixels of cyan, magenta, yellow, and black inks. Such an approach does not result in a continuous protective coating required for automotive application.

OEM-Compatible Processes for DOD

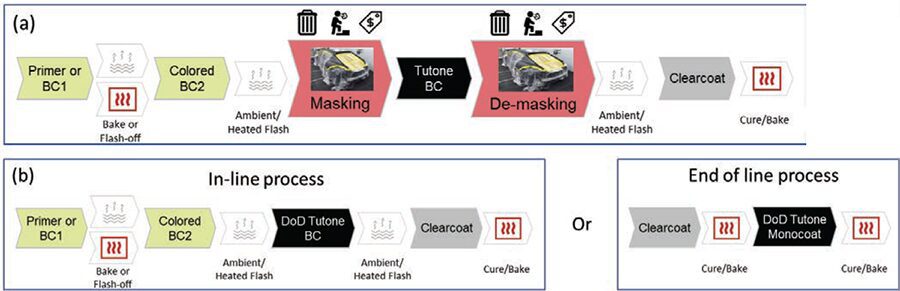

Figure 2a illustrates how current Tutone vehicles are manufactured and the masking and demasking steps are wasteful and labor intensive. With DOD, we propose two OEM-compatible options: one in-line and one end-of line process (Figure 2b). Both would work for Tutone as well as graphic designs.

FIGURE 1 Examples of Tutone (a) and graphic (b) design.

FIGURE 2 (a) Current OEM process for Tutone vehicles. (b) Proposed in-line and end-of-line processes.

Piezoelectric DOD Inkjet and Circulation System

DOD technology generates droplets only when needed, achieved through various methods. Common techniques include (1) thermal, which is suitable only for waterborne (WB) inks; (2) valvejet, which offers low resolution and flow rate; and (3) piezoelectric, which is compatible with both WB and solventborne (SB) formulations and is the preferred method.3

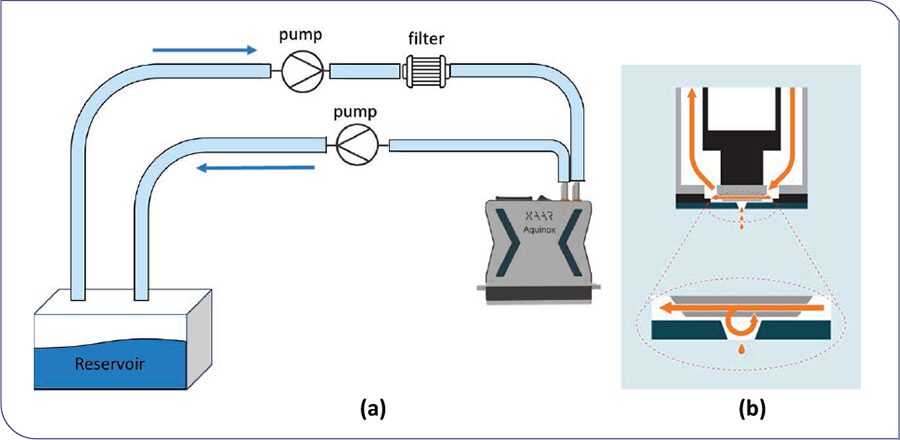

In piezoelectric DOD, the printhead walls are composed of piezoelectric materials that deform when a voltage is applied.4 This deformation generates a pressure wave that ejects a droplet from the chamber behind the nozzles. We found that combining piezoelectric DOD with a circulation system significantly enhances paint jetting performance.

Figure 3 presents the system diagram. The paint circulates between the reservoir and printhead, driven by two pumps. A differential pressure of approximately 100–200 mbar is maintained to ensure a consistent flow rate, keeping the printhead chamber adequately supplied. A final-stage filter is installed before the printhead to capture large particles that could clog nozzles and channels. A mild negative pressure (meniscus pressure) of approximately -10 to -20 mbar at the nozzle prevents paint oozing and nozzle plate flooding while still allowing droplet ejection when triggered by the piezo-induced pressure wave. Precise and stable control of paint supply and meniscus pressure of the printhead is critical to good jetting.

FIGURE 3 Piezoelectric DOD with circulation system. (a) Setup of circulation system. (b) Cross section of the printhead to illustrate the paint circulating behind the nozzles.

Shear Rate Considerations

Paint experiences a wide range of shear rates throughout the system. Shear rate is near zero in the reservoir, around 100 s–1 in tubing, increases to ∼10,000 s–1 in printhead channels, and reaches ∼100,000 s–1 or higher at the nozzles (10–50 μm in diameter). Traditional piezo DOD inks are low-solids, low-viscosity (<20 mPa·s), and Newtonian, whereas paints have significantly higher solids content, viscosity, and exhibit shear-thinning behavior.

Figure 4 illustrates shear rates at various locations and presents examples of jettable WB formulations. Unlike inks, paints require higher pressure to achieve comparable flow rates due to their higher viscosity. Additionally, shear-thinning paints are often thixotropic. Without a circulation system, inkjet operation involves on-off cycles, leading to fluctuations in viscosity, pump demand, and system pressure, which can negatively impact jetting quality. Continuous circulation mitigates these fluctuations, stabilizing jetting performance while preventing aggregate and air bubble formation. Since automotive paints often contain fast-drying solvents, circulation also prevents nozzle drying.

Continue reading in the November-December issue of CoatingsTech