Editor’s note: The following online exclusive examines the crucial role coatings play in protecting bridge and extending their service life. Following the article is a special Q&A with industry leaders who share their thoughts on present and future of the bridge coatings market.

By Leo Procopio, Paintology Coatings Research LLC

Bridges are critical to society because they facilitate connections between people and businesses. People need to see their friends and family, workers need to get to their jobs, and goods need to get to their market. Allowing the transport of people and goods across physical barriers such as waterways, ravines, and highways is necessary for our social and economic health.

Due to their importance, it is in the best interest of society to build new bridges when needed, keep existing bridges in safe and working condition, and protect them against excessive degradation from overuse, weather, and corrosion. However, therein lies the problem, as bridges are also very expensive to build and maintain.

Coatings certainly have an important role to play in the protection of bridges from the elements of the weather and corrosion, and effective coating systems can extend their service life and increase the time between maintenance cycles. This article will explore some of the challenges facing our bridges, the role of coatings in bridge construction and maintenance, and the types of coating systems that are currently used on bridges. CoatingsTech also reached out to several experts in the field of bridge coatings for their thoughts on topics such as challenges for bridge maintenance, trends in the bridge coatings market, and where the market is headed in the future. Their comments will be presented in the Q&A roundtable section of this article.

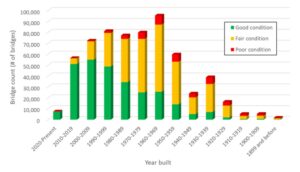

Figure 1. Number of bridges in the current U.S. bridge inventory and their condition, according to their age (year built). Based on data from the National Bridge Inventory as of June 2022.1

The State of Bridges in the U.S.

According to the National Bridge Inventory (NBI), a database administered by the Federal Highway Administration, there were more than 620,000 road and highway bridges in the United States as of June 2022.1 The inventory of bridges has been steadily growing over the decades. For example, 30 years ago, there were slightly more than 570,000 bridges. The inventory of road and highway bridges includes major bridges across mighty rivers, small bridges of at least 20 feet, as well as highway bridges and overpasses spanning other roads or other obstructions such as railroad tracks or gullies. The NBI database doesn’t cover bridges dedicated for rail traffic, and although there is not an exact accounting of railroad bridges in the United States, there are at least 61,000 bridges used for Class 1 rail traffic,2 i.e., the largest rail carriers that account for about 94% of freight rail revenue and 67% of freight rail mileage.

The condition of infrastructure in the United States gets a lot of attention, especially when it’s not in good repair, and road and highway bridges are no different. The American Society of Civil Engineers provides an annual Infrastructure Report Card on various infrastructure segments, and in 2021, it gave the bridge segment only a C grade.3 We tend to take the condition of bridges for granted, but high profile bridge failures, such as the 2007 collapse of the I-35W Mississippi River bridge in Minneapolis or the more recent 2022 collapse of the Fern Hollow bridge in Pittsburgh, focus public attention on the state of our bridges.

Figure 2. Bridge condition for all US bridges and the subset of National Highway System (NHS) bridges, by bridge count (chart on left) and by bridge deck area (chart on right). Based on data from the National Bridge Inventory as of June 2022.1

As might be expected, older bridges tend to have more wear and tear, and a higher percentage of older bridges are rated at a lower condition. Figure 1 shows data for the entire inventory of 620,669 bridges in the NBI, broken down by age (year built) and the overall condition of the bridge. The condition ratings of good/fair/poor are based on the National Bridge Inspection Standards,4 and they consider the combined condition of the deck (i.e., road surface), sub-structure, and super-structure of the bridge. A rating of poor does not necessarily mean that a structure is unsafe, but rather that it needs attention. Approximately 40% of all bridges were constructed before 1970 and are more than 50 years old. It is clear from Figure 1 that a higher percentage of those older bridges are in fair or poor condition compared with those built more recently.

Figure 2 shows the conditions of the entire inventory of U.S. bridges and a comparison with the subset of bridges that are part of the National Highway System (NHS). The National Highway System consists of roadways and major arteries deemed important to the nation’s economy, defense, and mobility. Bridges carrying NHS roads make up about 24% of all bridges by number. However, because these bridges tend to carry larger roads, they make up a larger percentage of the inventory, about 58%, when considering the deck area.

Most are owned by state, county, and local governments (Figure 3). States own about 48% of bridges in number, and local governments own about 50%. However, states generally own the larger and more heavily travelled bridges, and so own approximately 76% of bridges by deck area. The federal government owns a little under 2% of all bridges, such as those on federal lands.

