Considering Different Preservative Scenarios1

Overview

An industry-led study was conducted to assess the environmental performance of five different architectural coating preservation scenarios using a Cradle-to-Grave Life-Cycle Assessment (LCA). Preservatives play a crucial role in enhancing shelf-life, ensuring the product does not spoil before being used, and protecting the dried coating film from biologic growth. Government agencies around the globe are exploring restrictions and eliminations of these key chemical compounds without consideration of the increased impacts that would result from the currently available alternatives. Representatives of several major coatings, chemical, and trade associations were involved with the creation and completion of this study. The primary goals of the LCA were to determine the environmental impacts and benefits that wet-state and dry-film preservatives play in architectural coating systems, and to see how reducing, eliminating, or replacing certain preservatives impacted the coating’s overall sustainability profile.

Methodology

The LCA was performed using best-practices and developed to be conformant with ISO 14040,2 ISO 14025,3 ISO 21930,4 as well as the calculation rules outlined in American Coating Association’s Product Category Rule (PCR) for Architectural Coatings,5 as follows:

- The functional unit from the Architectural Coatings PCR (covering and protecting 1m2 of substrate for 60 years) was used in this assessment.

- The performance values in this study were developed through industry consensus and are consistent with the values found in publicly available literature.

- Both the water-based and solvent-

based formulas came from industry sources and are a reasonable proxy to actual products available for purchase. - Each formula was modeled to at least 99.9% of its composition (by weight), and all major flows and processes were accounted for in the LCA models.

The following preservative scenarios were considered:

- A typical, water-based architectural coating with preservative level adequate to prevent spoilage (WB)

- A typical, water-based coating using a natural preservative (citric acid) requiring a higher dose, relative to conventional preservatives (WB-N)

- A typical, water-based coating with no preservatives (WB-NP)

- A typical, water-based coating with no preservatives, but assumed to be refrigerated once formulated (WB-NPR)

- A historic solvent-based formula (SB)

The first scenario (WB) was chosen because it represents the current industry status quo of water-based architectural coatings, which have become the norm, given the VOC reductions across the industry to enhance product sustainability. The three scenarios—WB-N, WB-NP, and WB-NPR—were chosen as likely alternatives, should the industry be forced to abandon its current preservation strategy through regulatory or market pressures. The final scenario—SB—is a legacy solvent-based formula selected to demonstrate the significant improvement by environmental impact across the industry in moving from legacy solvent-based chemistries to water-based chemistries for architectural products.

