Coatings Application Process

During manufacturing, some vehicles are painted with a two-wet monocoat paint process. This process uses a primer coat that requires only a few minutes of open-air drying time before the color coat is applied. The color coat is formulated with the same appearance and protection properties of the clear coat, which eliminates the need for a separate clear coat. The painted body is fully cured in an enamel oven after the color coat is applied.

The total process removes one paint application step and one oven drying step when compared to conventional paint processes. This technology reportedly results in more durable paint, uses less energy and water, and reduces carbon dioxide and particulate emissions compared with conventional paint processes.

Source: Axalta

Fuel Efficiency

Many coating products help make vehicles lighter or improve the rolling resistance of tires, enabling automakers and suppliers to produce fuel-efficient vehicles. In addition to improving fuel efficiency, the processes are conducted in a manner that reduces energy and water consumption and decreases the waste produced. In fact, certain corrosion-effective pre-treatments that reduce water use and waste, and increase energy efficiency can save the average North American assembly plant 16 million gallons of water per year — the equivalent of 380,000 10-minute showers.

Source: CoatingsTech

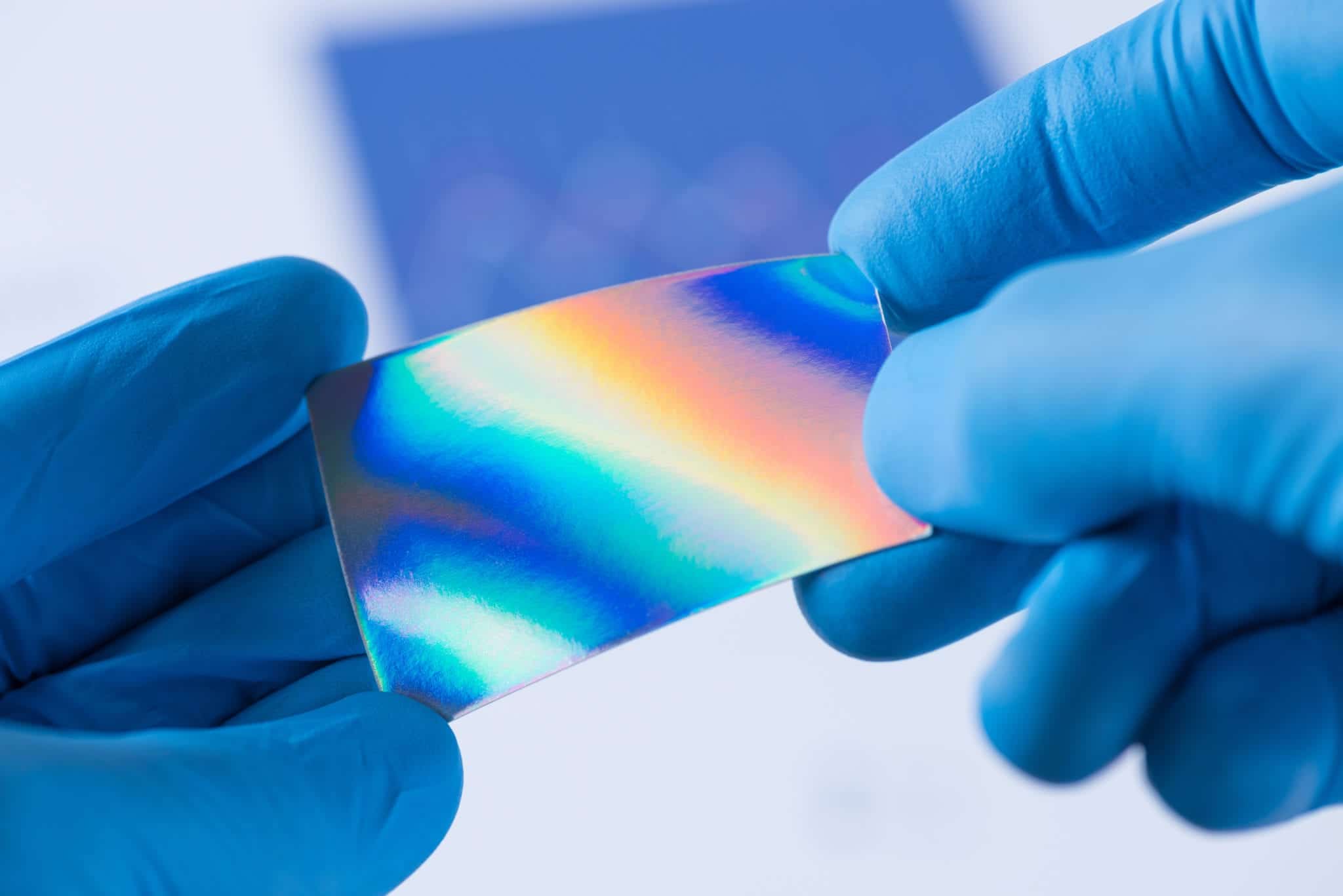

Powder Coatings

Powder coatings as an auto-body coating alternative ushered in a new era for automotive manufacturers who are keen to reduce both their carbon footprint and their costs without compromising on technical quality or performance. Such powder coating systems reduce the number of process steps and enable significant reduction in energy consumption.