Figure 3. Distribution of bridges by type of owner, according to bridge count (left) and bridge deck area (right). Based on data from the National Bridge Inventory as of June 2022.1

Although the number of bridges characterized as in poor condition has been trending downwards over many years, there are still about 43,000 bridges listed in the recent NBI data as being in poor condition. Funding for bridge construction and repairs has been a perennial problem, and while state and local governments own most bridges, funding is largely from federal sources. In 2021, approximately $8.6 billion was obligated towards bridge projects from federal highway program sources. There had been no standalone federal funding sources dedicated to bridges since 2013, but the recent Infrastructure Investment and Jobs Act (IIJA), enacted at the end of 2021, now provides two funding programs dedicated to bridge projects. It is estimated that these new programs could roughly double the annual spending by states for bridge projects relative to 2021 levels (not adjusted for inflation).5

Painting Bridges

Coatings are utilized on bridges to improve their aesthetics, but protection is their most important function. Bridges in the United States are most commonly constructed from reinforced concrete (about 75%) and steel (about 25%). There are reasons for coatings both substrates.

Problems with concrete occur when water and soluble salts penetrate the concrete and cause the steel reinforcing bar to corrode. As the rebar corrodes, the expanding corrosion products can cause cracks in the concrete. The use of powder coated rebar can help mitigate the issue, and sometimes silane-based sealers and water repellants are applied to the concrete to prevent the water/salt penetration. Pigmented coatings such as epoxies, acrylics, and polyurethanes are also applied to concrete bridges for both aesthetics and barrier protection. However, concrete bridges are largely left uncoated.

Steel bridges, on the other hand, are almost always painted to protect the steel from corrosion. Some bridges constructed from a specific steel alloy, referred to as weathering steel, can be left unpainted, as the steel alloy develops a patina or protective layer during weathering. But in most cases, steel will corrode rapidly if left unpainted. Corrosion can be accelerated when soluble salts are present, such as from road de-icing salts.

Certain areas of bridges are more susceptible to corrosion due to their micro-climate. Steel located under leaking deck joints is in an aggressively corrosive environment. Splash zones, which are more prone to having water and salt splashed onto the steel surface, exist both above the bridge deck surface and sometimes underneath a bridge where another road passes. Any areas that can trap water/salt and remain wet for longer periods of time, such as bottom flanges on I-beams, also have an aggressive micro-climate.

Coatings for Steel Bridges

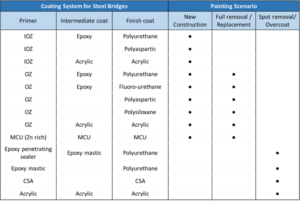

Table 1. Common Coating Systems for Painting Steel Bridges Note: IOZ = inorganic zinc rich, OZ = organic rich zinc, MCU = moisture cure urethane, CSA = calcium sulfonate alkyd

Historically and up to the mid- to late 1970s, many steel bridges were painted with multiple thin coats of alkyd coatings containing toxic corrosion-inhibiting pigments such as chromates and red lead and which were applied directly over the mill scale. Mill scale is a thin layer of iron oxides that forms on hot rolled steel during the milling process. It adheres to the steel surface, and as long as there is no break in the layer, protects the underlying steel. However, because it is electrochemically cathodic to the steel, any breaks in the mill scale can lead to corrosion of the underlying steel. Red lead alkyd coatings were effective, but eventually replaced due to regulation of the toxic lead and chromate pigments and recognition of the benefits of surface preparation (i.e., removal of mill scale via abrasive blasting).

Coating systems comprising a zinc-rich primer and solventborne vinyl finish coat replaced the red lead alkyds in the 1980s. However, the vinyl finish coats were eventually replaced with other topcoats due to their extremely high VOC levels. Today, the bridge industry uses many types of coatings systems, but the most common is a three-coat system comprised of a zinc-rich primer, an epoxy intermediate coat, and an aliphatic polyurethane topcoat.

There are various scenarios in which a steel bridge might be painted, and the choice of process has a large effect on the overall cost of the painting process. The cost of paint materials is typically only a relatively small percentage of the total project cost, with the main contributions coming from labor and the type of surface preparation. If removal of old lead-based coatings is required, the health and safety requirements for the lead abatement process will drive costs up further.

Figure 4. New bridge spanning the Mississippi River and carrying I-74 between Bettendorf, IA, and Moline, IL. Opened to traffic in 2021, all exterior steel surfaces were coated with a three-coat system using a zinc-rich primer, epoxy midcoat, and fluorourethane topcoat. Photo courtesy of AGC Chemicals Americas.

