by Aggie Lotz, The ChemQuest Group, Inc.

In 2015, ACA again partnered with The ChemQuest Group, Inc., the global strategic management consulting firm, to publish the ACA Industry Market Analysis, 9th Edition (2014–2019). This article provides an update to the chapter on Marine Coatings, just one of the many market segments detailed in the valuable publication.

Contributors to this article include Frank Szafranski, AkzoNobel’s key account manager/regulatory liaison—Yacht, who serves on ACA’s Antifouling Working Group committee, and Neal Blossom, chair of ACA’s Marine Coatings Committee.

“Biofouling control has tremendous environmental benefits that range from energy savings to slowing the spread of invasive species. Over regulating copper-based antifouling coatings—the most proven and utilized [marine] coatings in the world, which have been universally approved by numerous countries worldwide based on the results of exhaustive human health and environmental studies—is questionable.”—Neal Blossom, director of Global Environmental and Regulatory Affairs, American Chemet Corporation (ACA’s Marine Coatings Committee Chair).

BACKGROUND FROM THE ACA INDUSTRY MARKET ANALYSIS, 9TH EDITION

Antifouling coatings are intended to prevent the encroachment and/or growth of marine organisms (such as barnacles, tubeworms, mollusks, and algae) on the hull or surfaces of structures or vessels immersed and operating in seawater. Fouling increases surface resistance to vessel movement, thereby reducing the speed of the vessel and increasing fuel consumption to maintain speed. In some instances, fouling will also interfere with the operation of equipment or cause the weight design limitations of a structure to be exceeded. Fouling occurs most rapidly on static and slow-moving vessels. The fouling environment is also most intense where nutrients are concentrated, such as coastal areas due to run-off from land; environmental conditions, such as temperature, salinity, pH, etc., also play a role. Hence, the most effective antifouling agents or compositions are broad spectrum (i.e., those that kill or inhibit the settlement of as many organisms as possible).

Historically, organotin compounds such as TBT were used in most high performance antifouling coatings until they were banned more than two decades ago. Since then, copper-based substitutes (typically cuprous oxide) have become the most widely used alternative.

The most successful embodiment of this approach is the contact-leaching composition in which the cuprous oxide level is high and the soluble matrix is toughened with suitable co-resins (flexible, less soluble). The toxin leaches from the polymeric matrix and leaves pores in the surfaces for seawater to penetrate to lower levels of the film, and further leach toxin. However, as noted above, the leach rate is typically excessive during early stages of coating service life and diminishes to an ineffective rate over time.

After the ban on tin-based antifouling, which also contained some copper, most suppliers switched to primarily copper-based coatings. However, a concern regarding dissolved copper from these coatings systems has been identified in certain poorly flushed basins and in crowded marinas where these metals may accumulate and exceed the Clean Water Act standard for copper, which is 3.1 μg/L in marine waters. Scientific studies have shown high concentrations of dissolved copper in ocean water can affect the growth, development, and reproduction of mussels, oysters, scallops, sea urchins, and crustaceans. Since 2012, significant R&D resources have been allocated for the development of copper-free antifouling coatings in anticipation of increasing restrictions, which may be leveled against the yacht market before reaching the broader marine/shipping sectors. One such example is Washington state, which has enacted a ban on antifouling paints that contain more than 0.5% copper for recreational boats, effective January 1, 2020. According to the Washington Department of Ecology, “copper is poisonous to salmon and aquatic life.”

California and the U.S. EPA are conducting TMDL studies. (A TMDL, or Total Maximum Daily Load, is a controlled study that measures amounts and sources of pollution affecting a particular body of water and then proposes regulations designed to reduce discharges to bring pollutant levels below harmful levels.) However, as suppliers of marine coatings are quick to point out, there are major differences between copper and other banned biocides such as TBT. Though copper can be a problem for aquatic life when present in large quantities, it is roughly 1,000 times safer than TBT overall. In particular:

- Copper is naturally occurring in water.

- Copper does not bioaccumulate in food chains.

- There are many sources of copper in the environment; and marine paints are not a major source.

- Copper is a metal so, although it cannot degrade, when released in the environment, it quickly “detoxifies” by binding to organic matter in the water.

