By Kaliappa Ragunathan, Nicholas Foley, and Sofia Goodrich-Accolla† BASF Corporation

Sufficient open time is essential for achieving painting efficiency and delivering aesthetically pleasing results in architectural coatings. The open time can vary widely for an exterior coating because the wet coat may experience extreme weather conditions from humidity and temperature changes to varying wind speeds. Additionally, the open timeof the coating can be influenced by solids, pigment volume concentration, polymer composition, rheology modifiers, additives like humectants, and solvents.

The open time and early rain resistance are seemingly diametrically opposed properties, and it is difficult to improve the early rain resistance without negatively influencing open time. Through the use of statistical design of experiments, this study identified polymer structure factors that can influence the open time and early rain resistance of the paints. The rain resistance was tested using the shower head test method, while the open time was tested using conventional methods such as ASTM 7488 and Gardco Quadracycle drying time.

Further insight on open time was gained by a novel test method using diffusing wave spectroscopy which provides information on critical steps of the film formation process such as water evaporation-concentration, particle packing, particle deformation, and film dry through. Combining this data with polymer structure study allowed for the elucidation of structure-property relationships, specifically regarding open time. The resulting novel insights helped in the development of new polymer prototypes that positively influence both early rain resistance and open time.

Introduction

Weather, especially rain, has a severe impact on the film formation of freshly applied paint on an exterior wall. A fastdrying paint will provide early resistance to rain. However, developing1,2 a fast-drying paint with sufficient open time is challenging. The open time3 of paints has been defined as the period of time during which a painter can make corrections to the freshly applied wet paint film without leaving brush marks. Sufficient open time is essential for achieving painting efficiency and delivering aesthetically pleasing results in architectural coatings. The open time of the coating can be influenced4,5 by solids, pigment volume concentration, polymer composition, rheology modifiers, additives like humectants, and solvents.

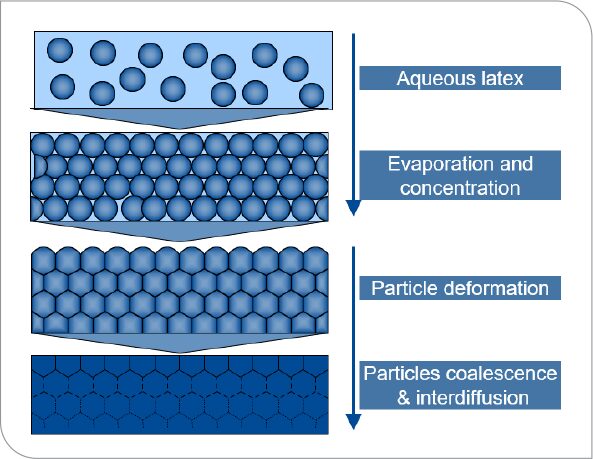

Film formation6,7 from polymer dispersions is schematically depicted in Figure 1. It is expected that water-based paints undergo similar stages, such as water evaporation-concentration, particle packing, particle deformation, and particle coalescence-interdiffusion, to form a coating. The water evaporation stage strongly influences the open time of the paint. The drying conditions of the paint, including temperature, humidity, and air flow, have a significant impact on the water evaporation rate and open time. Low temperature, high humidity, and stagnant air will slow down water evaporation and increase open time. Conversely, high temperature, low humidity, and high-velocity air flow will speed up water evaporation and reduce open time.

FIGURE 1 Film formation in polymer dispersions.6, 7

In this research, we studied the polymer composition to improve the open time without compromising early rain resistance. Statistical design of experiments was used to identify polymer structure factors that can influence the open time and early rain resistance of the paints. Multi-speckle diffusing wave spectroscopy8,9 was used to gain understanding on the critical steps of the film formation process such as water evaporation-concentration, particle packing, particle deformation, and film dry through. Diffusing wave spectroscopy is an extension8 of classical dynamic light scattering to concentrated and opaque media. The diffusing wave spectroscopy and polymer structure factor data were analyzed to develop new polymers with improved open time without compromising early rain resistance.

Experiments

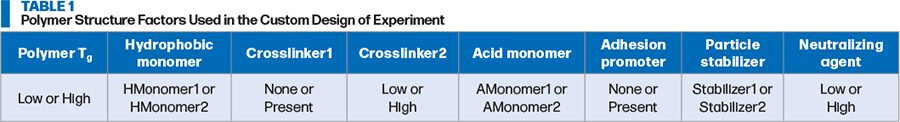

To study the effect of polymer composition on the open time and early rain resistance, a custom design of experiment using JMP® was carried out. The design consisted of eight structure factors of a control polymer dispersion and the details of the design are given in Table 1. Paint formulated using this control polymer provided better early rain resistance and equal open time compared to a leading national brand commercial paint. The goal is to improve the open time of this paint by changing the control polymer structure without reducing the early rain resistance of the paint.

Sixteen different polymer dispersions were synthesized using this design strategy and the composition differences of these polymer dispersions are given in Table 2. These polymer dispersions were synthesized by conventional emulsion polymerization using unsaturated monomers, emulsifiers, and initiators. These polymer dispersions have approximately 53% solids content. Two polymer dispersions, Nos. 1 and 14, were not stable and so they were eliminated from the study. For studying the main effects using this JMP® custom design, the minimum number of runs required is only 9.

Continue reading in the January-February digital issue of CoatingsTech