By Emma G. Wrigglesworth and Eldon W. Tate, Inhibit Coatings Ltd.

Microbial contamination on surfaces is a problematic and potentially deadly issue, particularly in high-risk settings such as healthcare, aged care, and food and beverage. In this research, we present an antimicrobial waterborne polyurethane additive that will be of interest to the coatings community due to its high compatibility with a variety of coating systems, which results in a range of highly diverse and useful applications.

This next-generation antimicrobial uses a nano-composite approach to create a silver-based active ingredient that is non-toxic and truly non-leaching. The presented technology produces strong binding between silver and the polymer backbone. This prevents leaching while retaining high activity with proven results against a range of pathogens.

Introduction

Each day, approximately 1 in 31 U.S. hospital patients and 1 in 43 nursing home residents contract at least one infection associated with their healthcare.1 Healthcare-associated infections accrue direct costs to U.S. hospitals of at least $28.4 billion each year.2 Healthcare settings are just one example of a high-risk area where the transmission of disease is dangerous and expensive.

Silver is well known for its excellent antimicrobial properties, and many products have been produced that exploit this.3-5 These products typically work via the controlled release of silver ions or nanoparticles, resulting in concerns over the release of silver into the environment and the interactions it subsequently undergoes.6-8

Countering this risk, a novel process has been developed that binds the silver active ingredient directly to a polymer backbone, creating a nanocomposite from which the silver does not leach.9,10 This produces an antimicrobial material that is not only sustainable and environmentally friendly, but also displays incredible longevity as the active ingredient is not depleted.

In this research, a water-based silver-polyurethane nanocomposite material has been developed that displays antimicrobial activity against bacteria, viruses, and fungi. Its high potency means it can be utilized as an additive in other coating systems, and its compatibility with a range of materials has been shown, including acrylates, polyurethanes, and other waterborne systems.

As a result, this antimicrobial additive can be used effectively in a range of highly diverse applications (textiles, walls and floors, furniture, high-touch surfaces, filters, etc.).

Experimental

The silver-polyurethane composite was produced using Inhibit Coatings’ proprietary functionalization process.

Characterization

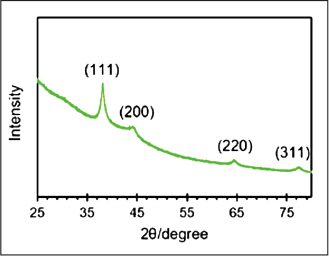

X-ray diffraction (XRD) was used to confirm the crystalline structure and composition of the silver particles within the polymer. A PANalytical X’Pert PRO diffractometer was utilized with a copper K-alpha X-ray source at a wavelength of 1.5405 Å, operating at 45 kV and 40 mA.

A JEOL 2010 transmission electron microscope (TEM), operated at 200 kV, was used to visualize the silver particles within the polymer. The silver-polyurethane composite was diluted and then drop cast onto 200 mesh copper grids and plasma treated with a JEOL EC-52000IC ion cleaner prior to TEM analysis.

Independent Testing

Antimicrobial Testing

Antibacterial testing of the silver-polyurethane composite applied to a polyester textile was conducted according with the AATCC 100-2019 standard11 by Microbe Investigations Switzerland (MIS). The sample was tested against Escherichia coli (E. coli) (ATCC 8739) for a contact time of 24 hours.

Antiviral testing of the silver-polyurethane composite in a polyurethane coating on acrylic was conducted according to the Japanese Industrial Standard JIS Z 2801 standard (modified for viruses)12 by Microchem Laboratory. The sample was tested against Human coronavirus (ATCC VR-740, Strain: 229E) and Influenza A virus (H1N1) (ATCC VR-1469, Strain: A/PR/8/34), for a contact time of 2 hours.

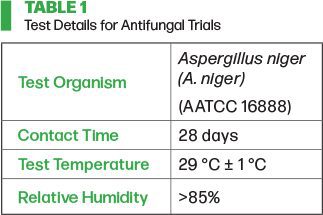

Antifungal testing of the silver-polyurethane composite in a polyurethane coating on acrylic was conducted according to the ASTM G21 standard13 by Microbe Investigations Switzerland (MIS). The test details utilised are provided in Table 1.

Leach Testing

Leaching of silver from the silver-polyurethane composite was conducted by Nanosafe, Inc. Testing of the composite applied to fabric samples followed U.S. EPA Method 1311 “Toxicity Characteristic Leaching Procedure,”14 adapted for the assessment of silver-leaching potential from textiles.15 Testing of the composite applied to wood samples was conducted under guidance of OECD 313 “Estimation of Emissions from Preservative-Treated Wood to the Environment.”16

Toxicology Testing

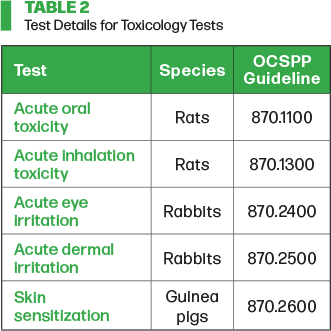

Toxicology testing, as outlined in Table 2, was conducted by STILLMEADOW, Inc., on the silver-polyurethane composite.

Preservative Testing

Preservative testing was run using a Difco Paddle Tester over three weeks, using three concentrations of the silver-polyurethane composite in a polyurethane dispersion, and testing weekly for bacterial growth.

Results and Discussion

Silver Particle Characterization

Characterization techniques have verified that metallic silver nanoparticles have formed.

The XRD pattern of the silver-polyurethane composite has shown peaks with 2θ values of 38.2°, 44.3°, 64.5°, and 77.6° (Figure 1), which can be attributed to the (111), (200), (220), and (311) crystallographic planes of face-centered cubic (fcc) silver crystals, respectively.17

Continue reading in the May-June digital issue of CoatingsTech