In the recreational boat market, buyers include marinas as well as individual boaters. Boating accessory suppliers such as West Marine (consumer retail), Kellogg Marine Supply (subsidiary of Land N’ Sea), Port Supply (owned by West Marine), Donovan Marine, and a plethora of regional players serve a major role in this segment as opinion leaders providing advice for individual boaters regarding products and maintenance schedules. Coating performance is affected by factors such as water temperature, regular vessel maintenance, cleaning methods used, and frequency of boat use. In this segment, the key issues are color, ease of application, safety, and environmental compatibility. About 50% of yacht coatings are applied by boat owners (DIY), while the other 50% are applied by boat yards and marinas. Many boat yards are seeking to expand their share of this market for safety and environmental reasons (i.e., to ensure the coatings are properly applied and that the old coatings are properly disposed of).

THE ECONOMICS OF RECREATIONAL BOATING

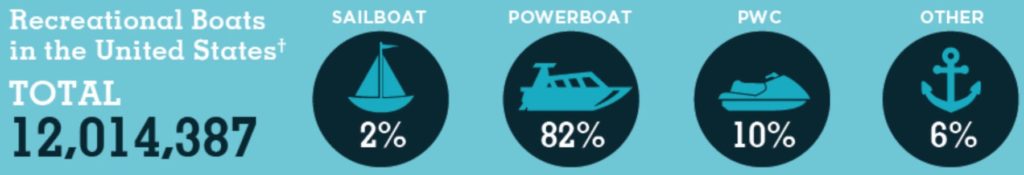

According to the National Marine Manufacturers Association (NMMA), 95% of boats sold in the United States are made there, with the total annual economic impact of recreational boating in 2015 estimated at $121.5 billion involving 34,833 businesses. The breakdown of the types of recreational boats, according to NMMA’s 2015 study of the U.S. Economic Impact of Recreational Boating, is shown in Figure 1. In 2016, NMMA hosted the RNC and DNC with “Day on the Water” events in Cleveland (300 attendees) and Philadelphia (over 225 attendees), respectively—to provide a platform for the industry to engage party leaders in discussions on issues important to NMMA members and the overwhelming positive impact recreational boating has on the U.S. economy. A key issue affecting the Yacht and Recreational Boating sector is the uncertainty of how, when, and to what degree restricting copper-based antifouling bottom paint would be enforced by regulators.

FIGURE 1—Market distribution of recreational boats in the United States (2015). Source: National Marine Manufacturers Association (NMMA), 2015 U.S. Economic Impact of Recreational Boating

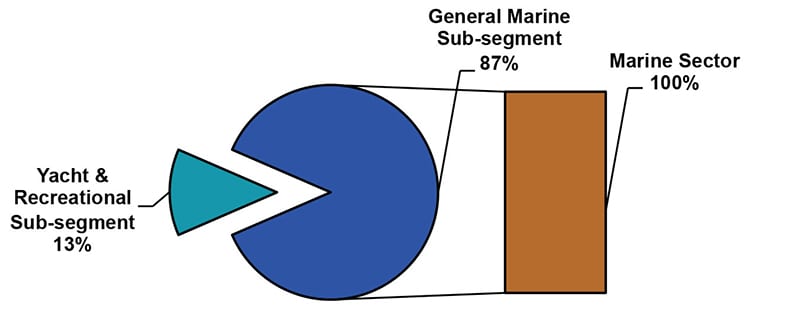

ChemQuest estimates that in 2015, shipments of marine and yacht paint totaled 9.2 million gallons valued at $422 million, of which $367 million accounted for the value of general marine paints and $55 million reflects the value of the yacht paints sub-segment. Market share distributions between marine and yacht coatings, according to the ACA Market Analysis, are depicted in Figure 2.

FIGURE 2—Market distribution of marine and yacht paint (2014). Source: The ChemQuest Group, Inc. estimates

CALIFORNIA’S BOATING CULTURE: THE HULL CLEANING DEBATE

While the water is warm in southern California, it is not warmer than states such as Florida, yet underwater hull cleaning occurs far more frequently in California than anywhere else, which is attributed to California’s boating culture.