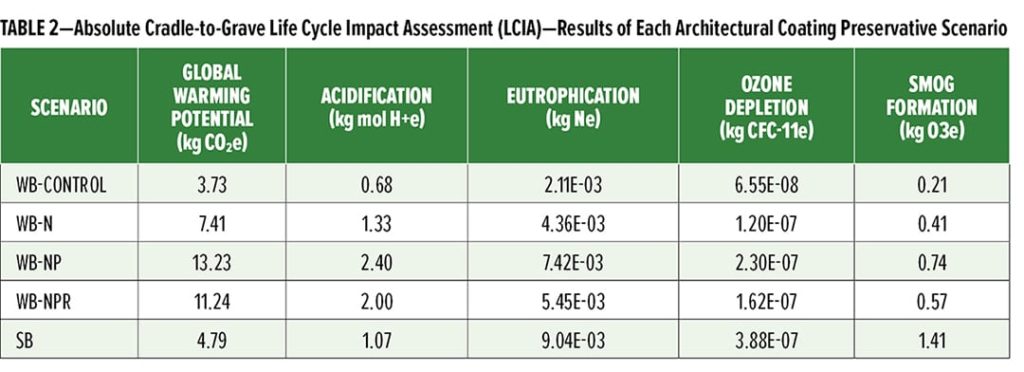

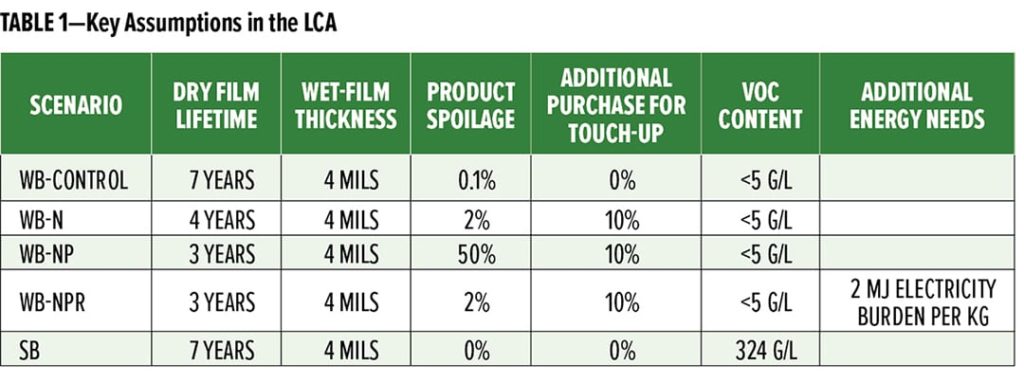

Each of these scenarios was modeled in the GaBi 8.1 software6 using the most current and appropriate life-cycle inventory (LCI) databases, as well as industry assumptions regarding product performance, lifespan, spoilage, and rework. The LCI databases utilized were commercially available, third-party validated datasets including ecoinvent,7 thinkstep,8 and the European Council of the Paint, Printing Ink and Artists’ Colours Industry (CEPE) coating industry LCI.9 Table 1 identifies the key assumptions of the study.

This study highlights that the actual environmental impact of preservatives is extremely modest relative to their benefit, and that the tradeoffs associated with preservative substitution are severe, compared to the other parts of the coating formulation.

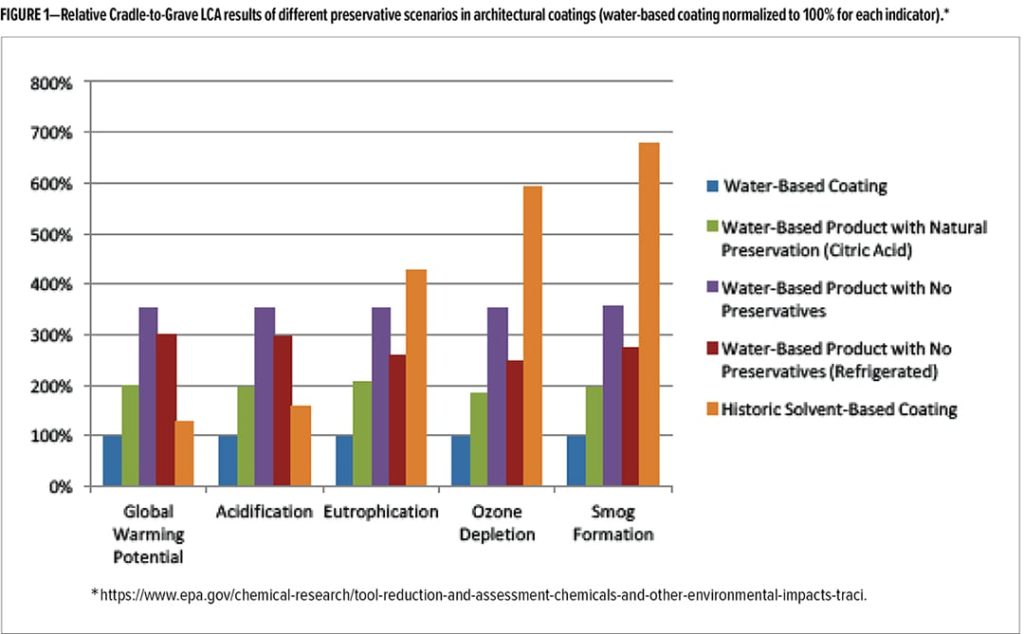

The summary results of the study are shown in Figure 1 and in Appendix A in Table 2.

Results

The results illustrate that any of the non-baseline preservation scenarios led to a substantial increase in the environmental impact of the coating. The relative environmental impact was determined by comparing the WB baseline to the other coating scenarios. The environmental indicators assessed in the LCA were global warming potential, acidification, eutrophication, ozone depletion, and smog formation. In Figure 1, the y-axis indicates the percentage increase in environmental impact relative to the WB baseline scenario. Relative to the baseline scenario, changing the preservation strategy increased the environmental burden of the system, ranging from a 50% higher impact to almost a 400% higher impact, depending on the specific scenario.

The LCA models also showcased that the preservatives themselves were typically responsible for <1% of the total impact in each impact category. This pales in comparison to their importance in the environmental performance and sustainability benefit of the entire coating system.

Finally, the legacy solvent-based system—which would not require a wet-state preservative—was the worst overall environmentally, and shows the significant improvement industry has made by moving from solvent-based to water-based chemistries for architectural products.

The results illustrate that any of the non-baseline preservation scenarios led to a substantial increase in the environmental impact of the coating.