For new construction, it is common to paint the structural steel in a shop setting, where surface preparation and paint application are most easily controlled. After abrasive blasting in the shop, typically at least a zinc-rich primer is applied. Sometimes the full coating system including intermediate and finish coats is also applied in the shop, or alternatively the remaining coats can be applied in the field after the steel is erected.

For maintenance painting, several possible scenarios exist.6 Spot repair and touch-up is used when there are smaller areas of corrosion or paint failures, and those areas can be treated by various surface preparation methods and painted. Zone painting is used to remove and replace coatings in specific areas or zones, such as steel within a splash-zone or within a certain distance from expansion joints. Spot repair and overcoating is used when the original paint system is still in relatively good shape and well adhered. After partial removal of failed coating and rust, spot priming is done, and a full coat of topcoat is applied. Finally, full removal of the old coatings and replacement with a new multi-coat system can be done when the original coating is in poor shape.

Although less expensive on a square foot basis compared with spot repair and zone painting, full removal and replacement is generally the most expensive maintenance painting scenario overall, due to the large surface area being prepared and painted. Overcoating is a less expensive option than full removal/replacement because of the lower amount of surface preparation. Spot repair and zone painting have the highest cost per square foot, but are the lowest overall cost due to the smaller areas being repaired.7

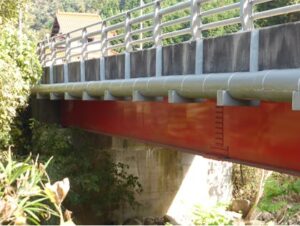

Figure 5. The Tokiwa Bridge, located in a mountainous region near Hiroshima, Japan, was painted with a three-coat system in 1986. The coating system uses a zinc-rich primer, epoxy midcoat, and fluorourethane topcoat, and has performed well for over 30 years. Photo courtesy of AGC Chemicals Americas.

Table 1 lists some of the common coating systems used for steel bridges. The ultimate choice of coating system depends on factors such as the painting scenario (e.g., new construction, full removal or replacement, or spot removal or overcoating), expected durability, as well as immediate and/or life-cycle costs.

For new construction, an inorganic or organic (e.g., epoxy or moisture-cure urethane) zinc-rich primer is typically applied in a shop setting. For field-applied systems, organic zinc rich primers would be utilized. Sacrificial zinc-rich primers are used because they are the most effective primers at preventing corrosion of properly prepared (abrasive blasted), clean steel. There are several types of two- and three-coat systems used for new construction and full removal/replacement of old coatings, as shown in Table 1. As mentioned previously, the most common is a three-coat system using a two-component epoxy intermediate coat and a two-component aliphatic polyurethane topcoat over the zinc-rich primer. The zinc-rich primer provides the corrosion resistance, the epoxy midcoat protects the primer and adds to corrosion resistance via its excellent barrier properties, and the polyurethane topcoat provides a highly durable finish with excellent gloss and color retention.

There is a trend towards using ultra-durable topcoats with excellent gloss and color retention, and one approach is to use a polyurethane based on a fluoropolymer polyol, such as FEVE (fluoroethylene vinylether). An example of a recent bridge coated with such a system is shown in Figure 4. The bridge spans the Mississippi River, carrying I-74 between Iowa and Illinois, and was opened to traffic in December 2021. Protecting the steel on this $1 billion project is a three-coat system consisting of a zinc-rich primer, epoxy midcoat, and fluorourethane topcoat.

Similar coating systems based on fluoropolymers have been used elsewhere in the world, specifically in Japan, for many years. Figure 5 shows an example of such a bridge near Hiroshima, Japan, which was coated with a three-coat system using an FEVE-based fluorourethane topcoat in 1986.8

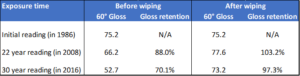

Table 2. Gloss and Gloss-Retention Data for the Fluorourethane Topcoat on the Tokiwa Bridge Near Hiroshima, Japan, Over a 30-Year Period

Table 2 shows some gloss and gloss retention readings made on the Tokiwa Bridge over the course of three decades, illustrating the excellent gloss retention with these systems. After wiping to remove dirt from the painted surface, it was found that the 60° gloss retention was 97% after 30 years. The photographs in Figure 6 illustrate the excellent gloss observed on an external-facing fascia beam, which is expected to receive the most exposure to sunlight and weather, over the 30-year exposure.