As the result of infrequent boat use, unsightly slime caused by algae will accumulate at the boat’s waterline after only three or four months in the water, which—given their all-in costs for pleasure boating—is disconcerting to boat owners. Divers are hired to clean boats below the waterline, which is the beginning of a vicious cycle: over time, even a gentle cleaning with a soft cloth will be detrimental to the efficacy of a copper-based antifouling coating, and will only add to the unsightly slime build-up at the waterline. Responding to growing concern regarding the amount of copper contributed by underwater hull cleaning, the San Diego Unified Port District implemented a Diver Licensing program that requires licensing of divers, continuing education, and hull cleaning according to Best Practices set forth in the SDUPD Ordinance 2681, which amends Code 4.14.

REGULATORY ACTIVITY IN THE STATE OF CALIFORNIA

To renew antifouling registrations, the state of California required manufacturers of antifouling coatings to fund a comprehensive study to evaluate the contribution underwater hull cleaning made to copper in water coves. Study findings indicated that underwater hull cleaning contributed up to 50% of copper detected in the water. Patrick J. Earley’s acclaimed paper, “Life Cycle Contributions of Copper from Vessel Painting and Maintenance Activities,” puts that study finding into proper perspective by concisely characterizing the chemistry of copper levels that exceed water quality criteria. According to Earley’s study findings, even high concentrations of copper can “detoxify” by binding to organic matter in the water, with the caveat that cumulative copper loading—under the right conditions—can exceed the binding capacity of organic matter (e.g., when heavy vessel traffic occurs in certain harbors and marinas with limited water circulation). Earley’s study “helps to quantify some of the complicated variables associated with environmental loading parameters from typical recreational boat paints.” (Note: Earley’s full paper is available on the www.NIH.gov website. The study was conducted under requirements established by the DPR in conjunction with Nan Singhasemanon, and was funded by the American Coatings Association.)

The California Department of Pesticide Regulation, also known as DPR or CDPR, one of six boards and departments of the California Environmental Protection Agency (Cal/EPA), used the aforementioned study findings in its appendix entitled, “Modeling To Determine The Maximum Allowable Leach Rate For Copper-Based Antifouling Products In California Marinas.” At one point, the DPR was poised to include a water quality standard that regulated the frequency of boat hull cleaning—independent of manufacturers’ cleaning recommendations—and notwithstanding DPR’s role to regulate pesticides, not divers who clean recreational boats.

The DPR’s goal was to limit copper concentrations to the levels that are within compliance of current California Toxics Rule (CTR) water quality standards. In their original recommendation, DPR developed three tiers of antifouling leach rates predicated on frequency and methods of hull cleaning—including one tier for antifouling coatings that required “no cleaning”—hoping to get the majority of California marinas into compliance by restricting leach rates to a certain standard that would still allow efficacious coatings for use on recreational vessels. In 2015, the original three-tier draft recommendation was reduced to one leach rate in the final version. Following a comment period from antifouling manufacturers, the DPR revised its original recommendation as follows: the maximum allowable leach rate of copper from antifouling coatings that require periodic cleaning is 9.5 μg/cm2/day.

DPR’s original recommendation included a “no cleaning” antifouling coating and a proposed leach rate of 14.5 μg/cm2/day (with the “no cleaning required” burden of proof falling on antifouling coatings manufacturers) that was eventually dropped in its final recommendation. By whose standard would an antifouling coating product be assessed by its requirement for maintenance cleaning, if any? Industry does not believe there is an objective standard. Clearly, there were many factors for DPR to consider in its collaborative process, which was reportedly a good effort, although many, if not all, participants in the process were not in agreement with the outcome—which is, of course, the very definition of compromise!

DPR’s original recommendation included a “no cleaning” antifouling coating and a proposed leach rate of 14.5 μg/cm2/day (with the “no cleaning required” burden of proof falling on antifouling coatings manufacturers) that was eventually dropped in its final recommendation. By whose standard would an antifouling coating product be assessed by its requirement for maintenance cleaning, if any? Industry does not believe there is an objective standard. Clearly, there were many factors for DPR to consider in its collaborative process, which was reportedly a good effort, although many, if not all, participants in the process were not in agreement with the outcome—which is, of course, the very definition of compromise!

Moreover, DPR’s original recommendations included new warnings on paint can labels related to boat hull cleaning, and an outreach to the general public. In its final recommendation, DPR agreed to remove the labelling requirement, but continues to push for public outreach. Is an “informed” public opinion possible, given the required knowledge of chemistry that would be the basis for a thorough understanding to judge the inherent environmental complexities and viable solutions?

