Editor’s note: This column is a roundup of notable product releases from the coatings and allied industries. To submit a product release for consideration, email publications@paint.org. Please note that all submissions are subject to editorial approval and publication is not guaranteed.

Paint Thickness Gauge

BYK-Gardner Instruments has introduced its BYK-µPELT 5 handheld paint thickness gauge for multi-layer measurement. According to the company, PELT gauges are essentially acoustic microscopes that use very high-frequency, ultra-short pulses of ultrasound to resolve and measure layer coating thickness.

The company says the compact, lightweight gauge with color touch-screen display can measure up to five individual layers in the range of 4–300 µm, and it can measure both individual layer thickness and total thickness at each measurement location. Commonly used for automotive coatings, the tool can be used on any substrate, including steel, aluminum, plastics, composites, and wood.

For more information, visit byk-instruments.com.

Dispersion and Milling Unit

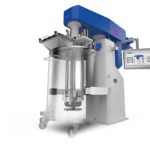

IEC+ has introduced the Plusmill Evo, the latest evolution of its Plusmill. The updated system integrates pigment dispersion and milling within a single unit. The company reports that the updated mill reduces waste, processing time, and contamination while optimizing manufacturing processes and minimizing health and financial risks.

IEC+ has introduced the Plusmill Evo, the latest evolution of its Plusmill. The updated system integrates pigment dispersion and milling within a single unit. The company reports that the updated mill reduces waste, processing time, and contamination while optimizing manufacturing processes and minimizing health and financial risks.

IEC+ also introduced the integration of Cowles Impeller Technology, which is designed to enhance dispersion efficiency and guarantee thorough mixing of pigment particles with the liquid medium. This results in uniform particle distribution and flawless color development.

According to the company, the compact design minimizes accident risks and protects operators from exposure to moving components, creating a safer workspace. An integrated control system fine tunes key parameters, such as particle sizes, to adjust the milling process for desired outcomes, while an advanced cooling system maintains optimal operating temperatures to preserve the integrity of the pigment dispersion.

Learn more at plusmillevo.iecplus.com.

New Paint Atomizer

ABB has launched the RB1000i-S, a new paint atomizer for efficient and sustainable paint shops. The new atomizer mounted on top of the ABB robot improves transfer efficiency by upwards of 10% and can significantly reduce paint waste by a minimum of 30% along with carbon dioxide (CO2) emissions, compared to its predecessor, the RB 1000i.

ABB has launched the RB1000i-S, a new paint atomizer for efficient and sustainable paint shops. The new atomizer mounted on top of the ABB robot improves transfer efficiency by upwards of 10% and can significantly reduce paint waste by a minimum of 30% along with carbon dioxide (CO2) emissions, compared to its predecessor, the RB 1000i.

The company says the atomizer reduces CO2 and volatile organic compounds (VOC) emissions in automotive paint shops by reducing paint waste and overall energy consumption in plants through a more efficient paint process.

Customers can order the new RB 1000i-S atomizer with a new paint robot, or they can purchase a service kit to upgrade their existing RB 1000i by replacing key components, such as the bell cup and shaping air nozzle.

For further information, visit global.abb/group.

Particle Technology for Metal Effect Powder Coatings

AkzoNobel has introduced the Interpon D Natural Metals, a range of powder coatings developed in response to rising demand for sustainable metal-effect architectural finishes.

The collection features patented stabilized particulate technology that the company says is designed to result in a more concentrated, deeper metallic finish than conventional metallic powder coatings.

Designed to protect and enhance even in the most challenging environments, the range features a broad palette of super-durable, on-trend finishes, including copper, brass, steel, nickel, silver, and iron.

According to the company, it contains no volatile organic compounds (VOCs) and is more sustainable in application, because any overspray can be captured and reused, leaving virtually zero waste.

For more information, visit interpon.com.

Fully Automated Dispenser for the Car Refinish Industry

Fully Automated Dispenser for the Car Refinish Industry

Sherwin-Williams Industrial has introduced the Collision Core Pronto, a closed-circuit, fully automated dispensing unit that it says can mix six formulations at once. It can be used with a spectrophotometer where the color code from the spectro is communicated seamlessly for the most accurate color creation for every repair job.

Available in selected regions, the dispenser has four dosing systems that work simultaneously. Its modular configuration fits a range of 16 to 96 units. It can dispense as little as 0.01 grams accurately amounts impossible to achieve with manual dispensing— making the process optimal for small repairs.

According to the company, the fully automatic dispenser minimizes product waste, increases efficiency and eliminates drying issues, dispenses in all climates, and needs no cleaning.

For more information, visit industrial.sherwin-williams.com