Another trend has been to use two-coat systems, in effect replacing the epoxy midcoat and polyurethane topcoat with a single finish coat.9 Utilizing a bridge coating system with fewer coats is advantageous for its lower cost of labor and faster return-to-service (e.g., less downtime for traffic lanes). Polysiloxanes are used directly over zinc-rich primers in a two-coat system and also provide superior durability.10

Figure 6. Photos of a steel fascia beam on the Tokiwa Bridge taken at various exposure times, and showing excellent gloss retention of the fluorourethane topcoat. The photo taken in 2016 represents 30 years of exposure. Photos courtesy of AGC Chemicals Americas.

Fluorourethanes and polysiloxanes are among the most UV-resistant and durable finish coats available today, and both have excellent gloss and color retention. Polysiloxanes are also used in other market segments where durability is important, such as marine coatings.

Polyaspartic finish coats,11 based on amine-functional aspartate ester resins (e.g., Figure 7) crosslinked with aliphatic polyisocyanates, are also utilized in two-coat bridge coating systems.12 Relative to polyurethanes, polyaspartic coatings can offer faster dry times with reasonable pot lives, can be applied at higher film thicknesses, and offer equivalent gloss and color retention. The thicker films facilitate moving to a two-coat system without sacrificing corrosion resistance.

Work on two-coat bridge coating systems continues. Figure 8 shows a highway bridge in Missouri that was recently painted with a proprietary 2-coat system based on new technology from Carboline.

Figure 7. Molecular structure of an amine-functional polyaspartic resin, which can be crosslinked with polyisocyanates (X = aliphatic or cycloaliphatic bridging group, and R = alkyl).

Waterborne acrylic topcoats also get some use in both two- and three-coat systems over zinc-rich primers for full removal/replacement scenarios, as well as find use in multi-coat overcoating scenarios. Acrylics have good exterior durability, the benefit of low VOC, and testing has shown that they can perform well in aggressive environments typical for bridges.13,14

As regulations have pushed end-users towards lower VOC coatings, they have several options to move away from high VOC solventborne coatings, including the replacement of traditional solvents with VOC-exempt solvents and the use of either high solids solventborne coatings or waterborne coatings. A number of states, such as California and North Carolina, have specifications that allow the use of waterborne acrylics on steel bridges. California has recently pioneered the use of several waterborne coatings based on acrylic/FEVE blends as higher durability waterborne options.15,16

State departments of transportation (DOTs) maintain qualified product lists (QPL) or approved product lists (APL) of coatings and coating systems that are approved for use on bridges in their state. A coating typically undergoes a long process of testing prior to being placed on a QPL. State DOTs can do their own testing, and there is also a national program administered by the American Association of State Highway Transportation Officials (AASHTO) that generates data on coating systems that states can use in determining whether a system can be approved for use in their bridge projects.

Figure 8. Photo of bridge carrying I-270 over Dorsett Road in Maryland Heights, just outside of St. Louis, MO. The steel structure was painted with a new proprietary two-coat system. Photo courtesy of Carboline.

The AASHTO National Transportation Product Evaluation Program (NTPEP) evaluates materials and products across a variety of applications and includes a program for steel bridge coatings. The program helps prevent duplication of testing efforts across state DOTs and provides paint manufacturers with a single testing protocol rather than having to support testing done by each state separately. The NTPEP Structural Steel Coatings program evaluates products via an independent third party laboratory according to a consensus-based project work plan that describes the laboratory and field test protocols.17 Testing includes demanding accelerated weathering tests such as 5000 hours in ASTM B117 salt spray and 15 cycles (5040 hours) in ASTM D5894 cyclic salt fog/UV exposure, as well as slip coefficient testing for coatings applied to faying surfaces (i.e., surfaces being bolted together), among others. Results are shared with member states via an online database18 and used to make decisions about qualifying products for inclusion on a state’s QPL/APL.

Conclusions

The vast importance of bridges to society lies in the numerous social and economic connections that they facilitate. The United States currently has over 620,000 road and highway bridges that allow people and products to get over obstacles such as waterways, valleys, and roads which would otherwise be difficult to traverse. Unfortunately, many of them are rated as being in poor condition. Building new bridges and replacing unsafe or obsolete bridges is very expensive, so protecting and maintaining existing bridges against deterioration is incredibly important.

Coatings have a key role to play in protecting critical infrastructure such as bridges. Bridge coatings have evolved over many decades to become safer and more effective, and today, a three-coat system based on a zinc-rich primer, epoxy intermediate coat, and polyurethane topcoat is most common. However, many other systems are used, including ones utilizing more durable finish coats (e.g., fluorourethanes and polysiloxanes), environmentally friendly waterborne coatings, and systems with fewer coating layers. The challenges facing bridges and other infrastructure are many and daunting, but there is no doubt that future innovations in coatings will be part of the solution.

