By Dr. Christopher M. Seubert, Ford Research and Innovation Center

As you may have read or heard on television, the automotive industry is working to take the human element out of driving. In the not-so-distant future, fully autonomous vehicles (AVs) will occupy our roads and will transport passengers from location to location. These vehicles will require little human interaction, and will navigate our complicated and dynamic system of roads without incident. At least, that is the goal.

How will coatings play a role in this new automotive landscape? How can the coatings industry prepare? What needs does the AV market have in the area of coatings? Each of these questions will be discussed, but first, some background on autonomy.

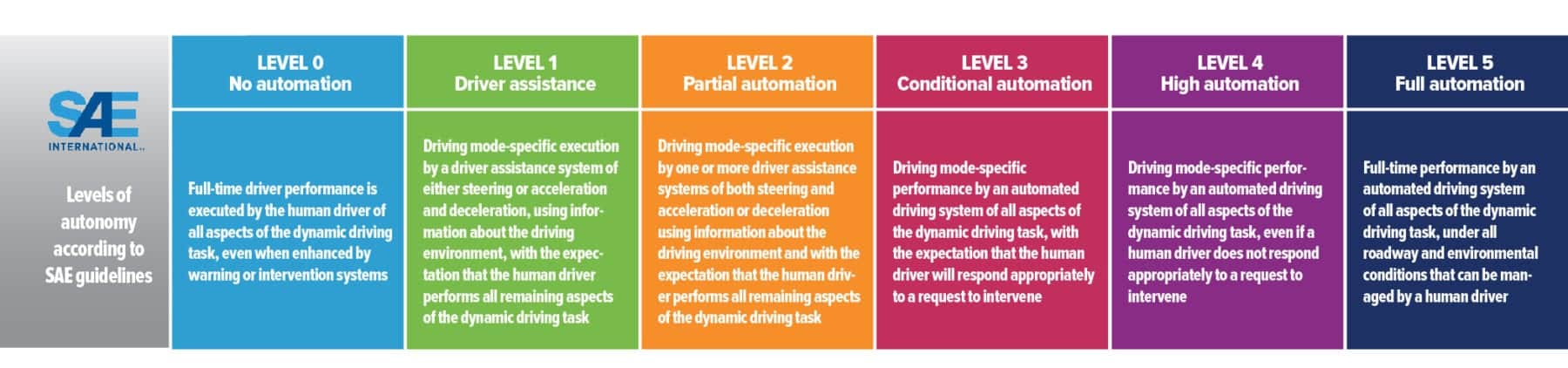

The Society of Automotive Engineers (SAE) refers to a fully autonomous vehicle as Level 5 autonomy. This is not to say that the transition to full autonomy will occur overnight, or that autonomy does not already exist in the automotive industry.

Adaptive cruise control (Level 2), parking assist (Level 3), collision warning system (Level 1), are just a few technologies that can be classified on SAE’s Levels of Autonomy scale (Figure 1).