The state of California’s State Lands Commission has also been working to pass a biofouling regulation for commercial vessels traveling in and out of the region to prevent the introduction of invasive marine species. While regulators are demanding the use of best available technology for biofouling control on vessel hulls (recognizing the environmental risks of invasive marine species), concurrently, they are studying the feasibility of enacting bans of hull coatings technology that may be the most efficacious. Coatings formulated with cuprous oxide have been around for at least 100 years, and they are used on the vast majority of recreational and commercial vessels, so it is by far the most proven technology.

NONTOXIC ALTERNATIVES TO COPPER-BASED ANTIFOULING

Nontoxic alternatives to copper-based antifouling coatings fall into one of two categories: biocidal and biocide-free. Biocide-free coatings include the Non-Stick Surface type and the Ceramic-type or hard coatings. Nonstick surface coatings that are often silicone- or fluoropolymer-based and work by preventing biofouling organisms from permanently attaching to the boat hull (i.e., biofouling will sheer off when the boat reaches a certain speed). Hard coatings can be epoxy-based and proprietary blends. Biocidal and biocide-free coatings all require maintenance cleaning. Of those, the hard coatings reportedly require the most cleaning, although there are drawbacks to using each alternative. Zinc-oxide, which is classified as an additive (not a biocide) is also in use and considered nontoxic (albeit has been known to leach zinc over time). Econea™ is an organic metal-free antifouling agent that protects boat hulls.

CONVERSION COSTS AND PERFORMANCE

Well over 90% of vessels, including commercial vessels, reportedly are coated with copper-based antifouling coatings. Many studies have shown that biocide-free antifouling alternatives do not perform as well when compared to copper-based. Consequently, boat owners prefer not switching.

Coatings manufacturers recommend that the boat hull be stripped down to the hull prior to applying the nonstick surface coatings, at a high cost to boat owners. Some boat owners have tried encapsulating copper-based antifouling coatings with the biocide-free coatings, with mixed results. However, over-coating is not recommended by coating manufacturers.

The U.S. EPA awarded a $96,000 grant to test 19 non-stick surface coatings initially on panels, followed by boat hulls, to evaluate the biocide-free coatings performance and cost-effectiveness versus two copper-based control coatings in three regions in California between November 2009 and December 2012. Cost-effectiveness was evaluated due to the costly requirement of stripping off the old copper-based coating down to the hull. Spray-on application can also add to the cost. Therefore, the grantee studied alternative paint stripping and paint application methods including applying the paint with a roller, and even over-coating the copper-based antifouling with the non-stick surface coatings. Details on the study methods and testing times are available online. According to the U.S. EPA, its grantee’s study findings—which do not align with findings of myriad industry studies—were reported as favorable for four of the 19 non-stick surface coatings independent of the three region’s different climates and cold and warm aquatic temperatures.

MAINTENANCE REPAINTING CYCLES

Biocidal antifouling coatings generally require repainting every one to three years, while nonstick surface coatings tend to be more durable (requiring repainting about every five to seven years). By comparison, the life cycle of hard coatings is reportedly the life of the vessel (e.g., despite their reportedly attractive life cycle costs by certain sources, the future of hard coatings and biocide-free coatings is unknown because the “economic case” supporting the use of biocide-free coatings does not yet exist).

REGULATORY ACTIVITY IN THE STATE OF WASHINGTON

The state of Washington could institute a complete ban on the use of copper-based antifouling coatings. Substitute Senate Bill 5436 was enacted into the “Laws of 2011,” through the 62nd Legislature’s 2011 Regular Session. It is entitled “Recreational Water Vessels—Antifouling Paints” and states that beginning January 1, 2020, no antifouling paint that is intended for use on a recreational water vessel that contains more than 0.5% copper may be offered for sale, nor may it be applied to a recreational water vessel, in the state of Washington. A recreational vessel is defined in the law as no more than 65 feet in length.

A new section of Washington’s 2011 law is seeking industry comments through 2017:

NEW SECTION. Sec. 6. (1) On or after January 1, 2016, the director may establish and maintain a statewide advisory committee to assist the department in implementing the requirements of this chapter. (2)(a) By January 1, 2017, the department shall survey the manufacturers of antifouling paints sold or offered for sale in this state to determine the types of antifouling paints that are available in this state. The department shall also study how antifouling paints affect marine organisms and water quality. The department shall report its findings to the legislature, consistent with RCW 43.01.036, by December 31, 2017.