References

- Information on the National Bridge Inventory database, maintained by the Federal Highway Administration, can be found at https://www.fhwa.dot.gov/bridge/nbi.cfm.

- “How Freight Railroads Keep More Than 61,000 Bridges Safe,” Association of American Railroads

- “2021 Report Card for America’s Infrastructure,” American Society of Civil Engineers, accessed at https://infrastructurereportcard.org/.

- Info on the National Bridge Inspection Standards can be accessed at https://www.fhwa.dot.gov/bridge/nbis.cfm.

- “Infrastructure Investment and Jobs Act: Highway Bridges,” Congressional Research Service, May 2022.

- Ault, J.P.; Kimmer, C.; Shoyer, E., “Maintaining Modern Bridge Coatings Systems,” J. Protective Coatings & Linings, 40(1), pp. 18-27, January 2023.

- Richards, G.; Grisso, B., “Maintenance Painting- Protective Coatings and Coating Systems for Bridges,” presentation at the 2013 Southeast Bridge Preservation Partnership annual meeting, 2013.

- Darden, W., “Long life coatings for steel bridges,” Proceedings of AREMA Annual Conference, 2019.

- O’Donoghue, M.; Datta, V.; Walker, S.; Wiseman, T.; Roberts, P.; Repman, N., “Innovative Coating Systems for Steel Bridges: A Review of Developments,” J. Protective Coatings & Linings, 30(1), pp. 34-52, January, 2013.

- Calzone, T., “Ultra-Durable Finished for Zinc-Primed Steel Bridges,” Proceedings of the World Steel Bridge Symposium, 2005.

- Squiller, E.P.; Reinstadtler, S., “Polyaspartic Coatings,” Chapter 14 in ASM Handbook Volume 5B: Protective Organic Coatings, K.B. Tator (Ed.), ASM International, 2015.

- Olsen, A.; Williams, C.T.; Hudson, M.; Fleming, C.W., “Two-coat Polyaspartic Urethane Coatings Protect Virginia Steel Bridges for Over a Decade,” J. Protective Coatings & Linings, 33(1), pp. 56-63, January 2016.

- Medford, W., “Testing Low VOC Coatings in Aggressive Environments: North Carolina’s Experience,” J. Protective Coatings & Linings, pp. 23-29, May 1995.

- Peart, J.; Kogler, R., “Environmental Exposure Testing of Low VOC Coatings for Steel Bridges,” J. Protective Coatings & Linings, pp. 60-69, January 1994.

- Marcks, B., “Improvements of Waterborne Acrylic Latex Finish Paint Properties by Incorporating Fluoroethylene Vinyl Ether (FEVE) Emulsion Technology,” Proceeding of the SSPC Coatings+ Conference, 2020.

- For example, see State of California Department of Transportation Specification PWB-182B, “Dark Green Finish Paint Waterborne Acrylic Latex/ FEVE Blend Vehicle,” February 2023.

- “NTPEP Committee Work Plan for Evaluation of Structural Steel Coatings (SSC-18-1),” AASHTO, 2019, accessed at https://ntpep.transportation.org/technical-committees/protective-coatings-ssc-ccs.

- NTPEP DataMine for Structural Steel Coatings (SSC) can be accessed at https://data.ntpep.org/SSC/Products.

Roundtable Q&A: Industry Experts Discuss Bridge Coatings

CoatingsTech asked several industry experts for their thoughts on the present and future of the bridge coatings market. Topics ranged from challenges facing the bridge construction and maintenance industry to trends affecting the market for bridge coatings. They also discuss the role of sustainability in this industry, as well as their thoughts on what the future holds for bridge coatings.

Participants in the Q&A roundtable discussion include experts in the bridge coatings industry from raw material suppliers, coatings manufacturers, engineering firms, and facility owners. The industry experts providing comments include:

- Peter Ault, president at KTA-Tator

- Andrew Birnie, North American market development manager for industrial coatings at Covestro LLC

- Winn Darden, business manager for AGC Chemicals Americas, Inc.

- Vijay Datta, technical leadership and business development manager at International Paints at AkzoNobel

- Justin Manuel, global product line director for Carboline

- Barry Marcks, associate chemical testing engineer with the California Department of Transportation (Caltrans)

- Kevin Morris, director of strategic segments and business development for protective and marine coatings at PPG

Q&A

Q1: From your perspective, what are some of the key challenges facing the bridge construction and maintenance industry?