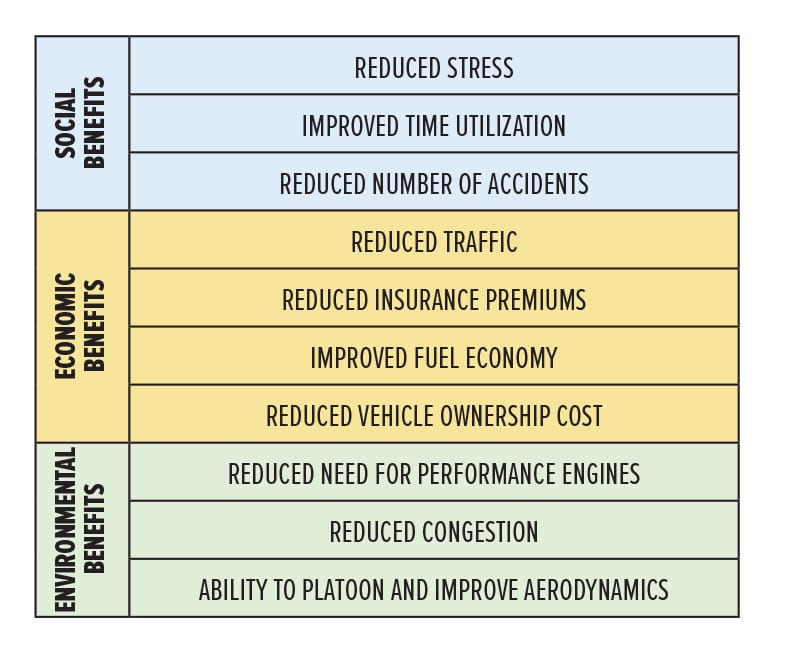

Autonomous vehicles have the potential to provide a range of social, economic, and environmental benefits. A few of these benefits are shown in Figure 2. If drivers turn into simple passengers, they can immediately improve their time utilization and reduce any stress related to driving. Reduced accidents, traffic congestion, and insurance premiums may all result from the optimization of AV driving patterns and behaviors. This optimization can even lead to increased fuel economy and reduced emissions. However, these benefits may not be completely realized until a critical mass of vehicles become autonomous.

FIGURE 1—The six levels of autonomous driving, according to SAE. Most technologies seen on vehicles today do not exceed a Level 3 distinction. Ultimately, the automotive industry would like to achieve Level 5 autonomy.

FIGURE 2—A list of some of the benefits associated with AVs. Each benefit is classified as either social, economic, or environmental, even though some benefits may transcend a single classification. Some of these benefits require a critical mass of AVs to be realized.

The perceived benefits of AVs have translated into consumer interest in autonomous technologies. An MIT AgeLab white paper presented data on the acceptance and interest in autonomous technologies based on age groups.* In general, younger adults are more comfortable with vehicle autonomy compared to older adults. Forty percent of adults between the ages of 25 and 34 said the maximum level of autonomy they would be comfortable with is full autonomy. This percentage drops below 25% for all age groups over 44 years of age. However, over 50% of the older adult market respondents said they are comfortable with technologies that assist the driver in some way. This indicates that a slow, methodical roll-out of autonomous technologies could find a significant customer base across all age groups.

*https://agelab.mit.edu/files/publications/2016_6_Autonomous_Vehicles_Consumer_Preferences.pdf

Government entities, universities, and private companies must work together to create regulations, laws, processes, and technologies that address all of the needs of both the industry and the customer/user.

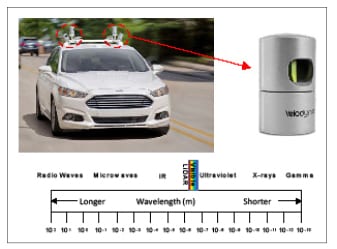

Many of the technologies needed for full autonomy, such as radar, LiDAR (Light Detection and Ranging), high resolution cameras, detailed GPS maps, etc. are still being developed and refined. These technologies, and how they function and interact with the driving environment, will drive coatings research and development for the industry.

From the exterior paint system, to sensor and camera lens coatings, to traffic markings, to refinish coatings, the AVs of tomorrow will rely heavily on coatings technology, some of which will differ significantly from what exists today. Work on these technologies must start soon to be ready for the autonomous vehicles of tomorrow.

Coatings and Autonomy

Exterior Paint

Exterior paint, with a typical surface area larger than any other exterior material, will play a critical role in the AV landscape. First and foremost, any sensor or camera technology used to detect other vehicles must “see” any exterior paint system applied to both AV and non-AV alike. This applies to all colors and gloss levels.

LiDAR sensors, a primary sensor used on AVs, utilize emitted light pulses, typically at 905 nm, to remotely detect the location of objects (Figure 3). Incident light from the LiDAR sensor is both specularly reflected by the clearcoat and absorbed/reflected by pigments in the basecoat. Paint colors that reflect a greater amount of light at 905 nm are more easily detected by LiDAR. Thus, technologies to enhance paint reflectivity at 905 nm, while not affecting the appearance of the paint, are desirable.