Advocacy Implications

The study results showcase that preservatives play a tremendously important role in coating formulation and that overall product performance must be considered when making formulation changes, since substitutions without considering the effect on product efficacy can greatly increase the environmental impact of the product. Additionally, it is important for regulators to consider the impact on downstream users when reviewing preservatives. The SB coating, while having the similar performance metrics as the WB, has the most significant increase in impact across the environmental metrics modeled in the LCA. The three WB alternatives do not have the same performance metrics as the current WB formula. Pairing the decrease in shelf-life duration and increase in spoilage rates with the increase in the five environmental metrics in the LCA (shown in Figure 1), creates a substantial environmental impact. Moreover, the study’s findings illustrate that increased product loss and spoilage rates experienced under the three WB alternatives would place a significant financial burden on the downstream user.

Preservatives are key components integral for the low-VOC water-based formulations that are used in the marketplace today. For example, when examining the increase in ozone depletion when moving away from the baseline water-based coating, the increases range from 75% (WB-N) to almost 500% (SB). This study highlights that the actual environmental impact of preservatives is extremely modest relative to their benefit, and that the tradeoffs associated with preservative substitution are severe, compared to the other parts of the coating formulation.

Glossary

Adequate Preservation Level: A product with the minimum level of preservation to avoid significant product spoilage and/or early failure.

Citric Acid: A weak organic acid that occurs naturally in citrus fruits.

CEPE: The European Council of the Paint, Printing Ink and Artists’ Colours Industry.

Dry Film: The fully cured coating film after painting.

Dry-Film Preservative: An additive that contributes to reduction and prevention of molds and mildew.

ecoinvent: A life-cycle inventory database that contains international industrial life cycle inventory data on energy supply.

GaBi: Created by PE INTERNATIONAL GaBi, Databases are LCA databases that contain ready-to-use Life Cycle Inventory profiles.

LCA: Life-Cycle Assessment—A technique to assess environmental impacts associated with all the stages of a product’s life from cradle-to-grave (i.e., from raw material extraction through materials processing, manufacture, distribution, use, repair and maintenance, and disposal or recycling), as defined in ISO 14040.

LCI: Life-Cycle Inventory—A central source of critically reviewed, consistent, and transparent data.

LCIA: Life-Cycle Impact Assessment—The LCA phases involving the identification, compilation, and quantification of inputs and outputs associated with the product’s life-cycle. For this study, the LCIA is quantified in Table 2 of Appendix A.

Natural Preservative: A substance added to products to prevent decomposition by microbial growth. This substance exists

in nature and is not made or caused by humans. An example of a natural preservative would be citric acid.

Organic Solvents: Solvents that contain at least one carbon atom and one hydrogen atom, have low molecular weight, and exist in liquid form at room temperature.

PCR: Product Category Rule—A PCR defines the rules and requirements for creating Environmental Product Declarations of a certain product category, as described in ISO 14025.

Product Spoilage: Product that is unusable due to biologic growth.

Shelf Life: The period in which a material may normally be stored and still be in a usable condition.

Solvent-Based Coating: Coatings which contain only organic solvents, if water is present it is only in trace quantities.

thinkstep: A lifecycle inventory database that contains critically reviewed energy and transport data.

VOC: Volatile Organic Com-

pound—Any organic compound that participates in atmospheric photochemical reactions; any organic compound other than those which the EPA designates as having negligible photochemical reactivity.

Water-Based Coating: Coatings in which the volatile content is predominantly water. These include latex paints, emulsion paints, and water paints.

Wet-State Preservative: Preservative that combats the growth of microorganisms during and prior to the use of the product.

TIM WIERONIEY, specialist, Health, Safety, and Environmental Affairs, American Coatings Association

______

1 This report was created by the American Coatings Association Life Cycle Assessment Drafting Team, a subgroup of the American Coatings Association Preservation Product Stewardship Working Group.

2 International Organization for Standardization (ISO) 14040:2006 Environmental management—Life-cycle assessment—Principles and framework.

3 ISO 10425:2006 Environmental labels and declarations—Type III environmental declarations—Principles and procedures.

4 ISO 21930:2007 Sustainability in building construction—Environmental declaration of building products.

5 https://standards.nsf.org/apps/group_public/document.php?document_id=28098.

6 Created by PE INTERNATIONAL, GaBi Databases are LCA databases that contain ready-to-use Life Cycle Inventory profiles; https://www.gabi-software.com/international/support/gabi-version-history/gabi-ts-version-history/.

7 https://www.ecoinvent.org/.

8 https://www.thinkstep.com/software/gabi-lca.

9 https://www.cepe.org/efede/public.htm#!HTML/29121.

Appendix A