Ault (KTA-Tator): At this time, the availability of skilled labor and supply chain issues are the prominent problems. As we digest the funding made available through the Infrastructure Investment and Jobs Act (IIJA), we will be back to the enduring challenge of balancing present-day cost with life-cycle costs. Often the life-cycle costs are too obscure to justify higher present-day expenditures.

Darden (AGC): Keeping older assets viable for longer periods of time is a key challenge. Also, new bridge construction has become extremely expensive, as has repainting.

Datta (AkzoNobel): The key challenge is the expense, length of time, and exclusion of emerging technology in the current approval protocol. This is applicable to both new construction and maintenance projects.

Manuel (Carboline): While there are many industries that face significant funding challenges, I believe the bridge construction and maintenance industry is actually in a prime position to thrive in this regard—particularly given the growing emphasis on tackling our nation’s infrastructure corrosion challenges. If more funding continues to be allocated to this industry, I expect that we will see an abundance of new bridge projects added to the DOT dockets in coming years. As a result, this would necessitate the hiring of more skilled labor in order to support these contracts.

Marcks (Caltrans): Some challenges in the construction and maintenance markets include the promotion of unqualified contractors through the low bid process and a lack of experienced QC/QA inspectors. A grey tsunami, involving the retirement of institutional knowledge, and a small pool of qualified new candidates and hires are other issues.

Morris (PPG): The two greatest challenges that I see right now are lack of funding (temporary correction with the IIJA bill) and the need to maximize life cycles so the budget money can address more needs.

Q2: What do you see as some of the important market trends and drivers affecting paints and coatings for bridges?

Birnie (Covestro): The top market driver on everyone’s mind is the potential elimination of exempt solvents, such as PCBTF, which is the most widely used exempt solvent in the industry. The challenge is keeping pace with the productivity demands of the industry and remaining compliant with current and potential future regulations. There are a few approaches coatings companies could take in anticipation of this change—finding a new exempt solvent or developing new coatings systems with waterborne or high solids resins which don’t require any at all. Coatings manufacturers are hesitant about finding a replacement solvent for fear that it could also end up being eliminated someday. Waterborne is an option in this case but could fall short of the productivity needed to be a true replacement. Finally, a high solids option, like polyaspartate chemistry can be formulated to most VOC levels and offers several other benefits, such as fast dry times, early property development, and a faster return to service. As lawmakers work to finalize their regulations, working with an existing chemistry with a proven record of performance is likely one of the most attractive choices for formulators.

Manuel (Carboline): One of the biggest drivers of trends within the coatings industry is a major push toward the development of more sustainable solutions that offer lower VOCs and a reduced environmental footprint. This has been a bit of a challenge for the bridge industry, which has predominantly used solvent-based, higher-VOC coatings in both field and shop environments for the past 50+ years. While this push for sustainability is still fairly new as it relates to the bridge industry, it will certainly be important for coating manufacturers and DOTs to anticipate this “green wave” based on other market trends we’ve seen in recent years.

Ault (KTA-Tator): Since the 1990s, coatings selection for bridges has largely been driven by issues surrounding lead-based paint. Even for new structures, the three-coat zinc-rich/epoxy/urethane (Z/E/U) became the standard replacement for coated steel bridges (uncoated steel also became a popular option). In the past 5 to 10 years, owners have begun optimizing their approaches to coated steel. As the initial Z/E/U bridges are approaching their first maintenance interval, the maintenance community is looking at new maintenance painting procedures—zone painting and new overcoating strategies are becoming common. For both new and maintenance painting, there is increasing interest in and use of color and gloss retentive topcoats. For new structures, the owners are beginning to refine their corrosion control strategies to use both less expensive systems (e.g., single coat inorganic zinc), and pricier systems offering more durability (e.g., duplex coatings consisting of a metallic coating in combination with organic coating(s)). Finally, owners have begun to combine coatings systems to optimize cost and performance. For example, on simple overpasses, several states will apply a full coating system on outside members and omit the finish coat on interior beams.

Marcks (Caltrans): Market trends affecting bridges coatings include the loss of raw materials and products used in making coatings. Supply chain disruptions have caused a lack of availability of some raw materials. Corporate takeovers and acquisitions of specialty materials suppliers is another trend. Inflation and rising costs affect the ability to plan projects. On the EH&S front, Go Green policies are advocating the removal and discontinuation of some products from use.

Darden (AGC): It appears that many DOTs and bridge authorities are more open to concepts like life cycle cost and trying to quantify those costs. Cost per gallon of paint isn’t the relevant metric for coatings, it’s applied cost per square foot per year of coating life. This means that more expensive products like fluoropolymer coating systems are more common today.