In addition to visibility, cabin temperature management may prove important if AVs utilize either hybrid electric or straight electric vehicles (EVs). The total solar reflectivity (TSR) of the paint system could be increased to significantly reduce the cabin temperature of the vehicle. The difference between the cabin temperature of a black and white vehicle has been shown to reach upwards of 6.5oC. This temperature reduction would allow automakers to use smaller air conditioners, reduce weight, and increase fuel economy.

FIGURE 3—Autonomous vehicle with LiDAR units placed on the roof. Also included is the electromagnet spectrum and where LiDAR wavelengths fall on this spectrum.

Sensor and Camera Lenses

The use of multiple sensors and cameras on AVs introduces a new and unique problem, namely, how do you ensure the sensor’s view is not impaired? For a human driver, we simply check our vision occasionally, use glasses as needed, and clean our windows if they become dirty.

AV sensors may not degrade like human vision, but the lenses can certainly become dirty or covered with frost. Washing systems are expensive, but a coating with easy clean or dirt-resistant properties could keep lenses clear, even in the dirtiest environments. Frost-resistant coatings could also be useful in northern climates where warm-up times could be reduced if frost removal is not necessary.

Environmental Coatings

The visibility of coatings to sensors is not restricted to on-vehicle applications. AVs must not only see other vehicles, but also the environment around them, which includes lane markings, street signs, pedestrians, and construction workers.

Coating systems, with pigmentation that can improve the visibility of these objects, are needed. Unlike the exterior paint system, where designers want to achieve a specific color space, lane markings and pedestrian safety vests have greater color flexibility. For these items, maximizing LiDAR visibility could be more important than cosmetic color.

A Fully Autonomous Future

While it will take many years for customers to accept and adopt AVs, there may come a time when all vehicles on the road drive themselves. There is also a very real possibility that as more and more vehicles become autonomous, our use case for cars and trucks will move from ownership to simple rental/temporary use. If customers simply look at AVs as point-to-point transportation, the requirements and usage of these vehicles will change significantly, as will the coatings used on these vehicles.

First, in a fully autonom ous future, the rate of vehicle collisions will be dramatically reduced. This would significantly diminish the automotive refinish paint market. In fact, as we move from owners to simple users, our interest in the color of the AV we are riding in may also diminish, and eliminate the need—or even the desire—for highly chromatic or effect colors. This might reduce the usage of micas, pearlescent, and metallic pigments, and likely lead to an increased usage of simple pigments such as TiO2 (recall our previous cabin temperature discussion).

ous future, the rate of vehicle collisions will be dramatically reduced. This would significantly diminish the automotive refinish paint market. In fact, as we move from owners to simple users, our interest in the color of the AV we are riding in may also diminish, and eliminate the need—or even the desire—for highly chromatic or effect colors. This might reduce the usage of micas, pearlescent, and metallic pigments, and likely lead to an increased usage of simple pigments such as TiO2 (recall our previous cabin temperature discussion).

The ownership to user transition will also result in vehicles that no longer sit idle all day/night with just 30–60 minutes of use each day. Multiple users will enter and exit a single AV each day, and the vehicle has the potential to be driven 24 hours per day, seven days per week. This high-use case might reduce vehicle lifetimes to approximately three years, not the typical 10+ years that we see for vehicles today. This lifetime reduction could decrease the durability requirement of any coating used on the exterior of the vehicle, but may actually increase the durability requirements of the interior coatings, specifically those used on seats and other high traffic surfaces. These surfaces will require coatings that can resist near constant passenger wear, and may also benefit from other improvements, such as easy clean/no stain properties.

Conclusions

Additive and pigment suppliers, coating suppliers, OEMs, and customers must all work together to identify key coating attributes needed by AVs and begin to develop those technologies today. New classes of pigments and additives may be needed, which could require years of development and testing.

CoatingsTech | February 2017 | Vol. 14, No. 2