According to one source in the coatings industry, the environmental benefits of efficacious antifouling coatings tend to be overlooked in favor of coatings with less biocide without taking efficacy into full consideration. Some Washington-based NGOs maintain that no coating is safe in terms of water quality, whether it contains an alternative such as Econea, zinc-oxide, or low levels of silicone oil in some of the silicone coatings. There is environmental debate regarding the broader environmental toxicity of antifouling coating biocides and the increased risk of transportation of a higher number of invasive species. Whether the Washington State Legislature will factor in the environmental risk of invasive species introduction and spread versus the benefits of efficacious coatings on the hulls remains to be seen.

AN UPDATE: TOTAL MAXIMUM DAILY LOAD (TMDL)

The Clean Water Act Section 303(d) requires states to list waters that have ongoing failure of water quality standards and to develop a schedule for restoring water quality by various methods at a total maximum daily load (TMDL) limit of 3.1 ppb in copper discharges. Three harbors in California (San Diego, Marina del Rey, and Newport Bay) are currently operating under such TMDL limits. TMDL compliance may require up to an 83% reduction in copper discharges from boat hulls especially during cleaning, for example, by requiring the use of soft pads for—and slip liners during—hull cleaning, as well as the conversion to nontoxic antifouling coatings scheduled during normal boat maintenance repainting cycles. Should municipalities ban underwater cleaning, or ban bottom paints? In San Diego Bay, the Shelter Island Yacht Basin has been identified as “Ground Zero” where high copper levels exceed federal and state standards; flushing action in the harbor has been proposed as part of the solution toward a 76% reduction of copper levels by 2022.

So far, San Diego has been able to comply with the TMDL limits. Generally speaking, compliance with these types of restrictions becomes increasingly difficult over time. For example, if water quality is to be restored with a year over year (YoY) reduction in the TMDL of, say, 20%, demonstrating improvements is relative easy in the first few years versus in years three and four.

The Recreational Boaters of California (RBOC) have been urging the U.S. EPA Office of Water to approve the Copper Marine Biotic Ligand Model (BLM) for metals in salt water to ensure that more accurate marine and estuarine water quality criteria is developed. BLM allows for more scientifically objective benchmarks as the basis for TMDL regulations versus the current one-size-fits-all methods. Widely recognized as a scientifically proven method and currently used in fresh water modeling, BLM measures water chemistry to include an accurate reading of how copper is dispersed in a specific harbor. BLM is the basis for “site-specific” water quality criteria that would be used to determine the appropriate copper pollution mitigation response for each harbor. The EPA has just taken such action and in late July released the Copper Marine BLM for public comment. It is possible that after the comment period, the Copper Marine BLM will be available for the states to adopt in early 2017. According to one source, states can be very slow to adopt new federal standards, but there will likely be significant public pressure to move quickly on this Clean Water Act update.

CONCLUSION

Especially if they do their homework, boat owners in California will have options for biofouling control using existing products on the market (and new products coming to market) that meet the copper leach rate limit of 9.5 μg/cm2/day, although more product development is underway to develop technologies in the 9.5 range before the leach rate is mandated.

In the state of Washington, boat owners may not be as fortunate because formulating an antifouling coating with no more than 0.5% copper is far more challenging. At the conclusion of numerous tax-payer funded studies, there is a role for every stakeholder in the solution—boaters, coatings manufacturers, state agencies, local municipalities, NGOs, and the U.S. EPA—all of whom have weighed in over the years on the environmental effects of biofouling and efficacious coatings for boat hulls. Will the boating public be swayed by conflicting (often factually incomplete and/or subjective) studies in favor of converting to biocide-free coatings? The jury is still out.

Late-Breaking Development

When CoatingsTech’s September issue went to press, in an unexpected change, the U.S. EPA Office of Water used questionable data in its recently proposed revision of its national estuarine-marine copper water quality criteria, based on the saltwater biotic ligand model (BLM), which was recommended to the States (and the California Water Control Boards) for setting their own standards, and site-specific (local) criteria. This change could threaten the development of reasonable and protective water quality criteria and further exacerbate excessive compliance costs incurred by marinas and the boating community in California.

For more information on the ACA Industry Market Analysis, 9th Edition (2014–2019), contact ACA’s Allen Irish (airish@paint.org), or visit paint.org.