Morris (PPG): I think cost and budgets continue to be major impacts for bridges, and during this recent inflationary period several have speculated that the funds that will pour in from the IIJA Bill will only cover the inflationary costs that have been witnessed in the workplace.

Datta (AkzoNobel): The new upcoming trend could be surface prep and application by robotics. The inspection and maintenance can be done by drones. We also believe the current testing protocol should be replaced by ISO 12944 testing. I think ISO has classified environments based on severity, required durability, and expected service life. Their testing protocol is based on these requirements. This new testing/approval protocol should answer all the above questions.

Q3: What do you consider the top challenges for the bridge coatings industry today, and how are they being addressed?

Morris (PPG): What is unique in our world are the silos built around end use segments and the lack of data transfer from one segment to another. The bridge and highway market segment continues to look for ways to meet longer life cycle performance and to achieve the elusive “100-year design life” for bridges. Other branches of government, such as the Navy, looked for life-cycle improvements decades ago, and through technology, they realized improvements of 3x to 4x. Perhaps this rests as much on manufacturers to do a better job telling the story as it does on the bridge industry to become early adopters of new technology so that they realize improvements in performance. Two examples that I would give are edge retentive, ultra-high solids coatings, which could improve protection on areas where corrosion commonly starts on a bridge, and ultra-weatherable topcoats that are more resistant to degradation from UV light.

Datta (AkzoNobel): A key challenge is the cost of being a qualified contractor (QP 1 and QP 2 certifications from AMPP), including capital investments in equipment and containment and the ability to find the proper labor resources. In addition, recent supply chain constraints have either canceled or postponed several bridge projects.

Darden (AGC): One key challenge is trying to get new products qualified in the bridge coating market.

Manuel (Carboline): Although we have seen marked improvement in recent months, disruptions to the supply chain continue to be the biggest challenge that is faced by the bridge coatings industry. Because DOT specifications often follow rigid testing requirements, the approved list of coating solutions from which a contractor can select is very narrow and specific. As a result of ongoing raw material shortages, it has become increasingly difficult to manufacture these products. Ultimately, this can impact the completion timeline for bridge coating projects.

Ault (KTA-Tator): In addition to those mentioned above, the biggest challenge is deciding when new approaches make sense in the absence of long-term performance data to validate the decisions. Public perception often incentivizes near-term performance at minimal cost over solutions that are more cost-effective over the longer-term.

Marcks (Caltrans): Inflation with its rising costs has made everything more expensive. And a small pool of qualified labor has made it more difficult to get the people needed to complete projects. Supply chain issues have caused shortages, even allocation of products and materials. This delayed some projects. The problems seem to have been resolved for now, but will it happen again?

Q4: Are there any new and innovative products or technologies for the bridge coatings industry that you would like to highlight?

Darden (AGC): Newer concepts like duplex coatings can enable significant extension of coating system life. Using long-life fluoropolymer topcoats over galvanized or metallized surfaces can give coating system life beyond that offered by each technology alone.

Marcks (Caltrans): Caltrans has developed UV-resistant, one-component waterborne finish coatings using an acrylic/FEVE blend for use on our structural steel bridges.

Ault (KTA-Tator): As mentioned above, some key innovations include color and gloss retentive topcoats (e.g., polysiloxanes and fluoropolymers), less expensive systems (single coat inorganic zinc-rich, rapid-cure coatings), and pricier systems offering more durability (duplex coatings consisting of a metallic coating in combination with organic coatings).

Morris (PPG): This market segment is one in which it is difficult to innovate. The industry utilizes qualified and approved product lists (QPL/APL) that have to be met, and they either call for specific products/chemistries with minimum performance requirements, or they are formulary in nature.

Datta (AkzoNobel): To our knowledge, coatings innovation for the bridge market is somewhat stagnant due to the long and expensive testing procedures necessary for qualification, coupled with a low margin business. Adapting the new ISO 12944 standard for qualification of bridge coatings may inspire new technology development.

Manuel (Carboline): Carboline will soon be launching an innovative, new two-coat system that will revolutionize the construction and rehabilitation of steel bridge structures. Developed to provide state DOTs with the ultimate corrosion protection, this system will significantly extend the asset life cycle over more traditional, three-coat systems. It will also eliminate the need for block-outs (masking areas where bolted connections are made, so only zinc-rich primers are on faying surfaces) as the entire coating system will adhere to Class B slip coefficient standards.

Q5: How is the bridge coatings industry dealing with the concept of sustainability? Are there any advances in surface preparation, coatings, application methods, etc., that show promise for improving the sustainability of the bridge coatings process.