Source: Interpon Powder Coatings

Hi-Tech Additives

Many additives are made from bio-based molecules, especially those in automotive and industrial paints, and give those waterborne paints a better carbon footprint: they enable faster drying times and provide a smoother finish. When automakers paint cars, they typically pass them through an oven twice to speed the drying process. Such additives make it possible to eliminate one of the baking steps, thus reducing the overall energy consumed. Another benefit: the faster drying time can also increase the number of cars that can be painted during a work shift.

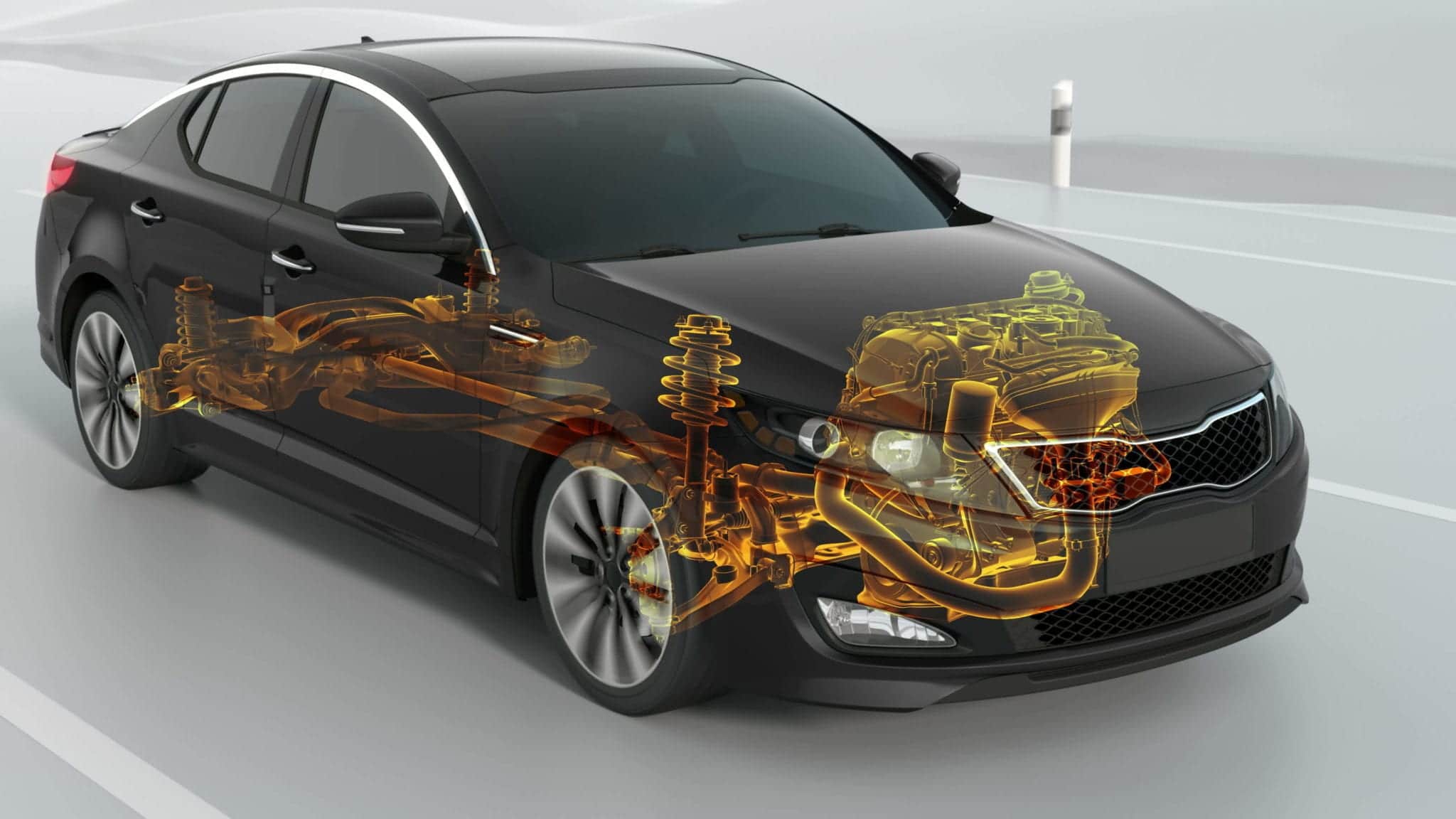

Coatings Engineered for EV & Hybrid Vehicles

Coatings for electric and hybrid vehicles provide key performance attributes that contribute to safety and fuel efficiency. Electrically insulating coatings help control temperature for superconducting batteries and extend battery-life. And coatings systems developed for newly introduced lightweight metals and composites used by EV and hybrid automakers help with “lightweighting” to achieve better fuel economy and reduced CO2 emissions. Moreover, coatings that are compatible with EV computer drivers, sensors, and communications systems are designed to be easy-to-clean, while simultaneously retaining their hydrophobic and transmissive properties.

Source: Products Finishing + CoatingsTech