Chemical Agent Resistant Coatings

Some coatings are engineered to be self-decontaminating to protect military firearms, tactical vehicles, equipment, and uniforms by neutralizing organophosphorous chemical agents such as sarin. Such government-specified Chemical Agent Resistant Coatings (CARC) have been developed for military personnel and first responders, creating a safer environment for soldiers and first responders by mitigating the immediate impact of contact with nerve agents.

Source: The Sherwin-Williams Company

Stealth Coatings Technology

Radar-absorbing materials like polyurea can be used to provide stealth to advanced military aircraft. Stealth aircraft like the F-35 Lightning II make use of radar-absorbing coatings to reduce their radar cross-section, which is a measure of how detectable an object is with radar detection. For expensive aircraft, which can cost up to several hundred million dollars per unit, avoiding detection and interception is among the military’s first priorities.

Source: ArmorThane

Defending Infrastructure

A military-specified coating creates a hardening effect that offers blast mitigation in buildings, including embassies and defense installations, and is designed to provide a fast, cost-effective alternative to traditional structural steel or concrete systems. This coating was specifically designed to meet criteria requirements of the U.S. Department of Defense Anti-Terrorism Force Protection.

Source: Courtesy of PPG Government Solutions, PPG Industries Inc.

Fighting Corrosion

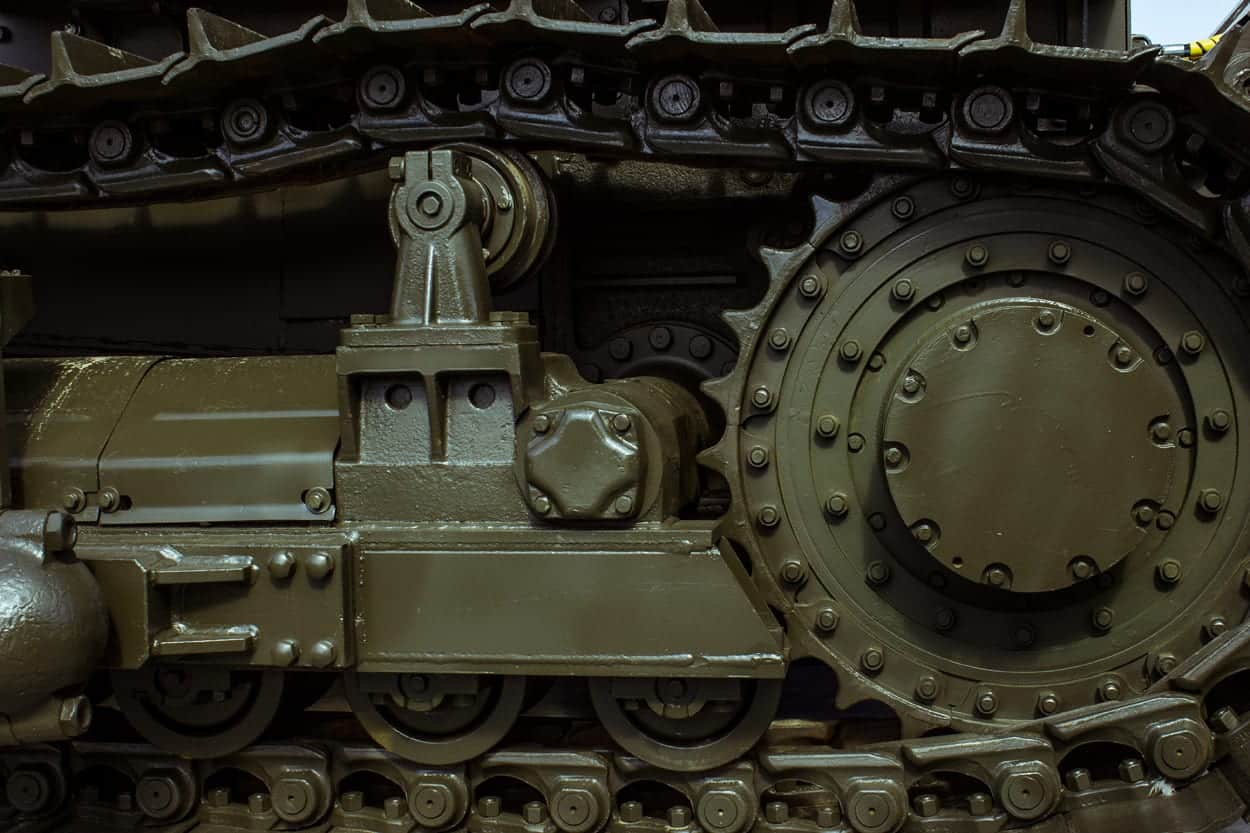

The U.S. coatings industry has been recognized as a key player in the fight against corrosion of our military ships, planes and tanks. Corrosion of steel, aluminum, and other structural metals erodes the safety and financial stability of industries and countries alike. Fighting corrosion in ships, tanks, planes and equipment costs the Pentagon $22.9 billion a year. Corrosion costs advanced industrialized nations about 3.5% of GDP to replace damaged material and components, plus a similar amount due to lost production, environmental impact, disrupted transportation, injuries, and fatalities.

Source: Department of Defense Fiscal Year (FY) 2018 Budget Estimates; Office of the Secretary of Defense

Navy Ships that Last

Saltwater is the ever-present, costly enemy of Navy ships — a major cause of corrosion. New anti-corrosion marine coatings with military performance specification battle the costs and offer longer service life (2-3 times the longevity). They require less maintenance and can be cleaned versus repainted, which is more environmentally prudent because it requires fewer coats.

Source: The Sherwin-Williams Company