Manuel (Carboline): While it has been fairly slow to evolve, the bridge industry is seeing a shift from solvent-based, higher-VOC coatings to more sustainable technology. Because new coating systems within the bridge industry are subject to rigid testing standards, some manufacturers may be hesitant to innovate new systems that compromise their current specification positions. That said, as the global coatings industry—and the world—increasingly push for more sustainable coating solutions, I expect that will accelerate the adoption of this trend within the bridge industry.

Ault (KTA-Tator): From my perspective, addressing sustainability is in its infancy. While coatings do have an environmental impact that is magnified with multiple maintenance cycles, the industry doesn’t have a firm grasp on the frequency of such intervals. Perhaps the more significant environmental cost is the so-called user impact. Slowed traffic, underutilized human resources, delayed deliveries are examples of costs associated with bridge maintenance that have a significant sustainability impact.

Morris (PPG): Sustainability is primarily addressed through VOC compliance such as but not limited to Ozone Transport Commission (OTC) Phase II regulations.

Birnie (Covestro): Over the last several years, sustainability has evolved well beyond a buzzword with theoretical implications for the distant future. The bridge coatings industry has begun to define sustainability and establish standards, goals and best practices that are all intended to push the industry toward a more sustainable existence.

Carbon neutrality is perhaps the most tangible example of sustainability drivers the industry is looking to improve. Paint companies are now shifting focus on carbon reduction from embodied carbon, making the choice of building materials, such as bridge coatings, even more critical than it has been in the past. Coatings derived from bio-renewable or recycled raw materials will not only reduce the amount of embodied carbon of a bridge project, but also help companies across the value chain achieve their carbon neutrality goals.

This progress on reducing environmental impact does not mean a sacrifice on performance specifications. Coatings made from bio-renewable raw materials will perform just like their fossil-based versions. When these coatings begin to prove themselves in the field, accelerated adoption is likely to follow.

Marcks (Caltrans): Sustainability is today’s buzzword, and many times it is a vaguely defined term.

Caltrans uses a waterborne FEVE/acrylic latex blend coating that lasts longer and doesn’t have to be repainted as often. This saves tax dollars and enhances sustainability through increased longevity of our coatings and steel structures.

Caltrans has looked into using laser blasting as a surface preparation method to remove existing coating and corrosion to achieve SSPC-SP 10 standards (Near White Metal Blasting). Caltrans is also utilizing UAS or Unmanned Aircraft Systems (drones) for bridge inspection and coating assessment.

Darden (AGC): The use of longer life coatings is one way to meet sustainability standards. Minimizing the need for repainting over multiple cycles reduces the amount of energy and carbon dioxide emissions from manufacturing of the coating, application of the coating, disruptions to traffic, etc.

Q6: Putting your futurist hat on, what do you see as the future of bridge maintenance and the role of coatings? What would you like to see the industry accomplish in the next 10 or 20 years?

Datta (AkzoNobel): We think the biggest barrier for the next 20-plus years is low return on investment due to R&D, testing costs, and final independent lab testing and approval.

Marcks (Caltrans): Coatings provide the primary corrosion protection system for steel bridges. Bridge painting is a cost-effective means of extending the service life of our infrastructure. I would hope to see more funding available for bridge maintenance programs and see the need for higher wages and better incentives to attract and hire painters.

Darden (AGC): The industry has started moving in the direction of more durable materials in coating systems. The ultimate goal should be to use coating systems that protect steel bridges for 50-plus years, moving as close as possible to 100-year coating systems.

Manuel (Carboline): Especially in more recent years, the bridge industry has increasingly shifted away from carbon steel bridges painted with the traditional three-coat system in favor of alternatives like concrete, weathering steel and metallizing (also known as thermal spray). I expect this to prompt a push for new and innovative advancements in bridge coatings technology and data to support these trends and bolster coating systems’ position as the ultimate corrosion control mechanism on steel bridges into the next generation.

Morris (PPG): The future of bridge maintenance and role of coatings does not show much in the way of expected change going forward. The one exception would be the potential addition of ultra-durable topcoats. I would like to see an acceleration of trials/demos for new technologies from coatings manufacturers to prove increased life cycles.

Ault (KTA-Tator): In 10 to 20 years, major bridge rehabilitation will be limited to functional issues (capacity constraints, road realignments, etc.). A properly designed bridge will be able to endure its design life with minimal coating maintenance.

About the Author

Leo J. Procopio, Ph.D., is president and owner of Paintology Coatings Research LLC. For more information, visit www.scienceofpaint.com or email leo.procopio@scienceofpaint.com.